Extension drill rods, also known as extension drill steel, steel bars, or extension bars, are available in hexagonal and round cross-sections. Hexagonal rods offer increased rigidity, weight, and energy transfer efficiency, leading to improved flushing. On the other hand, round rods are generally lighter and are commonly used in extension drilling applications. Longer extension rods tend to have larger diameters. Conventional extension steel is characterized by duplicate threads on each end of the steel.

Extension drill rods are manufactured from hollow drill steels, offering a range of lengths from 600mm to 6400mm. The hollow hole within the rods, often referred to as the flushing hole, is utilized for the transmission of water or air during drilling operations. Additionally, the threaded ends of the rods are designed for connecting couplings, shank adapters, or drill bits, facilitating the assembly of the drilling equipment.

Fully carburization is a critical process utilized to harden the entire surface of the rod, both internally and externally. This process serves to strengthen the rod and extend its operational life, ensuring durability and reliability in demanding drilling environments.

Overall, extension drill rods play a crucial role in various drilling applications, offering versatility, durability, and efficient energy transfer. Their design and construction contribute to the effectiveness and longevity of drilling operations, making them essential components in the field of rock drilling and excavation.

The1year

The1year

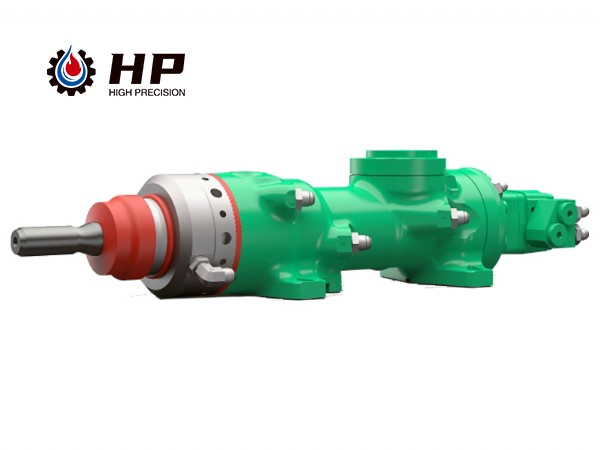

HP680 Water Well Drilling Rig

HP680 Water Well Drilling Rig

High Air Pressure DTH Drill Bits

High Air Pressure DTH Drill Bits

Pilot Reaming Bit

Pilot Reaming Bit

Tapered Tungsten Carbide Button B

Tapered Tungsten Carbide Button B

Wear Parts Flat Tooth Foundation

Wear Parts Flat Tooth Foundation

Drill Rod Forging Machine

Drill Rod Forging Machine

T51 Guide Tube

T51 Guide Tube

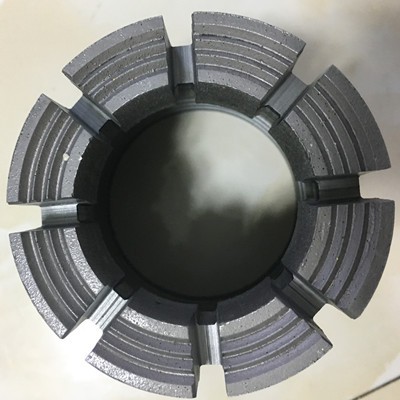

Thread Button Bit

Thread Button Bit

Small Hole Drill Tools

Small Hole Drill Tools

T45 Thread Coupling Sleeve

T45 Thread Coupling Sleeve