- Capacity per hour:

- 260 bags

- Outline size(mm):

- 2850 1865 1730 3092

- power (kw):

- 5.5+0.75+0.37

Powder packing machine

LCS—50 series semi powerpacking machine adopts latest technology screw electron weighing portionpacking machine.

It is suited to weighting pack various normal mobility powder.Such as chemical and fertilizer, etc. especially barium carbonate.

It adoptsmodular design, max improve work efficiency; reduce labor intensity, dust andnoise. Control system and pneumatic

components are first-class qualityproducts, software function abundant, simple operation, strong reliability,ensure run one million

times continuous. The series auto quantitative packingmachine includes hopper, feeding device, metering device, unload hopper,

clipbag device, electronic control system, conveyor, and stitch machine, etc. Forma metering packaging sealing production line.

Product parameter

| Name | Parameters | LCS-50A-J-NⅡ (NW single scale) | LCS-50B-J-NⅡ (NW scale) | LCS-50B-Z-NⅡ (Artesian NW scale) | LCS-50A-J-MⅡ (GW single scale) |

LCS series of powder packing equipment | Applicable materials | Various powder materials, such as wet ammonium chloride, ammonium bicarbonate, potash, soda, soda ash, PVC powder, powdered fertilizer, sodium silicate, calcium bicarbonate | |||

Weighing range | 25-50kg | ||||

Weighing speed | 200-250bag/h | 500-800bag/h | 500-600bag/h | 200-250bag/h | |

Weighing accuracy | 0.2 level | ||||

Equipped with a power | AV380V±10% AC220V±10% 50Hz | ||||

Air supply | 0.4Nm/min 0.5~0.6Mpa | ||||

Equipped with power | 6kw | 13kw | 5kw | 6kw | |

Dimensions | Adjusted according to the situation | ||||

Other | Touch screen with full Chinese/English can be changed | ||||

LCS-50FM basic class powder packing machine

LCS—50 series semi powerpacking machine adopts latest technology screw electron weighing portionpacking machine. It is

suited to weighting pack various normal mobility powder.Such as chemical and fertilizer, etc. especially barium carbonate. It adopts

modulardesign, max improve work efficiency; reduce labor intensity, dust and noise.Control system and pneumatic components are

first-class quality products,software function abundant, simple operation, strong reliability, ensure runone million times continuous.

The series auto quantitative packing machineincludes hopper, feeding device, metering device, unload hopper, clip bagdevice,

electronic control system, conveyor, and stitch machine, etc. Form ametering packaging sealing production line.

Main features:

1. Fast packing speed: Depends on theoperator proficiency and material process requirement

2. High measuring accuracy: weightingaccuracy: ±0.2%

3. High reliability: main control systemcomponent is imported product, instrument adopts Jermaine weight technology;pneumatic system

main component adopts CKD/SMC, motor adopts Taiwan brand.

4. Reasonable mechanical structure: goodmaintenance system, material adaptable.

5. Stability product quality assurance:with ISO9001 quality assurance system for the security, adopts advanced CADdesign and CAM

manufacturing technology, andwith the help of the CAT detection means, ensure the product quality.

6. Good after-sales service: the stabletechnical service personnel, 24 hours service hotline, provide enough spareparts and perfect

technical service in a timely manner.

Main function:

Set arbitrary rough and fine feeding value, weighingspeed adjustment, single bag weight value setting, automatic error correction,bag

count, weight accumulative display, dynamic display rough and fine feeding,automatic peeling, automatic zeroing, out-of-tolerance alarm

and faultself-diagnosis function. Also it has the remaining material emptying, manualunloading function, and convenience for the user.

