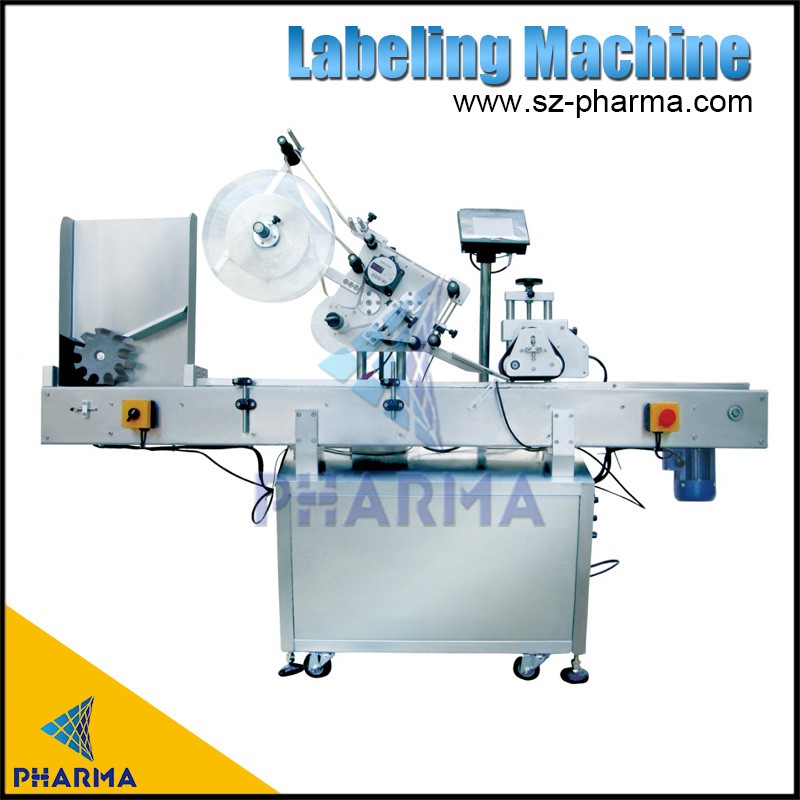

- Product name:

- Labeling Machine For Bottles

- Max label size:

- 360mm*60mm

- Conveying direction:

- left-right; right-left

![]()

