1. Milled Steel Teeth: Steel teeth tricone bits are equipped with milled steel teeth that are designed to effectively cut and break apart rock formations during drilling. These teeth are typically shaped like wedges or chisels and are strategically placed on the cones for optimal cutting action.

2. Durability: Steel teeth tricone bits are known for their durability and resistance to wear. The steel teeth are hardened to withstand the high impact and abrasion encountered while drilling through various formations.

3. Versatility: Steel teeth tricone bits are versatile and can be used in a wide range of formations, including soft to medium-hard formations. They perform well in formations that are less abrasive and can effectively break apart the rock for efficient drilling.

4. Aggressive Cutting: The sharp steel teeth on the tricone bit provide an aggressive cutting action, making them effective in harder formations that require greater force for drilling.

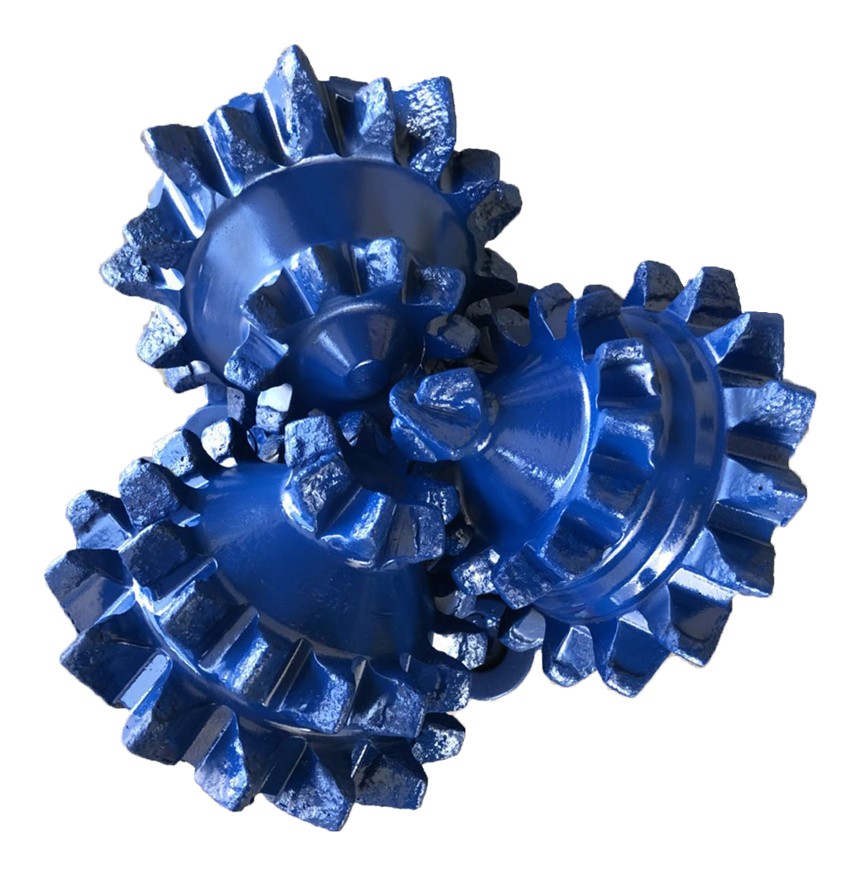

A steel teeth tricone bit, also known as a milled tooth tricone bit, is a type of rotary drilling tool used in the oil and gas industry, mining, water well drilling, and other drilling applications. It is designed to effectively drill through different rock formations, including soft to medium-hard formations.

The key feature of a steel teeth tricone bit is the presence of steel teeth or cones on the bit. These cones are equipped with milled steel teeth that are shaped like sharp wedges or chisels. The teeth are strategically placed on the cones to provide efficient cutting action during drilling.

The steel teeth on a tricone bit work by gouging, scraping, and chipping away at the rock formation. As the bit rotates, the cones roll and the teeth come into contact with the rock, breaking it apart and creating a borehole.

Steel teeth tricone bits are known for their durability and versatility. They are suitable for drilling in various formations, including soft and abrasive formations where other types of bits may struggle. The design of the steel teeth allows for aggressive cutting action, making them effective in tackling harder formations.

However, steel teeth tricone bits may have limitations in drilling through harder and more abrasive formations. In such cases, other types of tricone bits with tungsten carbide inserts or diamond-enhanced bits may be more appropriate.

It's important to select the right type and size of tricone bit based on the specific drilling requirements, including the formation characteristics, desired drilling speed, and bit longevity. Proper maintenance, sharpening, and monitoring of the cutting structure are also important to ensure optimal performance and extended bit life.

Here are some key features of steel teeth tricone bits:

1. Milled Steel Teeth: Steel teeth tricone bits are equipped with milled steel teeth that are designed to effectively cut and break apart rock formations during drilling. These teeth are typically shaped like wedges or chisels and are strategically placed on the cones for optimal cutting action.

2. Durability: Steel teeth tricone bits are known for their durability and resistance to wear. The steel teeth are hardened to withstand the high impact and abrasion encountered while drilling through various formations.

3. Versatility: Steel teeth tricone bits are versatile and can be used in a wide range of formations, including soft to medium-hard formations. They perform well in formations that are less abrasive and can effectively break apart the rock for efficient drilling.

4. Aggressive Cutting: The sharp steel teeth on the tricone bit provide an aggressive cutting action, making them effective in harder formations that require greater force for drilling.

5. Enhanced Cleaning Action: Steel teeth tricone bits have a self-cleaning action due to the design of the teeth. As the bit rotates, the teeth scrape away the drilled cuttings from the formation, allowing for improved drilling performance.

6. Size Variety: Steel teeth tricone bits are available in various sizes to accommodate different drilling needs. Choosing the right bit size is crucial to achieve optimal drilling performance and ensure efficient rock penetration.

7. Compatibility: Steel teeth tricone bits are compatible with standard rotary drilling systems commonly used in the industry. They can be easily attached to the drill string and used with drilling tools such as drill collars and drilling mud systems.

It's important to note that while steel teeth tricone bits are effective for certain drilling applications, they may not perform well in highly abrasive or hard rock formations. In such cases, other types of tricone bits or alternative drilling methods may be more suitable. Proper maintenance and monitoring of the bit's wear and cutting structure are also recommended to maximize performance and longevity.

The1year

The1year

R32 Drifter Drill Rod

R32 Drifter Drill Rod

Y19A Jack Hammer

Y19A Jack Hammer

8 Inch DTH Hammer

8 Inch DTH Hammer

Steel Tooth Tricone Bit Oil Drill

Steel Tooth Tricone Bit Oil Drill

T45 Thread Shanks Adapter

T45 Thread Shanks Adapter

Precision Drill Rods

Precision Drill Rods

YT28 Air Leg Rock Drill

YT28 Air Leg Rock Drill

Precision Rock Specialty DTH Bits

Precision Rock Specialty DTH Bits

GT60 Thread Retract Button Bit

GT60 Thread Retract Button Bit