1. Flat-shaped teeth: Unlike conical or bullet-shaped teeth, flat teeth have a broad, flat surface that enables them to effectively cut through soil or rock with less resistance. This design allows for increased stability and control during the drilling process.

2. Versatility: Flat teeth can be used for drilling in various soil and rock conditions, including cohesive soils, hard clays, soft rocks, and weathered rock formations.This versatility makes them suitable for a wide range of foundation drilling applications.

3. Durability: Flat teeth are typically made from strong and durable materials such as hardened steel or tungsten carbide. This ensures that they can withstand the high impact and abrasion forces encountered during drilling, resulting in longer-lasting cutting tools.

4. Easy replacement: When flat teeth become dull or worn out, they can easily be replaced by detaching the old teeth and attaching new ones. This allows for quick maintenance and reduces downtime on the drilling site.

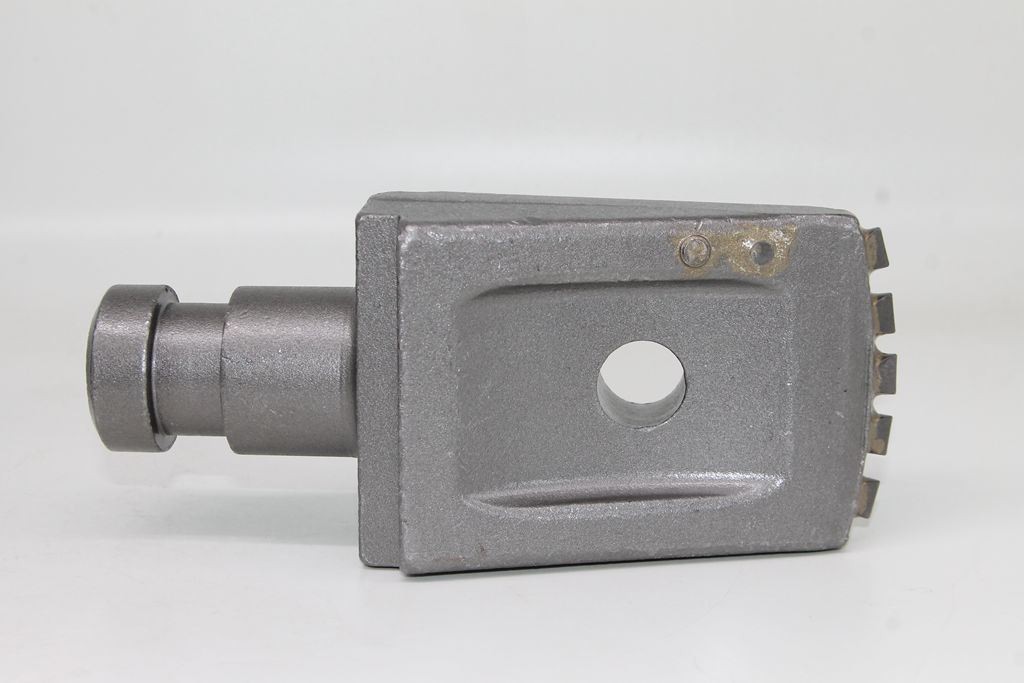

Flat teeth foundation drilling refers to a method of drilling foundations using a drilling rig equipped with flat teeth or cutting tools. These flat teeth are designed to efficiently cut through different types of soil and rock formations, allowing for the construction of stable foundations for structures such as buildings, bridges, and dams.

The key features of flat teeth foundation drilling include:

1. Flat-shaped teeth: Unlike conical or bullet-shaped teeth, flat teeth have a broad, flat surface that enables them to effectively cut through soil or rock with less resistance. This design allows for increased stability and control during the drilling process.

2. Versatility: Flat teeth can be used for drilling in various soil and rock conditions, including cohesive soils, hard clays, soft rocks, and weathered rock formations. This versatility makes them suitable for a wide range of foundation drilling applications.

3. Durability: Flat teeth are typically made from strong and durable materials such as hardened steel or tungsten carbide. This ensures that they can withstand the high impact and abrasion forces encountered during drilling, resulting in longer-lasting cutting tools.

4. Easy replacement: When flat teeth become dull or worn out, they can easily be replaced by detaching the old teeth and attaching new ones. This allows for quick maintenance and reduces downtime on the drilling site.

5. Cost-effective: Flat teeth foundation drilling is a cost-effective method compared to other drilling techniques. The flat teeth provide efficient cutting performance, minimizing energy consumption and reducing the overall drilling costs.

In summary, flat teeth foundation drilling offers a reliable and efficient method for drilling foundations in various soil and rock conditions. The flat-shaped teeth provide stability, versatility, and durability, making them a popular choice for constructing stable and strong foundations.

The1year

The1year

HP800 Water Well Drilling Rig

HP800 Water Well Drilling Rig

11 Degree Taper Drill Rod

11 Degree Taper Drill Rod

Trenchers Flat Tooth Foundation D

Trenchers Flat Tooth Foundation D

Y19A Jack Hammer

Y19A Jack Hammer

112mm PDC Core Drill Bit for Well

112mm PDC Core Drill Bit for Well

T45 Guide Tube

T45 Guide Tube

T45 Thread Coupling Sleeve

T45 Thread Coupling Sleeve

Wear Parts Flat Tooth Foundation

Wear Parts Flat Tooth Foundation

High Air Pressure DTH Hammer

High Air Pressure DTH Hammer

HP350 Water Well Drilling Rig

HP350 Water Well Drilling Rig