TECHNICAL PARAMETER:

Name | Powder GW single scale | |

Model | LCS-50FM | |

Weighing Scope | 10~50kg/bag | |

Max Packing Capacity | 80~250bag/h | |

Weighing accuracy | 0.2% | |

Introduction | Suitable for powder of basic class or simple physical property | |

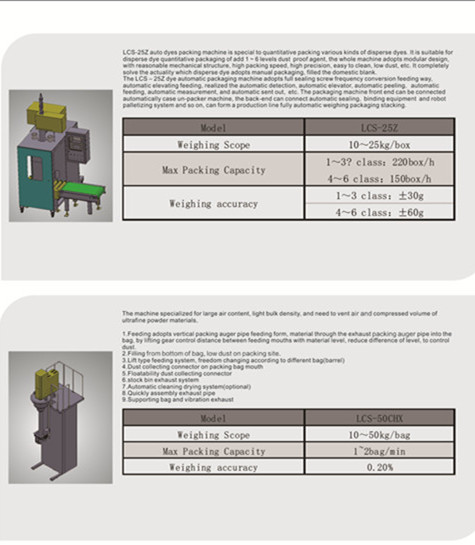

LCS-50CHX strong sticky powder packing machine

LCS—50 series semi powerpacking machine adopts latest technology screw electron weighing portionpacking machine. It is suited to

weighting pack various normal mobility powder.Such as chemical and fertilizer, etc. especially barium carbonate. It adopts modulardesign,

max improve work efficiency; reduce labor intensity, dust and noise.Control system and pneumatic components are first-class quality

products,software function abundant, simple operation, strong reliability, ensure runone million times continuous. The series auto

quantitative packing machineincludes hopper, feeding device, metering device, unload hopper, clip bagdevice, electronic control system,

conveyor, and stitch machine, etc. Form ametering packaging sealing production line.

Main features:

1. Fast packing speed: Depends on theoperator proficiency and material process requirement

2. High measuring accuracy: weightingaccuracy: ±0.2%

3. High reliability: main control systemcomponent is imported product, instrument adopts Jermaine weight technology;pneumatic system main component adopts CKD/SMC, motor adopts Taiwan brand.

4. Reasonable mechanical structure: goodmaintenance system, material adaptable.

5. Stability product quality assurance:with ISO9001 quality assurance system for the security, adopts advanced CADdesign and CAM

manufacturing technology, andwith the help of the CAT detection means, ensure the product quality.

6. Good after-sales service: the stabletechnical service personnel, 24 hours service hotline, provide enough spareparts and perfect

technical service in a timely manner.

Main function:

Set arbitrary rough and fine feeding value,weighing speed adjustment, single bag weight value setting, automatic errorcorrection,

bag count, weight accumulative display, dynamic display rough andfine feeding, automatic peeling, automatic zeroing, out-of-tolerance

alarm andfault self-diagnosis function. Also it has the remaining material emptying,manual unloading function, and convenience for the user.

Technical parameter:

Name | Each clear GW single scale | |

Model | LCS-50CHX | |

Weighing Scope | 10~50kg/bag | |

Max Packing Capacity | 80~250bag/h | |

Weighing accuracy | 0.2% | |

Introduction | Suitable for strong sticky powder | |

LCS-50FTD basic class powder packing machine

LCS—50 series semi powerpacking machine adopts latest technology screw electron weighing portionpacking machine. It is suited to

weighting pack various normal mobility powder.Such as chemical and fertilizer, etc. especially barium carbonate. It adopts modulardesign,

max improve work efficiency; reduce labor intensity, dust and noise.Control system and pneumatic components are first-class quality

products,software function abundant, simple operation, strong reliability, ensure runone million times continuous. The series auto quantitative

packing machineincludes hopper, feeding device, metering device, unload hopper, clip bagdevice, electronic control system, conveyor, and

stitch machine, etc. Form ametering packaging sealing production line.

Main features:

1. Fast packing speed: Depends on theoperator proficiency and material process requirement

2. High measuring accuracy: weightingaccuracy: ±0.2%

3. High reliability: main control systemcomponent is imported product, instrument adopts Jermaine weight technology;pneumatic system main component adopts CKD/SMC, motor adopts Taiwan brand.

4. Reasonable mechanical structure: goodmaintenance system, material adaptable.

5. Stability product quality assurance:with ISO9001 quality assurance system for the security, adopts advanced CADdesign and CAM

manufacturing technology, andwith the help of the CAT detection means, ensure the product quality.

