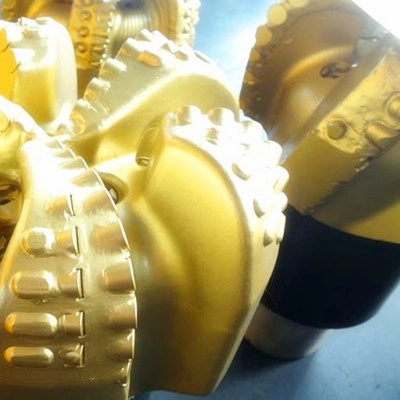

The strategic placement of polycrystalline diamond inserts within high-performance PDC bits is a result of meticulous engineering, ensuring that each insert is positioned to maximize its cutting efficiency. This precision engineering allows the PDC bit to maintain consistent and precise penetration across a wide range of rock formations, contributing to enhanced drilling performance and overall efficiency.

Enhanced Hardness and Abrasion Resistance: The polycrystalline diamond inserts in high-performance PDC bits are engineered to exhibit exceptional hardness and abrasion resistance. This superior material strength enables the inserts to withstand the extreme forces and wear encountered during drilling, ensuring prolonged durability and sustained cutting effectiveness even in challenging geological formations.

Thermal Stability for Consistent Performance: The advanced diamond cutter design in high-performance PDC bits incorporates thermal stability as a key feature. This thermal resilience allows the polycrystalline diamond inserts to maintain their cutting effectiveness even in high-temperature drilling environments, ensuring consistent performance and minimizing the risk of premature wear or degradation. The thermal stability of the diamond inserts contributes to the optimized efficiency and longevity of the PDC bits during demanding drilling operations.

The1year

The1year

6 Inch DTH Hammer

6 Inch DTH Hammer

T38 Thread Shank Adapter

T38 Thread Shank Adapter

Button Drill Bit

Button Drill Bit

YT28 Air Leg Rock Drill

YT28 Air Leg Rock Drill

T51 Thread Coupling Sleeve

T51 Thread Coupling Sleeve

YN27C Gasoline Rock Drill Machine

YN27C Gasoline Rock Drill Machine

Precision Rock Specialty DTH Bits

Precision Rock Specialty DTH Bits

Precision Drill Rods

Precision Drill Rods

Highly Wear Resistant Spiral Pdc

Highly Wear Resistant Spiral Pdc