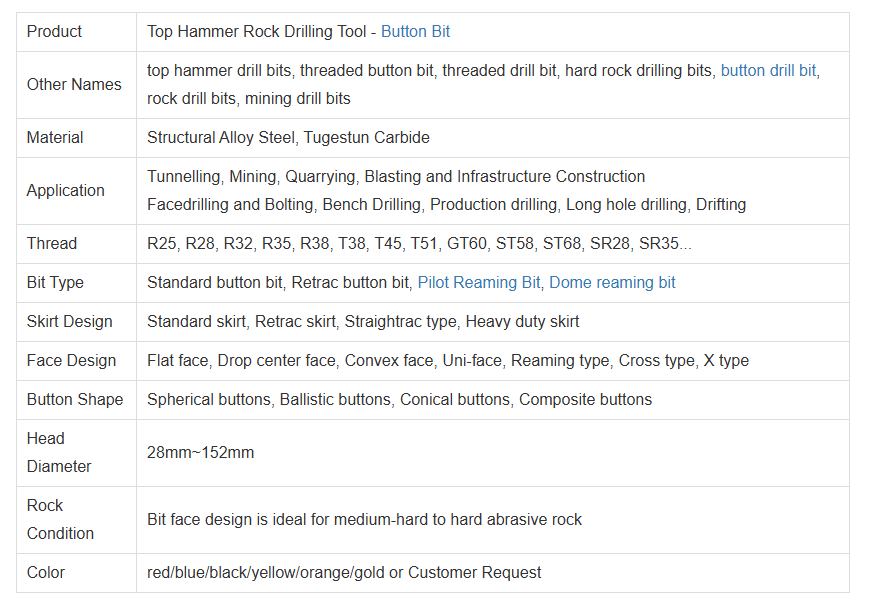

The tungsten carbide material used for the carbide buttons is known for its durability and wear resistance, making the top hammer buttons bit a long-lasting and cost-effective drilling tool. This ensures that the bit can withstand the high levels of impact and abrasion encountered during drilling operations, resulting in reduced downtime and maintenance costs.

The top hammer buttons bit is designed to provide efficient and effective drilling in challenging conditions. The carbide buttons are strategically placed on the bit body to ensure maximum impact and penetration when drilling through hard rock formations. This design helps to increase the speed and accuracy of the drilling process, ultimately improving productivity on mining and construction sites.

The shank of the top hammer buttons bit is designed to connect the drill bit to the drilling rig, providing stability and control during the drilling process. This allows for precise positioning and alignment of the bit, ensuring accurate drilling and minimizing the risk of deviation or errors in the drilling trajectory.

The1year

The1year

Y24 Jack Hammer

Y24 Jack Hammer

New Steel Tooth Tricone Bit

New Steel Tooth Tricone Bit

Good Quality Core Drilling Machin

Good Quality Core Drilling Machin

HC25 HC28 Holding Sleeve Thrust S

HC25 HC28 Holding Sleeve Thrust S

Hot Sale Rock Bullet Teeth

Hot Sale Rock Bullet Teeth

YT28 Air Leg Rock Drill

YT28 Air Leg Rock Drill

DTH Bits

DTH Bits

Bullet Teeth Holder

Bullet Teeth Holder

Taper Drill Tools

Taper Drill Tools