6. Good after-sales service: the stabletechnical service personnel, 24 hours service hotline, provide enough spareparts and perfect

technical service in a timely manner.

Main function:

Set arbitrary rough and fine feeding value,weighing speed adjustment, single bag weight value setting, automatic errorcorrection, bag

count, weight accumulative display, dynamic display rough andfine feeding, automatic peeling, automatic zeroing, out-of-tolerance

alarm andfault self-diagnosis function. Also it has the remaining material emptying,manual unloading function, and convenience for

the user.

Technical parameter:

Name | Powder NW single scale(standing type) | |

Model | LCS-50FTD | |

Weighing Scope | 10~50kg/bag | |

Max Packing Capacity | 80~250bag/h | |

Weighing accuracy | 0.2% | |

Introduction | Suitable for basic class powder | |

LCS-50LSJ large-tonnage basic class powder packing machine

LCS—50 series semi powerpacking machine adopts latest technology screw electron weighing portionpacking machine. It is suited to

weighting pack various normal mobility powder.Such as chemical and fertilizer, etc. especially barium carbonate. It adopts modulardesign,

max improve work efficiency; reduce labor intensity, dust and noise.Control system and pneumatic components are first-class quality

products,software function abundant, simple operation, strong reliability, ensure runone million times continuous. The series auto quantitative

packing machineincludes hopper, feeding device, metering device, unload hopper, clip bagdevice, electronic control system, conveyor, and

stitch machine, etc. Form ametering packaging sealing production line.

Main features:

1. Fast packing speed: Depends on theoperator proficiency and material process requirement

2. High measuring accuracy: weightingaccuracy: ±0.2%

3. High reliability: main control systemcomponent is imported product, instrument adopts Jermaine weight technology;pneumatic system main

component adopts CKD/SMC, motor adopts Taiwan brand.

4. Reasonable mechanical structure: goodmaintenance system, material adaptable.

5. Stability product quality assurance:with ISO9001 quality assurance system for the security, adopts advanced CADdesign and CAM manufacturing

technology, andwith the help of the CAT detection means, ensure the product quality.

6. Good after-sales service: the stabletechnical service personnel, 24 hours service hotline, provide enough spareparts and perfect technical service

in a timely manner.

Main function:

Set arbitrary rough and fine feeding value,weighing speed adjustment, single bag weight value setting, automatic errorcorrection, bag count, weight

accumulative display, dynamic display rough andfine feeding, automatic peeling, automatic zeroing, out-of-tolerance alarm andfault self-diagnosis

function. Also it has the remaining material emptying,manual unloading function, and convenience for the user.

Technical parameter:

Name | Powder NW double scale(standing type) | |

Model | LCS-50LSJ | |

Weighing Scope | 10~50kg/bag | |

Max Packing Capacity | 250~500bag/h | |

Weighing accuracy | 0.2% | |

Introduction | Suitable for large-tonnage basic class powder | |

LCS-50PQX containing gas powder packing machine

LCS—50 series semi powerpacking machine adopts latest technology screw electron weighing portionpacking machine. It is suited to

weighting pack various normal mobility powder.Such as chemical and fertilizer, etc. especially barium carbonate. It adopts modulardesign,

max improve work efficiency; reduce labor intensity, dust and noise.Control system and pneumatic components are first-class quality

products,software function abundant, simple operation, strong reliability, ensure runone million times continuous. The series auto quantitative

packing machineincludes hopper, feeding device, metering device, unload hopper, clip bagdevice, electronic control system, conveyor,

and stitch machine, etc. Form ametering packaging sealing production line.

Main features:

1. Fast packing speed: Depends on theoperator proficiency and material process requirement

2. High measuring accuracy: weightingaccuracy: ±0.2%

3. High reliability: main control systemcomponent is imported product, instrument adopts Jermaine weight technology;pneumatic system main component adopts CKD/SMC, motor adopts Taiwan brand.

4. Reasonable mechanical structure: goodmaintenance system, material adaptable.

5. Stability product quality assurance:with ISO9001 quality assurance system for the security, adopts advanced CADdesign and CAM manufacturing technology, andwith the help of the CAT detection means, ensure the product quality.

