- 5000*450:

- 60000*550CM

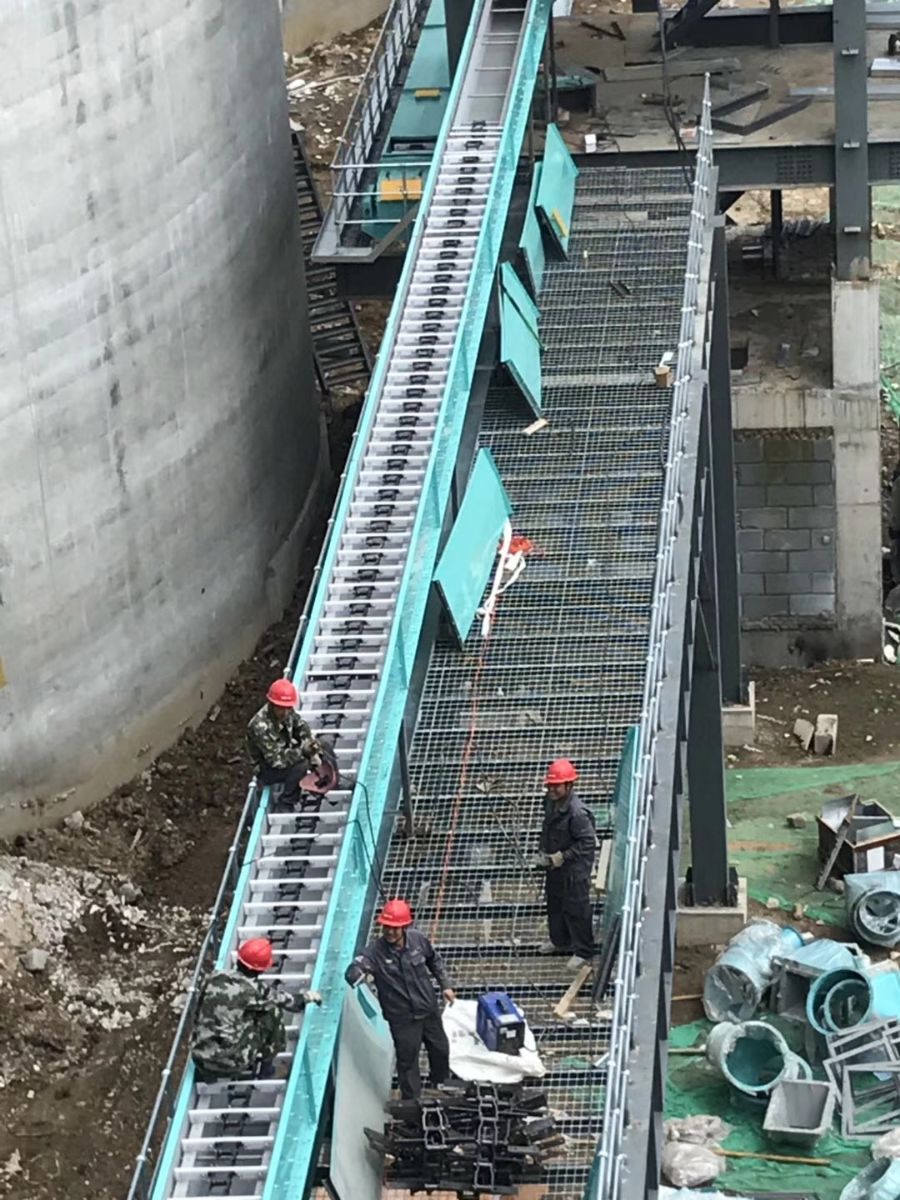

LARGE SCALE GRAIN ConVEYOR SYSTEM

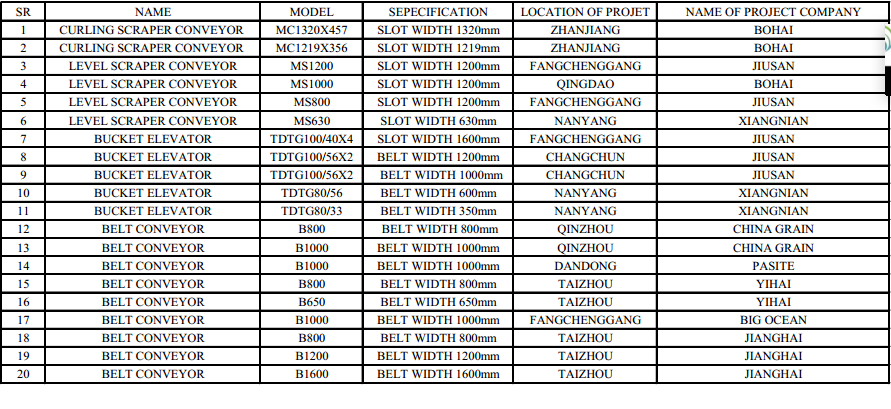

PROJECT CASES LIST IN OUR COMPANY:

ENGINEERING PERFORMANCE LIST FROM OUR COMPANY

PROBLEM DURING PROJECT RUNNING AND SOLUTION FOR GRAIN ConVEYOR SYSTEMS:

During working on those above projects, mostly problem are related to belt deviation(belt side skid),

so we analysis the problem what happened in each specified cases: in case :

1, BOHAI project, its curling Scraper conveyor, model 320*457, slot width 1320mm, located in Zhanjiang,

Guangdong province,belong to BOHAI GROUP OF COMPANY, used in oil pocessing project, in this case,

scraper has jump chain problem, we tighten the tail screw,, strength chain, so the problem solved.

In case 7, bucket elevator,TDTG100/40X4, SLOT WIDTH 1600mm, its located in FANGCHENGGANG,

GUANGXI province, belong to JIUSAN group of company, there are some proble relate to: 1, belt side

run-off: the belt on both sides of the loose tension is not consistent, adjust the tail screw so that the

tightness is consistent; 2, Material return large: the bucket belt and the bezel gap is too large, adjust the

bezel position; 3, the outlet slip pipe blockage: clean out the blockage of foreign body, foreign body for a

bucket. Check all buckets and secure them; 4, head bearing noise: open the bearing chamber, found that

the bearing lock sleeve is not locked in due place, re-locking to the appropriate position;

In case 18, BUCKET ELEVATOR, B800, BELT WIDTH 800mm, location is in TAIZHOU, JIANGSU

province, Belong to JIANGHAI GRAIN&OIL GROUP OF COMPANY, the problem is leakege of

oil in reducer box, the reason of leakage of oil are: Seal aging failure after a long time running; Pressure

cap screw loose, gasket failed;The oil hole bolts are not tight, we check it one by one point and put action

on: Replace the seal; Change the gasket tight oil seal; Tight bolts and seals, of course the problem solved;

In case 20,BELT CONVEYOR, B 1600, BELT WIDTH 1600mm, Location is in TAIZHOU, JIANGSU

province, belong to JIANGHAI GRAIN AND OIL GROUP OF COMPANY, The problem found out is the

roll is not spinning well, the joint wear is broken, the bearing heat,we take action on the following:

Cleaning bearings or replacing rollers; Re-bonding; teasing bearing cover screws;Check the

play, correct the bearing position, adjust the belt tightness degree;

After all, we would like to say that We have rich experiences in grain conveyor

researching,manufacturing and installation,commissioning in all types of grain

and oil conveyors, we have strong backbase of technical support from National

grain machine instutites and academies and some experienced grain conveyor

chief technicians &engineers in CHina and world, we believe we can work with

you very smoothly in your project! Thanks!

The1year

The1year

Sesame processing plant

Sesame processing plant

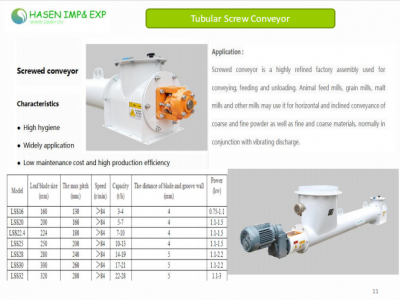

DISC CYLINDER SEPARATOR

DISC CYLINDER SEPARATOR

Cattle feed machine

Cattle feed machine

Oats Flakes Production Line

Oats Flakes Production Line

Buckwheat Seed Machine

Buckwheat Seed Machine

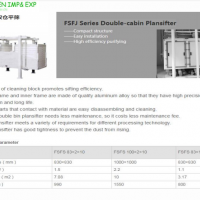

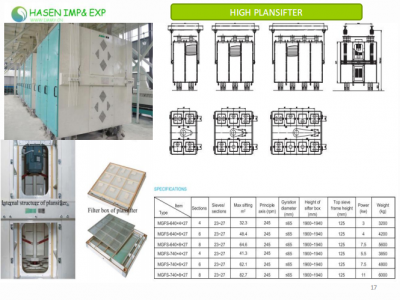

high plansifter for maize mill

high plansifter for maize mill

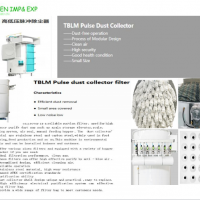

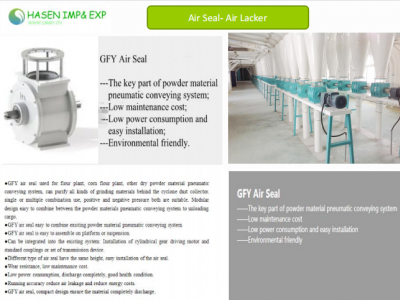

AIR LOCKER For maize flour

AIR LOCKER For maize flour