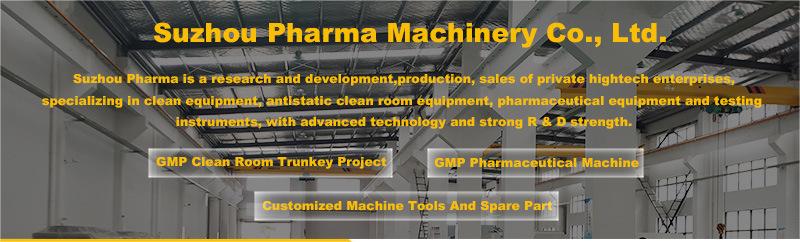

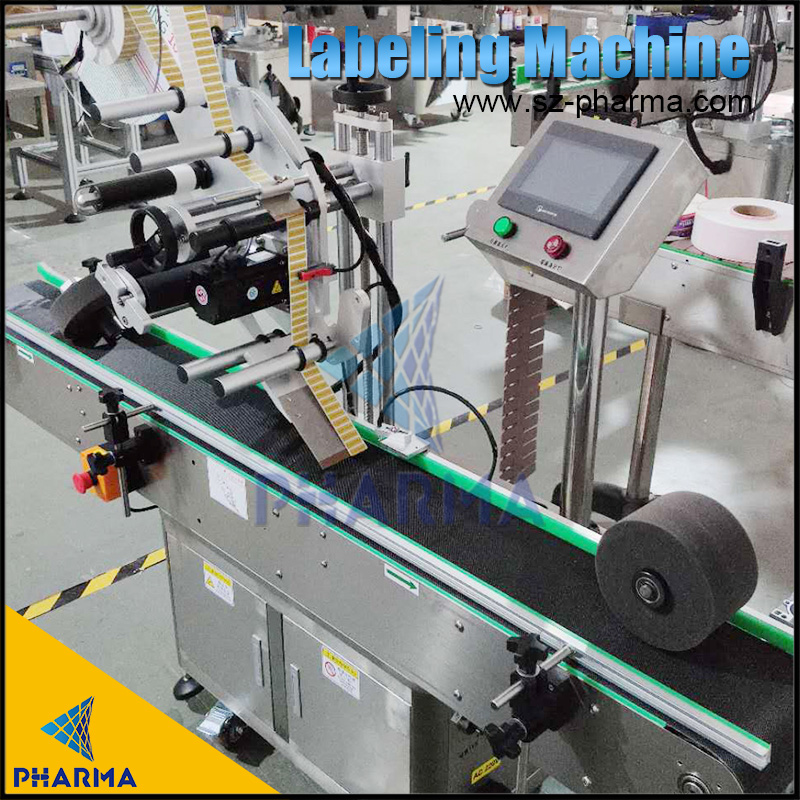

Characteristics

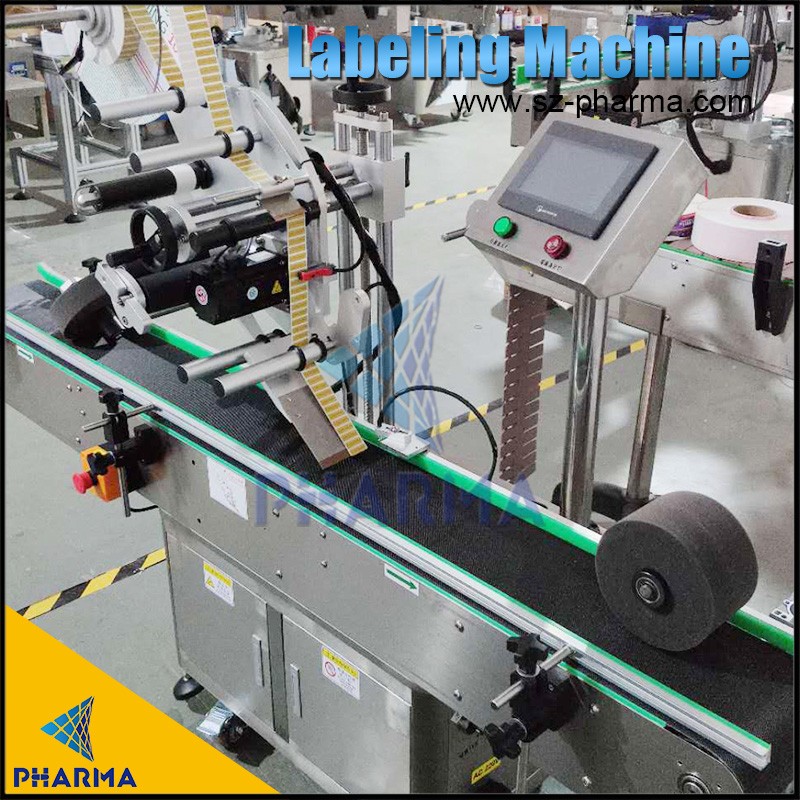

◆Using a new type of elastic pressure topping mechanism to ensure stable product delivery and

effectively eliminate the inherent error of bottle height;

◆The labeling is accurate and stable. It adopts PLC+subdivision stepping motor to drive the label delivery,

and the label delivery is accurate; the cam brake mechanism is adopted to ensure uniform tension to ensure

the tension of the label, reduce label breakage, and ensure accurate label detection; With detour correction

mechanism, it can prevent the label from shifting left and right, and ensure the accuracy of the label;

◆Powerful functions, color touch screen control, Chinese and English optional operation interface,

convenient and intuitive, powerful data memory function, can store 50 sets of labeling parameters, production

counting function, power saving function, production number setting prompt function, parameter setting

protection Function, convenient for production management, one-click switching of labeling for different

products, no need to repeatedly debug, simple and fast; and has a complete fault prompt and help function.