6. Good after-sales service: the stabletechnical service personnel, 24 hours service hotline, provide enough spareparts and perfect technical service in a timely manner.

Main function:

Set arbitrary rough and fine feeding value,weighing speed adjustment, single bag weight value setting, automatic errorcorrection, bag count, weight accumulative display, dynamic display rough andfine feeding, automatic peeling, automatic zeroing, out-of-tolerance alarm andfault self-diagnosis function. Also it has the remaining material emptying,manual unloading function, and convenience for the user.

Technical parameter:

Name |

| |

Model | LCS-50PQX | |

Weighing Scope | 10~50kg/bag | |

Max Packing Capacity | 250~550bag/h | |

Weighing accuracy | 0.2% | |

Introduction | Suitable for containing gas powder | |

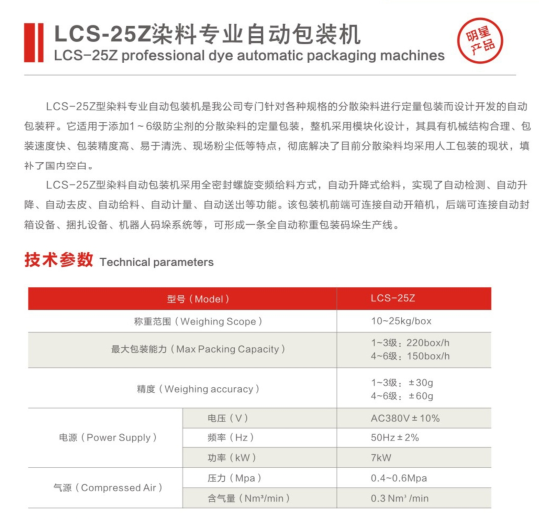

LCS-50BTH white carbon black or carbon black powder packing machine

LCS—50 series semi powerpacking machine adopts latest technology screw electron weighing portionpacking machine. It is suited to

weighting pack various normal mobility powder.Such as chemical and fertilizer, etc. especially barium carbonate. It adopts modulardesign,

max improve work efficiency; reduce labor intensity, dust and noise.Control system and pneumatic components are first-class quality

products,software function abundant, simple operation, strong reliability, ensure runone million times continuous. The series auto quantitative

packing machineincludes hopper, feeding device, metering device, unload hopper, clip bagdevice, electronic control system, conveyor, and stitch

machine, etc. Form ametering packaging sealing production line.

Technical parameter:

Name | Screw superfine powder single scale | |

Model | LCS-50BTH | |

Weighing Scope | 10~50kg/bag | |

Max Packing Capacity | 80~150bag/h | |

Weighing accuracy | 0.2% | |

Introduction | Suitable for white carbon black or carbon black powder | |

LCS-50SXJ small yields containing gas powder packing machine

LCS—50 series semi powerpacking machine adopts latest technology screw electron weighing portionpacking machine. It is suited to

weighting pack various normal mobility powder.Such as chemical and fertilizer, etc. especially barium carbonate. It adopts modulardesign,

max improve work efficiency; reduce labor intensity, dust and noise.Control system and pneumatic components are first-class quality

products,software function abundant, simple operation, strong reliability, ensure runone million times continuous. The series auto quantitative

packing machineincludes hopper, feeding device, metering device, unload hopper, clip bagdevice, electronic control system, conveyor, and stitch

machine, etc. Form ametering packaging sealing production line

Main features:

1. Fast packing speed: Depends on theoperator proficiency and material process requirement

2. High measuring accuracy: weightingaccuracy: ±0.2%

3. High reliability: main control systemcomponent is imported product, instrument adopts Jermaine weight technology;pneumatic system main component adopts CKD/SMC, motor adopts Taiwan brand.

4. Reasonable mechanical structure: goodmaintenance system, material adaptable.

5. Stability product quality assurance:with ISO9001 quality assurance system for the security, adopts advanced CADdesign and CAM manufacturing technology, andwith the help of the CAT detection means, ensure the product quality.

