Mining rock drill bits are precision-engineered tools that are specifically designed to handle the challenging conditions of mining operations. These bits are crafted from high-quality materials such as tungsten carbide, making them durable and resistant to wear and tear. Their robust construction enables them to withstand the extreme pressure and heat encountered during drilling, ensuring consistent performance even in the harshest of environments.

The various shapes and types of mining rock drill bits cater to different needs and requirements in the mining industry. For example, cross-type bits are ideal for drilling in hard rock formations, while button bits are effective in softer ground conditions. This diversity in design allows miners to select the most suitable drill bit for each specific task, optimizing efficiency and productivity in the extraction process.

The precise drilling capabilities of rock drill bits contribute to the accuracy and reliability of mining operations. By creating clean and well-defined boreholes, these bits facilitate the extraction of minerals with minimal waste and maximized output. This level of precision is essential for ensuring the economic viability of mining projects, as it directly impacts the quality and quantity of the mineral reserves recovered.

Adaptability is another key advantage of mining rock drill bits. These versatile tools can be customized and configured to meet the unique requirements of different mining sites and geological conditions. Whether it is for surface mining or underground operations, drill bits can be tailored to deliver optimal performance, making them indispensable assets in the mining industry.

The1year

The1year

Power DTH Bits

Power DTH Bits

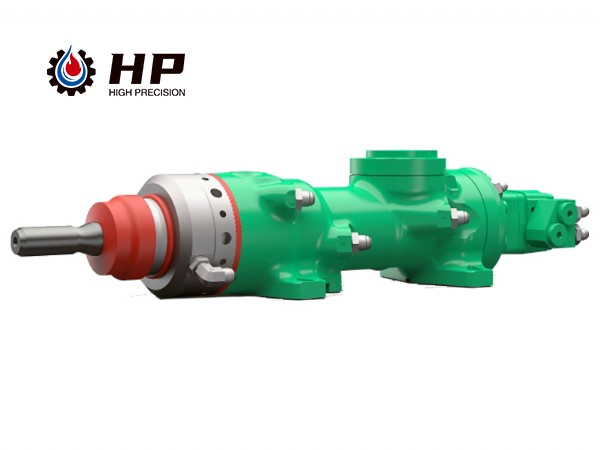

YYG100tr Hydraulic Rock Drill

YYG100tr Hydraulic Rock Drill

HC50 HC95 HC109 Holding Sleeve Th

HC50 HC95 HC109 Holding Sleeve Th

DTH Hammer 4 Inch

DTH Hammer 4 Inch

Long Skirt Taper Button Bit

Long Skirt Taper Button Bit

Drill Rod Forging Machine

Drill Rod Forging Machine

GT60 Thread Button Bit

GT60 Thread Button Bit

New Water Well Drill Pipe

New Water Well Drill Pipe

YT28 Air Leg Rock Drill

YT28 Air Leg Rock Drill

High Air Pressure DTH Drill Bits

High Air Pressure DTH Drill Bits