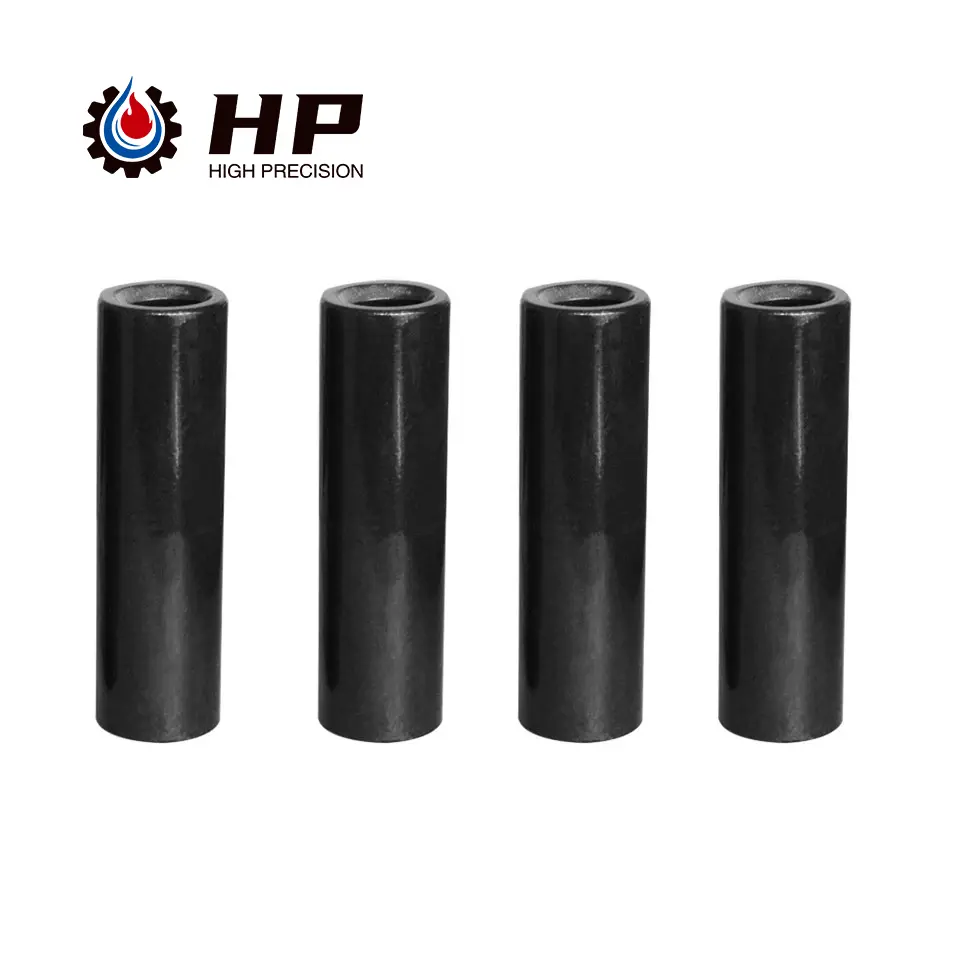

R32 Threaded Connection Sleeves are made from a high quality alloy steel material, which has excellent strength and durability and is capable of withstanding high-intensity torque transfer and connection operations. The alloy steel material also has good abrasion resistance and deformation resistance, and is able to maintain stable performance in harsh geotechnical environments.

R32 Threaded Connection Sleeves are precision machined to ensure that they are dimensionally accurate and have a smooth surface to provide a solid and reliable connection. Precision machining also helps to reduce friction and wear between components, extending the service life of the connecting sleeve and ensuring its long-term stable working performance.

The connecting sleeve undergoes a specialized heat treatment process to enhance the strength and hardness of its material and improve its resistance to fatigue and deformation. This heat treatment process can also improve the internal structure of the material, improve its overall performance, to ensure that it can withstand complex mechanical stresses in high-intensity geotechnical engineering drilling operations.

Overall, the material selection, precision machining and heat treatment of R32 threaded connecting sleeves are designed to ensure that they have sufficient strength and durability to meet the high intensity demands of geotechnical drilling operations, providing reliable connections and torque transmission for drilling operations.

The1year

The1year

Ultra Rock Precision DTH Bits

Ultra Rock Precision DTH Bits

YT28 Air Leg Rock Drill

YT28 Air Leg Rock Drill

Pilot Reaming Bit

Pilot Reaming Bit

T38 MF Rod

T38 MF Rod

T51 MF Rod

T51 MF Rod

Coal Mining Drill Bits

Coal Mining Drill Bits

Hyundai Excavator Bucket Tooth Ho

Hyundai Excavator Bucket Tooth Ho

Rock Solid Precision DTH Bits

Rock Solid Precision DTH Bits

QL DTH Bit

QL DTH Bit

Carbide Rotary Digging Teeth

Carbide Rotary Digging Teeth