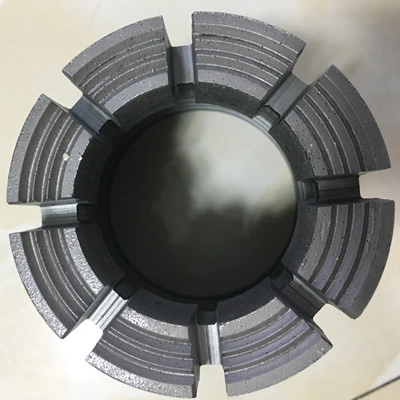

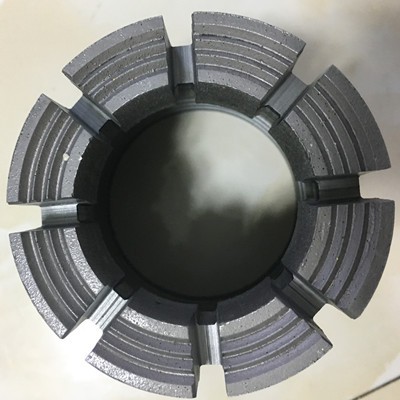

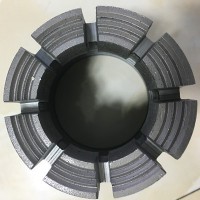

Impregnated Diamond Core Bits are crafted by blending small, top-notch synthetic diamonds uniformly within a metal matrix. These industrial-grade diamonds, ranging from fine to micro-fine quality, are meticulously placed within a matrix that spans a spectrum of hardness levels, from brass to high-grade steel.

The critical technical parameters of impregnated diamond core bits encompass diamond type, size, concentration, and grade, as well as matrix hardness and crown shapes. These parameters can be tailored to suit the specific rock formations being drilled. By making informed choices based on the geological conditions, drillers can achieve optimal drilling performance across a range of formations with varying degrees of hardness.

Key features of Diamond Core Bits for geological drilling include:

Diamond Impregnation: Small, high-quality synthetic diamonds are evenly distributed within the matrix material to ensure consistent and effective cutting action.

Matrix Hardness: The matrix material's hardness is carefully selected to withstand the abrasive forces encountered while drilling through various rock formations, ensuring durability and longevity of the core bit.

Diamond Type and Size: The type, size, concentration, and grade of diamonds used in the core bit impact cutting efficiency and wear resistance, allowing for optimal performance in different geological formations.

The1year

The1year

Bench Drill Rod

Bench Drill Rod

HP350 Water Well Drilling Rig

HP350 Water Well Drilling Rig

Button Drill Bit

Button Drill Bit

Y24 Jack Hammer

Y24 Jack Hammer

R32 Drifter Drill Rod

R32 Drifter Drill Rod

Thread Button Bit

Thread Button Bit

Dome Reaming Bit

Dome Reaming Bit

Plug Hole Drill Rod

Plug Hole Drill Rod

Impregnated Diamond Core Bits For

Impregnated Diamond Core Bits For

Taper Button Bit

Taper Button Bit