6. Good after-sales service: the stabletechnical service personnel, 24 hours service hotline, provide enough spareparts and perfect technical service in a timely manner.

Main function:

Set arbitrary rough and fine feeding value,weighing speed adjustment, single bag weight value setting, automatic errorcorrection, bag count, weight accumulative display, dynamic display rough andfine feeding, automatic peeling, automatic zeroing, out-of-tolerance alarm andfault self-diagnosis function. Also it has the remaining material emptying,manual unloading function, and convenience for the user.

Technical parameter:

Name | containing gas GW single scale | |

Model | LCS-50SXJ | |

Weighing Scope | 10~50kg/bag | |

Max Packing Capacity | 80~200bag/h | |

Weighing accuracy | 0.2% | |

Introduction | Suitable for small yields containing gas powder | |

LCS-50CHX high mesh powder packing machine

LCS—50 series semi powerpacking machine adopts latest technology screw electron weighing portionpacking machine. It is suited to

weighting pack various normal mobility powder.Such as chemical and fertilizer, etc. especially barium carbonate. It adopts modulardesign,

max improve work efficiency; reduce labor intensity, dust and noise.Control system and pneumatic components are first-class quality

products,software function abundant, simple operation, strong reliability, ensure runone million times continuous. The series auto quantitative

packing machineincludes hopper, feeding device, metering device, unload hopper, clip bagdevice, electronic control system, conveyor, and stitch

machine, etc. Form ametering packaging sealing production line.

Main features:

1. Fast packing speed: Depends on theoperator proficiency and material process requirement

2. High measuring accuracy: weightingaccuracy: ±0.2%

3. High reliability: main control systemcomponent is imported product, instrument adopts Jermaine weight technology;pneumatic system main component adopts CKD/SMC, motor adopts Taiwan brand.

4. Reasonable mechanical structure: goodmaintenance system, material adaptable.

5. Stability product quality assurance:with ISO9001 quality assurance system for the security, adopts advanced CADdesign and CAM manufacturing technology, andwith the help of the CAT detection means, ensure the product quality.

6. Good after-sales service: the stabletechnical service personnel, 24 hours service hotline, provide enough spareparts and perfect technical service in a timely manner.

Main function:

Set arbitrary rough and fine feeding value,weighing speed adjustment, single bag weight value setting, automatic errorcorrection, bag count, weight accumulative display, dynamic display rough andfine feeding, automatic peeling, automatic zeroing, out-of-tolerance alarm andfault self-diagnosis function. Also it has the remaining material emptying,manual unloading function, and convenience for the user.

Technical parameter:

Name | Powder NW three scales (platform) | |

Model | LCS-50CHX | |

Weighing Scope | 10~50kg/bag | |

Max Packing Capacity | 800~250bag/h | |

Weighing accuracy | 0.2% | |

Introduction | Suitable for high mesh powder | |

LCS-50PJP3 big yields powder packing machine

LCS—50 series semi powerpacking machine adopts latest technology screw electron weighing portionpacking machine. It is suited to

weighting pack various normal mobility powder.Such as chemical and fertilizer, etc. especially barium carbonate. It adopts modulardesign,

max improve work efficiency; reduce labor intensity, dust and noise.Control system and pneumatic components are first-class quality

products,software function abundant, simple operation, strong reliability, ensure runone million times continuous. The series auto quantitative

packing machineincludes hopper, feeding device, metering device, unload hopper, clip bagdevice, electronic control system, conveyor, and

stitch machine, etc. Form ametering packaging sealing production line.

Main features:

1. Fast packing speed: Depends on theoperator proficiency and material process requirement

2. High measuring accuracy: weightingaccuracy: ±0.2%

3. High reliability: main control systemcomponent is imported product, instrument adopts Jermaine weight technology;pneumatic system main component adopts CKD/SMC, motor adopts Taiwan brand.

4. Reasonable mechanical structure: goodmaintenance system, material adaptable.

5. Stability product quality assurance:with ISO9001 quality assurance system for the security, adopts advanced CADdesign and CAM manufacturing technology, andwith the help of the CAT detection means, ensure the product quality.

