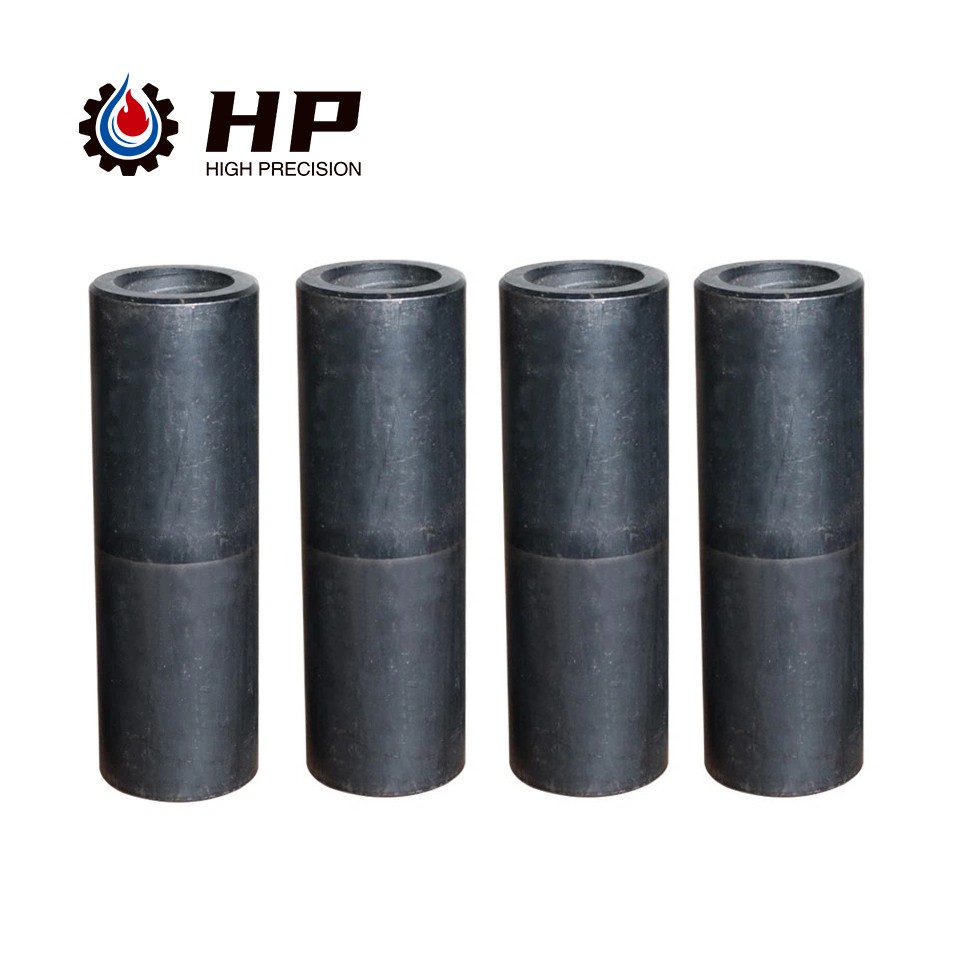

1. Cross-shaped design: The cross-shaped design of the drill bit, with four raised carbide inserts arranged in a cross pattern, provides multiple cutting edges. This design allows for efficient rock penetration and breaking.

2. Carbide inserts: The carbide inserts on the cross bits are made from durable and wear-resistant materials, such as tungsten carbide. These inserts provide the necessary hardness and strength to withstand the high impact and abrasion encountered during rock drilling.

3. Versatility: Rock drilling cross bits are designed to be versatile and adaptable to different drilling methods and rock formations. They can be used with pneumatic or hydraulic rock drills and are suitable for various drilling techniques, including rotary drilling and percussion drilling.

4. Compatibility: Rock drilling cross bits are available in different sizes and shapes to fit various drilling rigs and equipment. This ensures compatibility and enables users to select the appropriate cross bit for their specific drilling conditions.

Rock drilling cross bits are the main varieties of the international flake series of bits. The diameter of the bit is in the range of D29-D48mm, and it has a strong adaptability to rock drilling conditions, and is almost not limited by the type of rock drill or the nature of the rock body. The alloy is brazed and is a lightweight drill bit, also mostly used in steel mills to open the blast furnace opening machine to hit the ladle, open the blast furnace iron mouth aperture, so that the iron flows smoothly out of the rock drilling tool, but also used for the use of gun holes, commonly used in drilling slightly hard rock formations, the applicable rock hardness range of f<12 grade. The four cutter wings of the cross-braze head are arranged diagonally, which can speed up the drilling process and improve the working efficiency. Under the condition of larger impact power rock drill, it drills cracked rock formation and abrasive rock formation with strong resistance to radial abrasion.

Rock drilling cross bits, also known as crosshead bits or cross-shaped drill bits, are specialized tools used in the drilling and excavation of rock formations. They are designed to withstand the extreme conditions encountered during rock drilling and are commonly used in mining, construction, and geotechnical engineering projects.

Cross bits typically have a conical shape with four raised carbide inserts arranged in a cross pattern. These inserts help to provide cutting edges and impact resistance, allowing the bit to effectively penetrate and break up the rock.

The design of rock drilling cross bits enables them to be used in various drilling methods, including rotary drilling and percussion drilling. They are commonly used with pneumatic or hydraulic rock drills and can be further adapted for specific rock formations and drilling conditions by selecting the appropriate carbide insert shapes and sizes.

When using rock drilling cross bits, it is essential to maintain proper drilling techniques and to ensure that the bits are correctly fitted and secured to the drilling equipment. Regular maintenance and sharpening of the carbide inserts are also recommended to ensure optimal performance and longevity.

In summary, rock drilling cross bits are specialized tools used for drilling and excavating rock formations in various industries. Their cross-shaped design and durable carbide inserts allow for effective rock penetration and breaking. Selecting the right cross bit for the specific drilling conditions is crucial for achieving efficient and successful drilling operations.

The1year

The1year

Thread Button Bit

Thread Button Bit

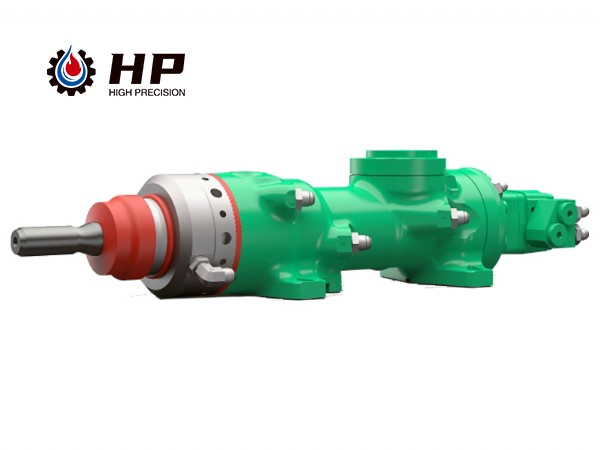

YT29 Air Leg Rock Drill

YT29 Air Leg Rock Drill

Bullet Teeth Bit

Bullet Teeth Bit

Steel Tooth Tricone Drill Bit

Steel Tooth Tricone Drill Bit

MF Drifter Rod

MF Drifter Rod

QL DTH Hammer

QL DTH Hammer

Mining Rock Drill Bits

Mining Rock Drill Bits

YYG100tr Hydraulic Rock Drill

YYG100tr Hydraulic Rock Drill

R32 Thread Button Bit

R32 Thread Button Bit