- degree of automation:

- Fully automatic control

- way to heat up:

- steam

- Sterilization method:

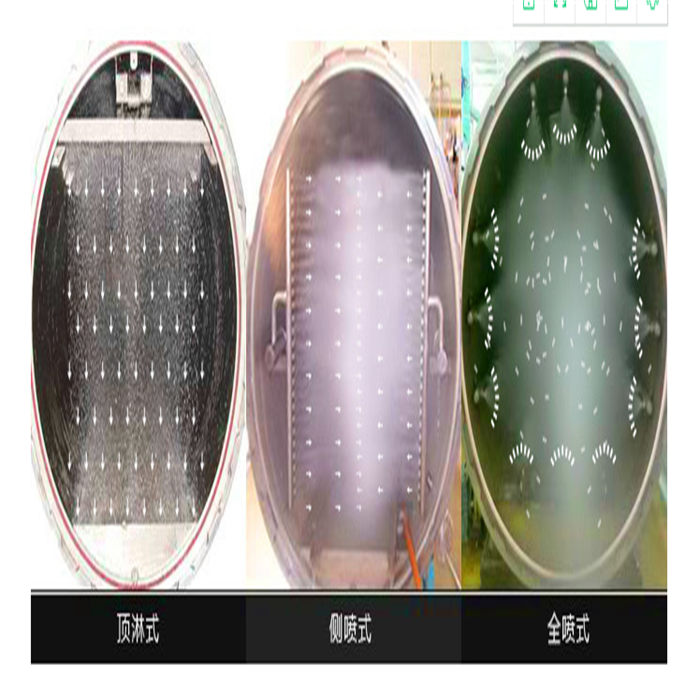

- spray

The box-type bowl-type special sterilizer we call is actually a spray-type sterilizer, which can directly heat up and indirectly cool down, or indirectly heat up and cool down indirectly. Direct heating means that the steam is directly introduced into the pot to heat the process water, indirect heating means that the steam passes through the plate heat exchanger to heat the process water in the pot, and indirect cooling means that the cooling water outside the pot passes through the plate heat exchanger to heat up the process water. The process water in the pot is cooled down. The special box-type sterilizer can be added with a process water storage tank according to the temperature of the product. If the temperature of the product is relatively high, such as 60 degrees, if we use cold water to reheat it, the heat energy will be lost, and the heating time is still long. Therefore, for products with relatively high initial temperature, we install a hot water tank on the sterilization, and the temperature is kept above 60 degrees. The hot water is sprayed onto the surface of the product through pipes and nozzles for heating.

The1year

The1year

Automatic pipe bending machine

Automatic pipe bending machine

Pipe shinking machine

Pipe shinking machine

Automatic intelligent parallel co

Automatic intelligent parallel co

Liangpi machine Liangfen machine

Liangpi machine Liangfen machine

7 tons hydraulic Uncoiler Machine

7 tons hydraulic Uncoiler Machine

Jaw crusher

Jaw crusher

Single plate paper cup machine

Single plate paper cup machine

reverse osmosis water purificatio

reverse osmosis water purificatio