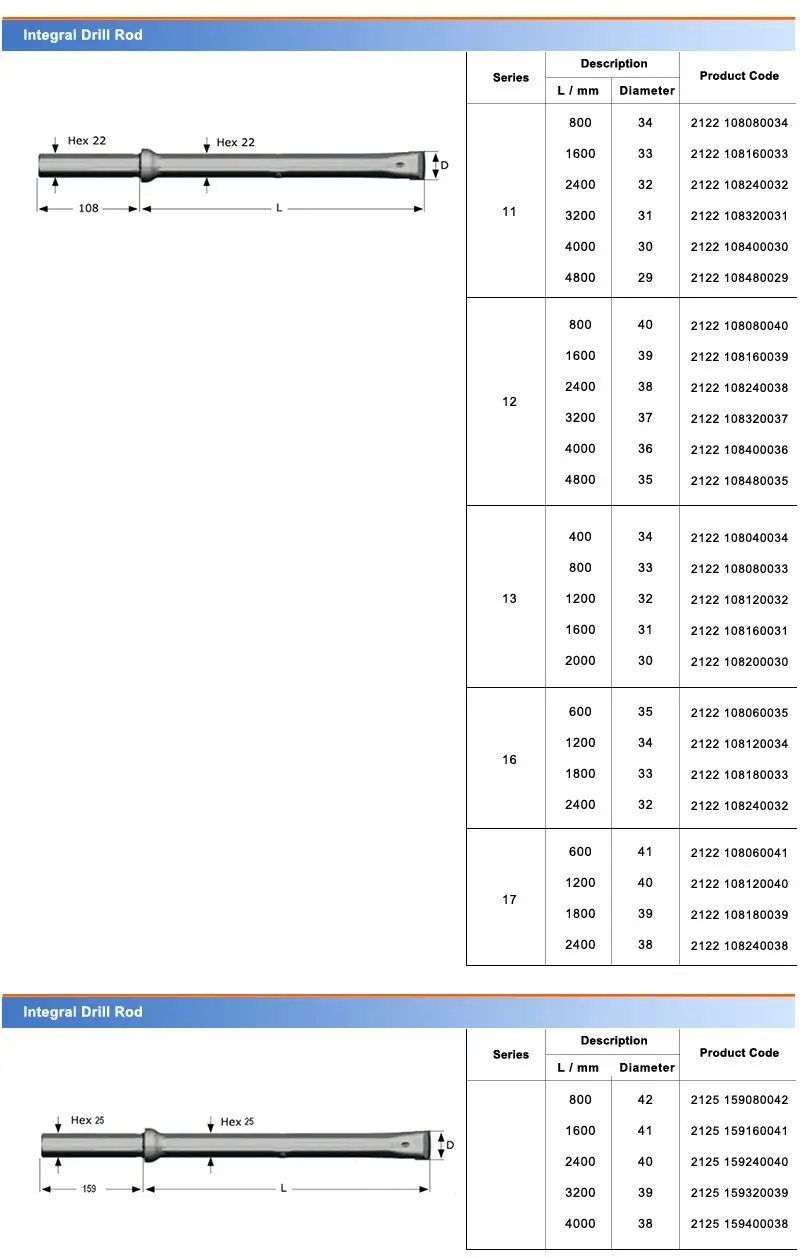

Integral drill pipe plays an important role in rock drilling field with its excellent design features and many advantages. It not only improves drilling efficiency and accuracy, but also reduces maintenance costs, providing solid and reliable technical support for rock drilling operations.