Applicable product range | Diameter: 20-150mm Height: 10-350mm |

Applicable label range | Height: 15-180 mm Length: 10-250mm |

Operating power(kw) | 0.18 |

Machine Model | SH-300 |

Drum Diameter | 300mm |

Max material load capacity | 20-30 lbs |

Max Rotating Speed | 1400r/min |

Motor Power | 1kw |

Machine weight | 300kg |

Machine Dimension | 580*550*600mm |

The1year

The1year

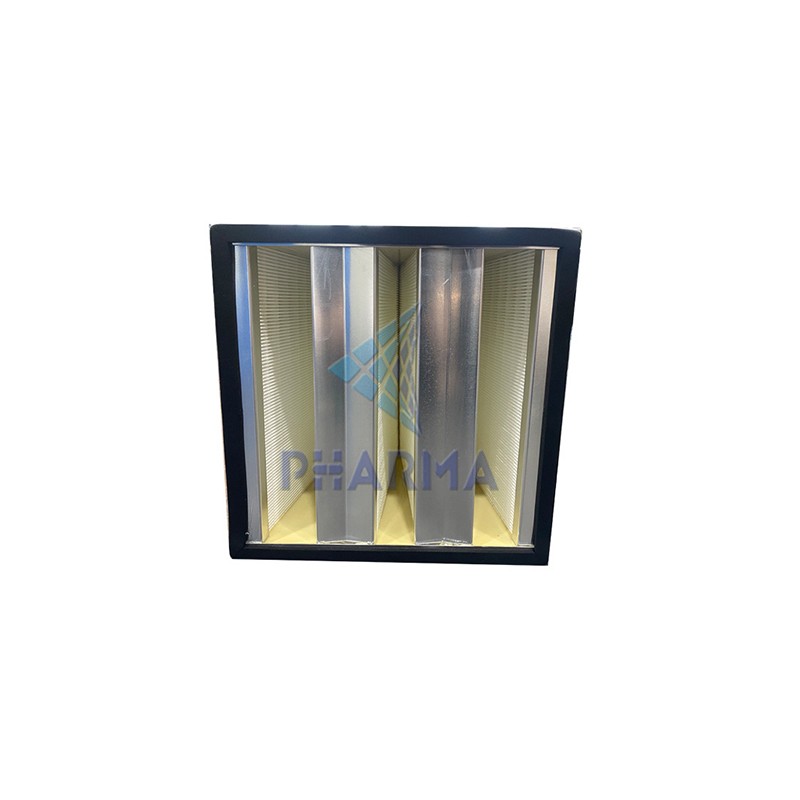

H12, H13 HEPA Filter

H12, H13 HEPA Filter

Vial Filling Machine 2023

Vial Filling Machine 2023

