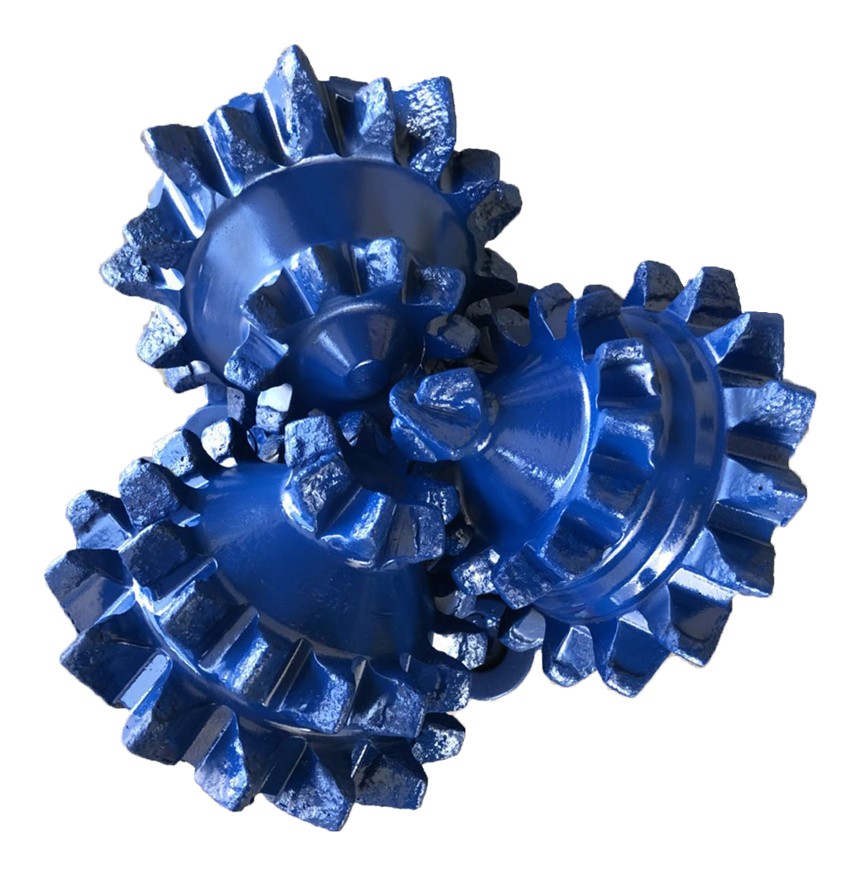

Highly Wear Resistant Spiral PDC Core Drills:

In the realm of mineral exploration and geological surveying, the quest for efficiency, precision, and durability in core drilling tools has always been paramount. The emergence of Highly Wear Resistant Spiral PDC (Polycrystalline Diamond Compact) Core Drills has marked a significant advancement in this field, offering a revolutionary solution to the challenges faced in deep drilling operations.

PDC core bits are specifically engineered to excel when paired with high-powered drill rigs that operate at lower rotation speeds. The unique design and composition of PDC core bits make them the ideal choice for deep drilling operations where longevity and penetration efficiency are crucial factors. In comparison to surface set bits, PDC core bits offer significantly enhanced bit life and penetration rates, making them a preferred option for demanding drilling applications.

One of the key advantages of using PDC core bits with high-powered drill rigs operating at lower rotation speeds is the improved overall performance and efficiency. The precise engineering of PDC core bits allows for optimal energy transfer from the drill rig to the cutting surface, resulting in more effective rock penetration and faster drilling progress. This efficiency is further amplified by the ability of PDC core bits to maintain their sharpness and cutting effectiveness over an extended period, leading to enhanced overall productivity and reduced downtime for bit changes.

In conclusion, the use of PDC core bits with high-powered drill rigs operating at lower rotation speeds offers a multitude of advantages over traditional surface set bits. From improved bit life and penetration rates to enhanced durability and stability, PDC core bits are a superior choice for deep drilling applications where efficiency, accuracy, and reliability are paramount. By leveraging the advanced technology and performance capabilities of PDC core bits, drilling operations can achieve higher productivity, reduced costs, and greater success in challenging geological environments.

The1year

The1year

Bullet Teeth Bit

Bullet Teeth Bit

HC25 HC28 HC109 Piston

HC25 HC28 HC109 Piston

Spare Parts For Road Milling Mach

Spare Parts For Road Milling Mach

High Quality Coal Mining Bits

High Quality Coal Mining Bits

High Air Pressure DTH Drill Bits

High Air Pressure DTH Drill Bits

Small Hole Drill Tools

Small Hole Drill Tools

Tapered Chisel Bit

Tapered Chisel Bit

Rock Solid Precision DTH Bits

Rock Solid Precision DTH Bits

R32 Thread Coupling Sleeve

R32 Thread Coupling Sleeve

QL DTH Hammer

QL DTH Hammer