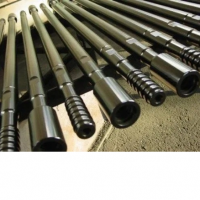

Precision Drill Rods are manufactured from high-strength alloy steel, a material with excellent strength and durability that can withstand the stresses of high pressure and heavy-duty working conditions, ensuring that they are not easily deformed or damaged during the drilling process.

The drill rod is connected with the drill rod by taper and the drill rod by thread, and the drill bit connected with the drill rod can be replaced with different types and specifications for use with rock drills and trolleys.

Tapered drill rods, also known as tapered drill rods, finished drill rods, small drill rods and pneumatic drill rods, are driven by small pneumatic rock drills or hydraulic rock drills to carry out shallow hole drilling operations with tapered drill heads. Commonly used products are H22 and H25 specifications, and taper drill rods are commonly used with taper, and the product length is 400mm-5000mm.

Threaded drill rod is also called threaded drill rod, hydraulic drill rod, hydraulic drill rod, heavy drill rod and heavy drill rod. Threaded drill rod is a kind of rock drilling tool which is connected with drill bit, hydraulic rock drill and threaded drill bit, and transfers the impact work and rotary toggle force of hydraulic rock drill to the threaded drill bit to break rocks. This kind of drilling tool is generally used with hydraulic drilling jumbo and hydraulic drilling rig. The main thread forms are R22, R25, R28, R32, TR35, T38, T45, T51, ST58, ST68, T60, EL60 and EL68 threaded drill rods, which are divided into quick-change drill rods (MF drill rods) and extension drill rods. .

One-piece brazing is different from the ordinary drill rod with replaceable drill bit. Because the drill rod and drill bit are integrated, it cannot be replaced. The connecting rod is not long enough and is used as an extension.

The1year

The1year

R32 Thread Coupling Sleeve

R32 Thread Coupling Sleeve

R32 Thread Button Bit

R32 Thread Button Bit

HP680 Water Well Drilling Rig

HP680 Water Well Drilling Rig

Crawler Core Drilling Machine Min

Crawler Core Drilling Machine Min

Tapered Chisel Bit

Tapered Chisel Bit

Pneumatic Rock Drill Accessories

Pneumatic Rock Drill Accessories

7 Degree Button Bit

7 Degree Button Bit

Plug Hole Drill Rod

Plug Hole Drill Rod

T45 Thread Shanks Adapter

T45 Thread Shanks Adapter

Taper Rock Drill Rod

Taper Rock Drill Rod