6. Good after-sales service: the stabletechnical service personnel, 24 hours service hotline, provide enough spareparts and perfect technical service in a timely manner.

Main function:

Set arbitrary rough and fine feeding value,weighing speed adjustment, single bag weight value setting, automatic errorcorrection, bag count, weight accumulative display, dynamic display rough andfine feeding, automatic peeling, automatic zeroing, out-of-tolerance alarm andfault self-diagnosis function. Also it has the remaining material emptying,manual unloading function, and convenience for the user.

Technical parameter:

Name | Powder NW three scales (platform) | |

Model | LCS-50PJP3 | |

Weighing Scope | 10~50kg/bag | |

Max Packing Capacity | 550~750bag/h | |

Weighing accuracy | 0.2% | |

Introduction | Suitable for big yields powder | |

LCS-50SAD stickiness and caustic powder packing machine

LCS—50 series semi powerpacking machine adopts latest technology screw electron weighing portionpacking machine. It is suited to

weighting pack various normal mobility powder.Such as chemical and fertilizer, etc. especially barium carbonate. It adopts modulardesign,

max improve work efficiency; reduce labor intensity, dust and noise.Control system and pneumatic components are first-class quality

products,software function abundant, simple operation, strong reliability, ensure runone million times continuous. The series auto quantitative

packing machineincludes hopper, feeding device, metering device, unload hopper, clip bagdevice, electronic control system, conveyor, and stitch

machine, etc. Form ametering packaging sealing production line.

Main features:

1. Fast packing speed: Depends on theoperator proficiency and material process requirement

2. High measuring accuracy: weightingaccuracy: ±0.2%

3. High reliability: main control systemcomponent is imported product, instrument adopts Jermaine weight technology;pneumatic system main component adopts CKD/SMC, motor adopts Taiwan brand.

4. Reasonable mechanical structure: goodmaintenance system, material adaptable.

5. Stability product quality assurance:with ISO9001 quality assurance system for the security, adopts advanced CADdesign and CAM manufacturing technology, andwith the help of the CAT detection means, ensure the product quality.

6. Good after-sales service: the stabletechnical service personnel, 24 hours service hotline, provide enough spareparts and perfect technical service in a timely manner.

Main function:

Set arbitrary rough and fine feeding value,weighing speed adjustment, single bag weight value setting, automatic errorcorrection, bag count, weight accumulative display, dynamic display rough andfine feeding, automatic peeling, automatic zeroing, out-of-tolerance alarm andfault self-diagnosis function. Also it has the remaining material emptying,manual unloading function, and convenience for the user.

Technical parameter:

Name | Sticking powder single scale (platform) | |

Model | LCS-50SAD | |

Weighing Scope | 10~50kg/bag | |

Max Packing Capacity | 200~250bag/h | |

Weighing accuracy | 0.2% | |

Introduction | Suitable for stickiness and caustic powder | |

LCS-50FTC vibration air exhaust powder packing machine

LCS—50 series semi powerpacking machine adopts latest technology screw electron weighing portionpacking machine. It is suited to

weighting pack various normal mobility powder.Such as chemical and fertilizer, etc. especially barium carbonate. It adopts modulardesign,

max improve work efficiency; reduce labor intensity, dust and noise.Control system and pneumatic components are first-class quality

products,software function abundant, simple operation, strong reliability, ensure runone million times continuous. The series auto

quantitative packing machineincludes hopper, feeding device, metering device, unload hopper, clip bagdevice, electronic control system,

conveyor, and stitch machine, etc. Form ametering packaging sealing production line.

Main features:

1. Fast packing speed: Depends on theoperator proficiency and material process requirement

2. High measuring accuracy: weightingaccuracy: ±0.2%

3. High reliability: main control systemcomponent is imported product, instrument adopts Jermaine weight technology;pneumatic

system main component adopts CKD/SMC, motor adopts Taiwan brand.

