- Working width:

- 2m or 4m

- Supply electricity:

- 380V

- Mechanical speed:

- 2-10m/min

Introduction

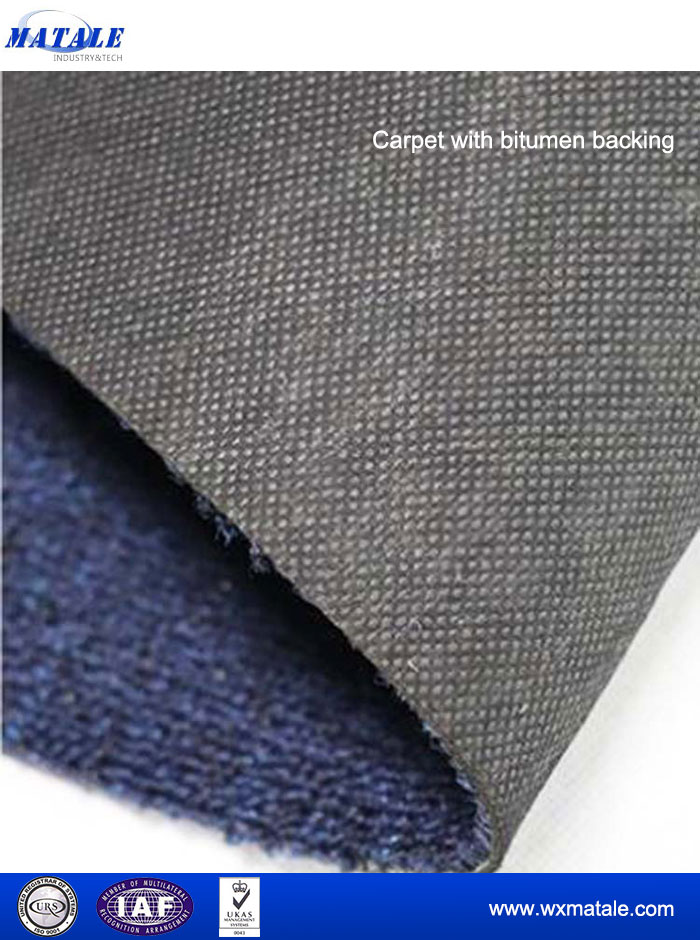

Bitumen coating and lamination line is specially designed for carpet tile production. It is running with bitumen material, that can bring down the cost of product without sacrifice quality of carpet tile. This machine is widely used in carpet tile industry.

Parameters:

1. Valid width:1.2~4.2m

2. Max. Speed is 12m/min

3. Heat method: thermal oil or natural gas

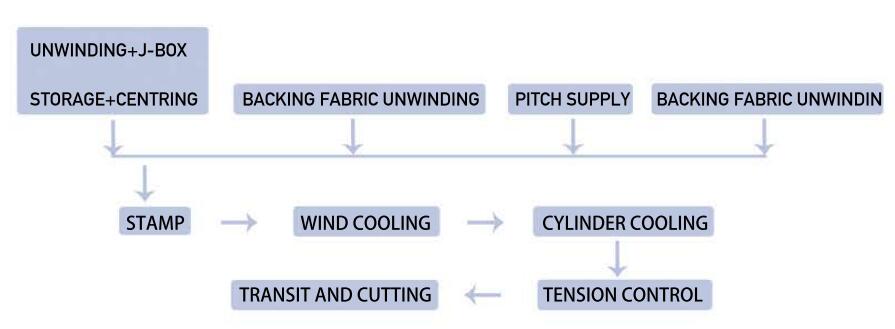

GENERAL PROCESS:

Bitumen stirring unit, fabric unwinding and centring unit, back fabric and glass fabric unwinding unit, bitumen coating unit, fan cooling unit, cylinder cooling unit, tension control unit.

Product photo

Company profile

Matale's philosophy is to focus on the development of professional technology, the innovation of professional products and the world class level sales team aiming to provide better service to our customers in the flooring industry.

Matale, proudly made in China, will always be committed to the research and development on all unique tufting machines and ancillary equipment. Our reliable product quality standard system have brought customers worldwide and we will continue our reputable to meet the market demands. Matale has full range of tufting machines from basic plain loop, plain cut series, multi loop series, LCL FRS series, ICN series and other patterning tailer-made machines for all applications from wall to wall, residential and contracted tiles.

Shipping and delivery

The1year

The1year

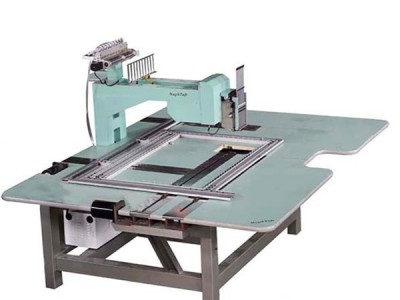

Loop pile tufting machine

Loop pile tufting machine