Design Features

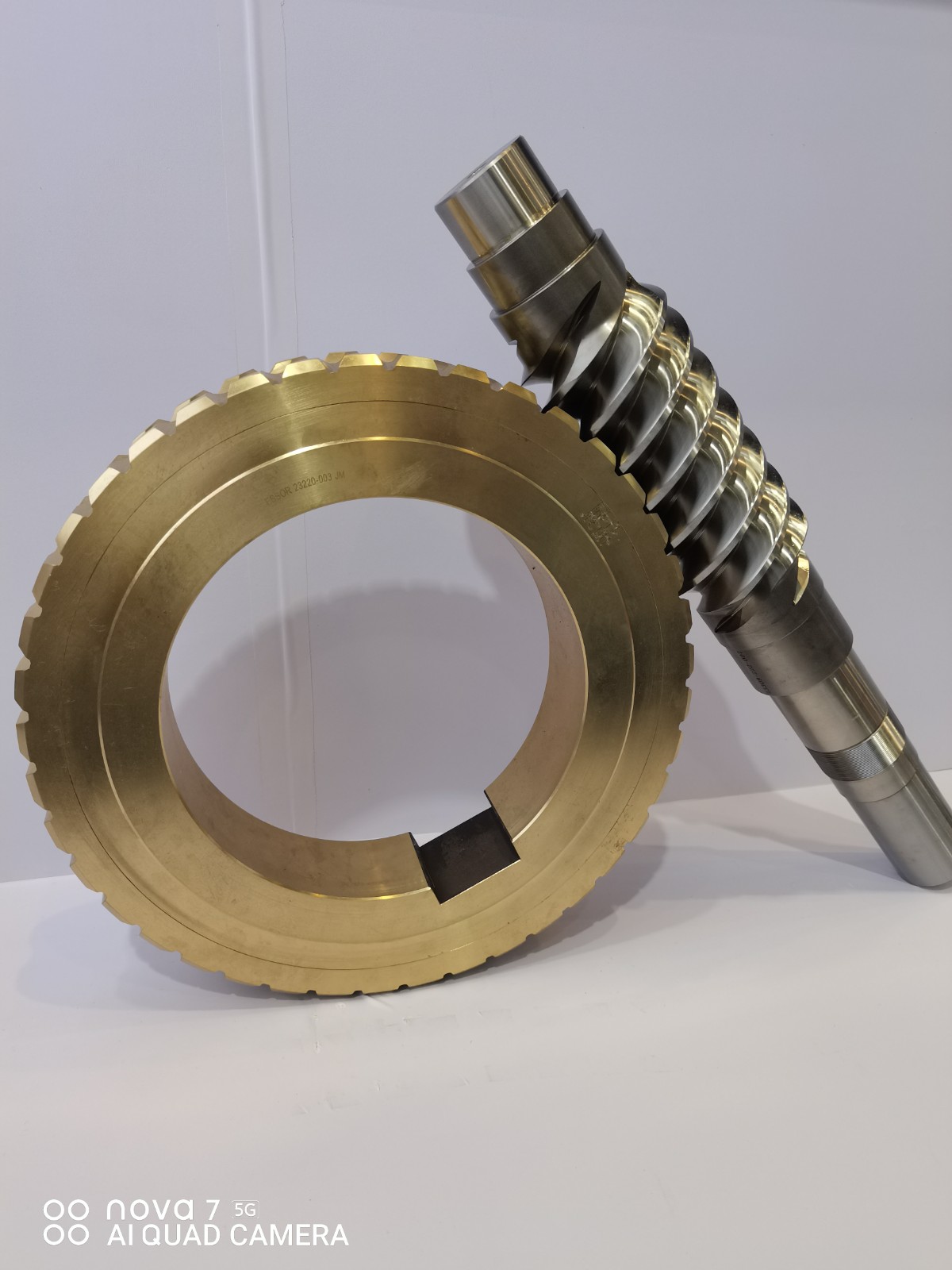

Integral Drill Pipe is a one-piece forged drilling tool, and its design features include:

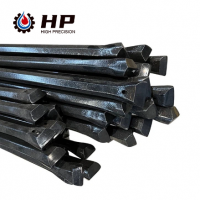

Integral structure: Integral drill pipe adopts one-piece molding design, which eliminates the weakness of joint part and improves the overall strength and durability.

High-quality alloy steel: Made of high-quality alloy steel with excellent abrasion resistance and bending strength, it is able to cope with complex rock formations.

Threaded connection: the two ends of the overall drill pipe are threaded, which is easy to connect with the drill bit and drill pipe to ensure solid transmission of drilling power.

Integral drill pipe has many advantages in rock drilling operations:

Improved drilling efficiency: the design and material of the integral drill pipe enables it to transmit drilling power quickly and stably, which improves drilling efficiency and reduces operation time.

Reduced maintenance costs: Due to the more robust structure of the integral drill pipe, the cost of use and maintenance is relatively low, reducing the need for frequent replacement of drilling tools.

Accurate drilling position: The stability of the integral drill pipe and the precise transmission of drilling force can ensure the accuracy of the drilling position and improve the precision of rock drilling.

The1year

The1year

T38 Thread Shank Adapter

T38 Thread Shank Adapter

Popular Precision DTH Bits

Popular Precision DTH Bits

Taper Drill Rod

Taper Drill Rod

QL DTH Hammer

QL DTH Hammer

DHD DTH Hammer

DHD DTH Hammer

Pneumatic Rock Drill Accessories

Pneumatic Rock Drill Accessories

HP500 Water Well Drilling Rig

HP500 Water Well Drilling Rig

Low Air Pressure DTH Drill Bits

Low Air Pressure DTH Drill Bits

Mining Rock Drill Bits

Mining Rock Drill Bits

R25 45mm Thread Button Bit

R25 45mm Thread Button Bit