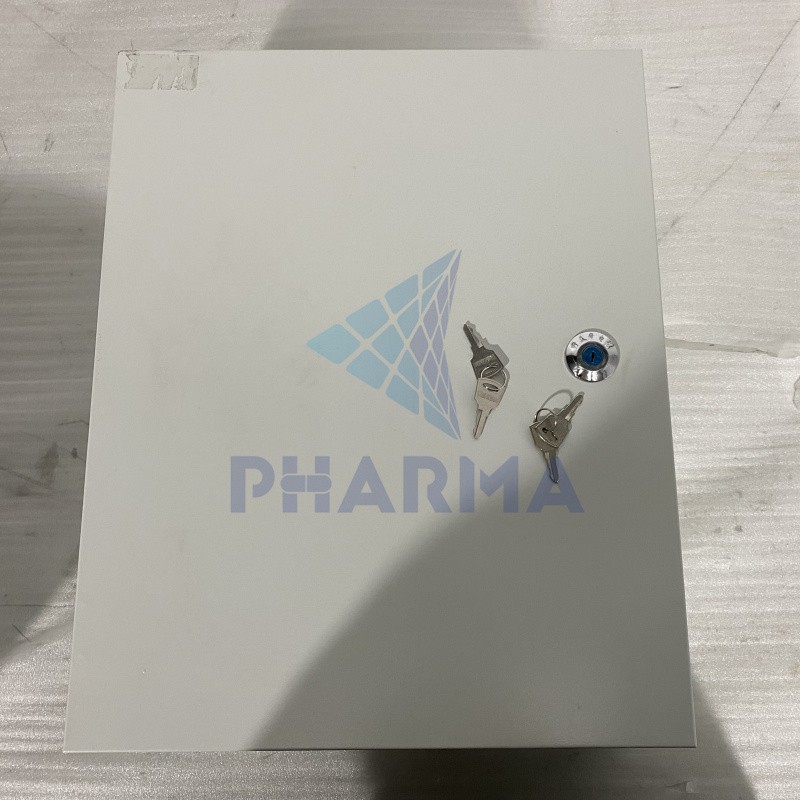

electrical distribution box

electrical distribution box

Power Control Cabinet

Power Control Cabinet

Air Filter For Air Conditioner

Air Filter For Air Conditioner

Cheap Price Air Condition HVAC

Cheap Price Air Condition HVAC

Dust-free Room PVC Floor

Dust-free Room PVC Floor

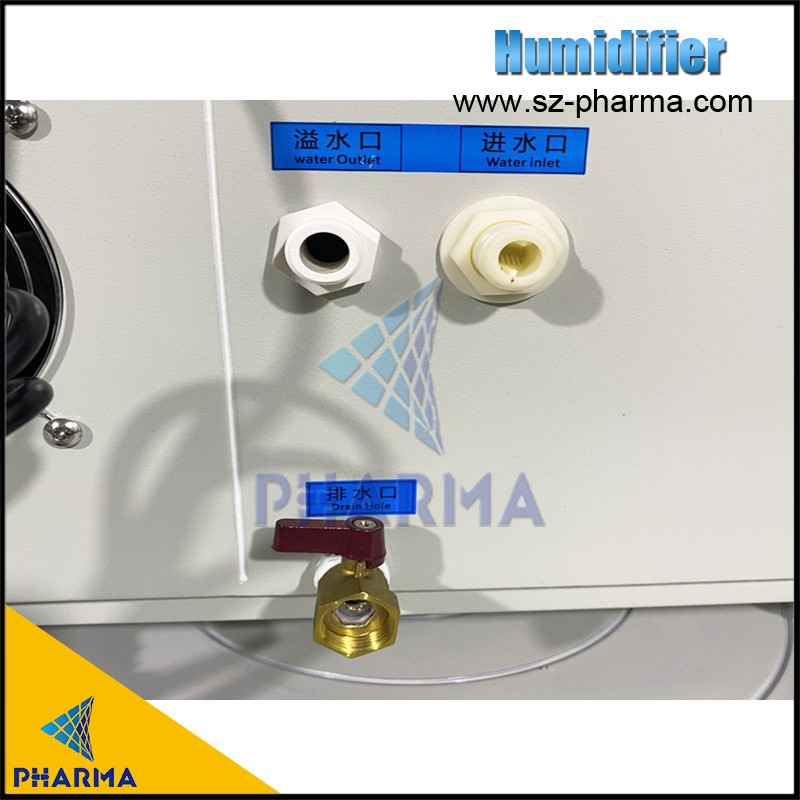

Large Capacity Humidifier

Large Capacity Humidifier

Energy Saving LED Lamp

Energy Saving LED Lamp

New Ultrasonic Humidifier

New Ultrasonic Humidifier