4. Reasonable mechanical structure: goodmaintenance system, material adaptable.

5. Stability product quality assurance:with ISO9001 quality assurance system for the security, adopts advanced CADdesign and

CAM manufacturing technology, andwith the help of the CAT detection means, ensure the product quality.

6. Good after-sales service: the stabletechnical service personnel, 24 hours service hotline, provide enough spareparts and perfect

technical service in a timely manner.

Main function:

Set arbitrary rough and fine feeding value,weighing speed adjustment, single bag weight value setting, automatic errorcorrection, bag count, weight accumulative display, dynamic display rough andfine feeding, automatic peeling, automatic zeroing, out-of-tolerance alarm andfault self-diagnosis function. Also it has the remaining material emptying,manual unloading function, and convenience for the user.

Technical parameter:

Name | Air exhaust GW single scale | |

Model | LCS-50FTC | |

Weighing Scope | 10~50kg/bag | |

Max Packing Capacity | 100~200bag/h | |

Weighing accuracy | 0.2% | |

Introduction | Suitable for vibration air exhaust powder | |

The1year

The1year

Animal feed machine

Animal feed machine

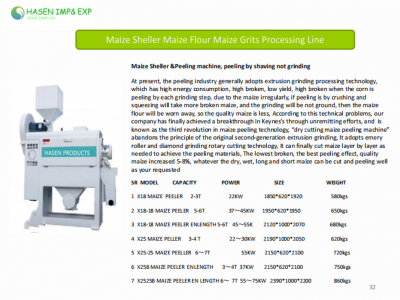

maize peel sheller

maize peel sheller

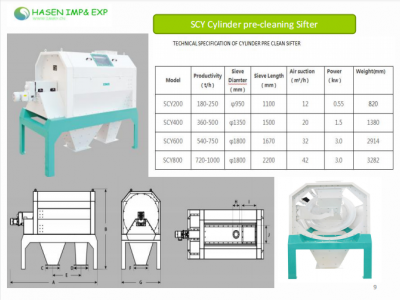

DISC CYLINDER SEPARATOR

DISC CYLINDER SEPARATOR

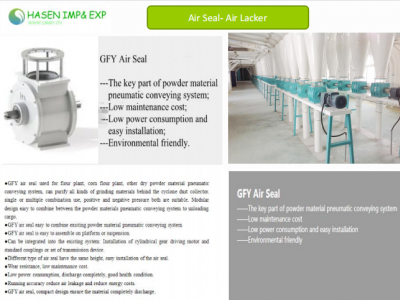

AIR LOCKER For maize flour

AIR LOCKER For maize flour

MOISTURE MEASURING DEVICE

MOISTURE MEASURING DEVICE

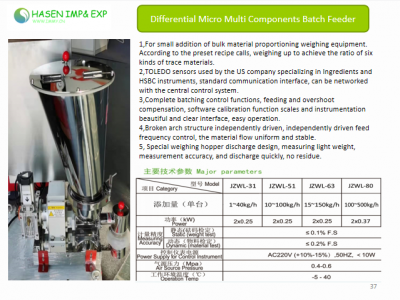

Multi vitamin batch feeder

Multi vitamin batch feeder

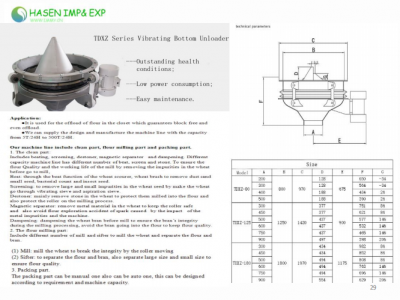

Vibro Bottom Unloader

Vibro Bottom Unloader

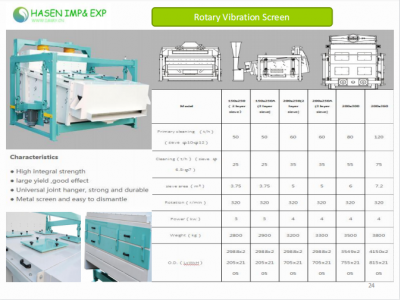

Rotation sifter maize clean

Rotation sifter maize clean