- 1000*250:

- 2600*1800*2800CM

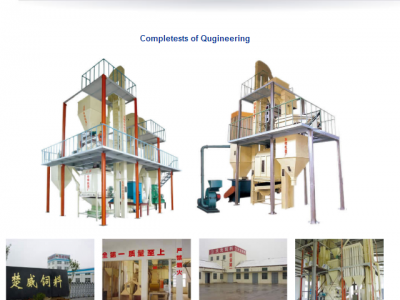

Lentil Peeling, Splitting and Grinding Plant WUXI HASEN Lentil Peeling, Splitting and Grinding Plant adopts excellent automatic solutions and can reduce labor cost and production cost. Meanwhile, it can reduce the influence from impurities, dust and bran. Bean Peeling, Splitting and Grinding Plant can process soybean, broad bean, lentil, cowpea, mung bean, black soya bean, kidney bean and other beans.

The complete Lentil Peeling, Splitting and Grinding Plant has the features of advanced technology, strong specificity, reasonable layout, low energy consumption, high yield, low breakage rate, high quality of end products, automatic and continuous production. This bean processing line can produce polished and graded beans, peeled and graded bean kernels, graded bean grits and graded bean flour. It is widely used in food and grain processing enterprises. And the core equipments have obtained the national patents. Technology introduction of Lentil Peeling, Splitting and Grinding Plant:

designed this bean processing plant. It realizes the value of bean processing from bean cleaning, bean color sorting, bean peeling and splitting, and bean flour milling. Technological process of Lentil Peeling, Splitting and Grinding Plant:

magnetic separation section, and removes the big, small and light impurities, pebbles and magnetic material from the beans to ensure the quality of the end products.

shriveled beans and foreign species of beans according to the color and luster feature of the beans.

technology (it can utilize the segregation valve to choose peeling and brushing according to the material character.)

and collect corn kernels by effective aspiration system;

4. Grading section: it adopts different screens and classify the material into different grades according to the size. 5. Lentil kernel making and grits milling section: it adopts the technology of three peeling sections, one grits making section, grading and suspension. 1)Peeling section: it can remove the bean bran and separate and collect it by effective aspiration system and produce peeled kernels;

kernels or bean grits into different grades according to the size.

6. Bean flour milling section: it adopts the technology of burdening, several processes of grinding and screening and grading.

products;

7. Measuring and packaging section: storage can reduce the amount of labor used. Measuring can be artificial or electronic.

End products of Lentil Peeling, Splitting and Grinding Plant:

kidney and other beans processing.

pure bean taste. Advantages :

according to your requirements and different grain species.

can supply you with thorough systematic engineering service, such as project design,

manufacturing, installation, debugging, training and after-sales service. Lentil Peeling, Splitting and Grinding Plant Technical parameter: Application Overseas (Part) :

20 Sets of Chickpea Peeling Machines Delivery:

|

The1year

The1year

IMPACT DETACHER

IMPACT DETACHER

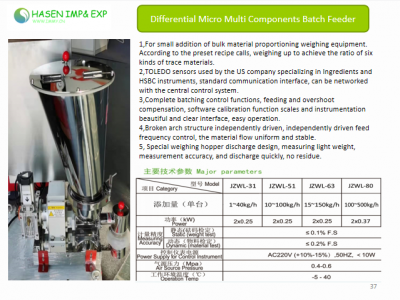

Multi vitamin batch feeder

Multi vitamin batch feeder

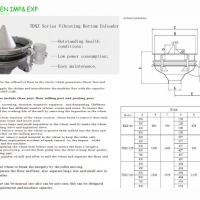

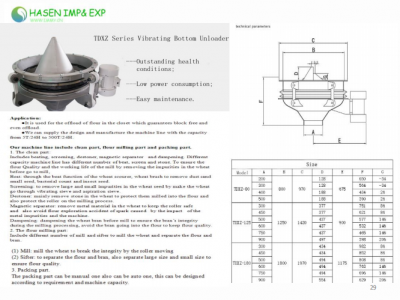

Vibro Bottom Unloader

Vibro Bottom Unloader

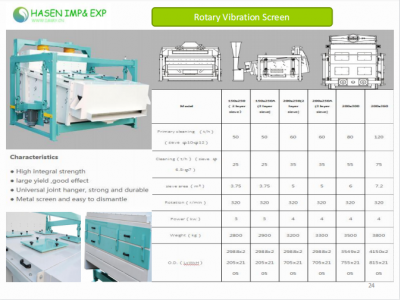

Rotation sifter maize clean

Rotation sifter maize clean

Roller Mill flour machine

Roller Mill flour machine

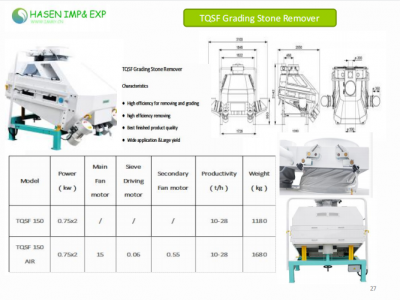

TQSF Destoner MAIZE FLOUR MILL

TQSF Destoner MAIZE FLOUR MILL

100TPD MAIZE FLOUR MACHINE

100TPD MAIZE FLOUR MACHINE