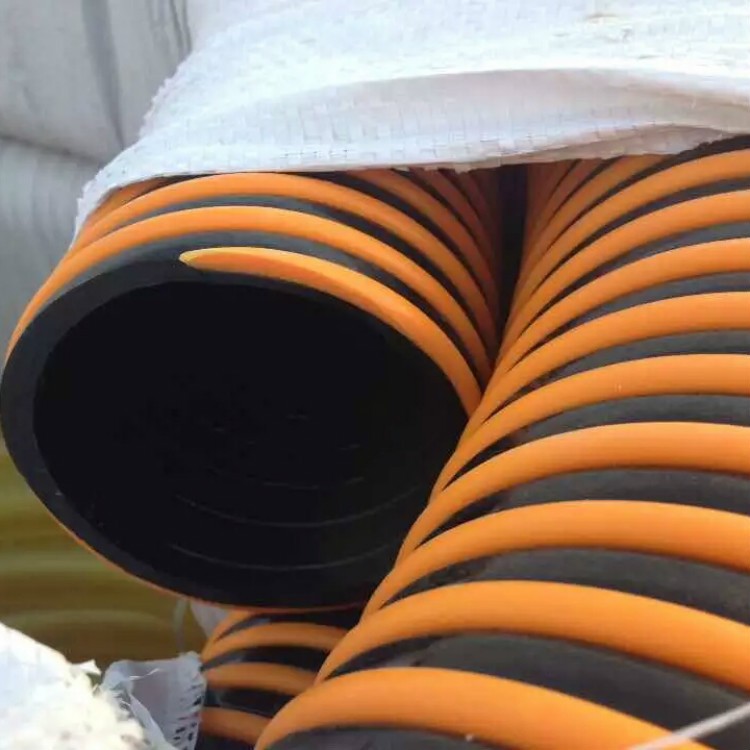

Composite Hose

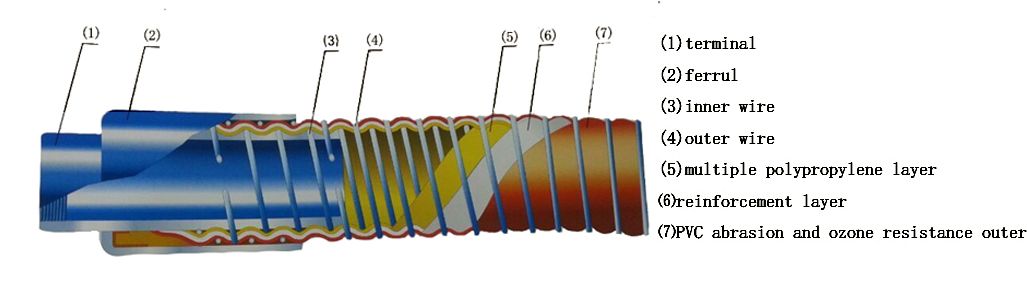

Our composite hose can handle chemical and cryogenic fluids. Utilizing multiple tight-wound component layers that create a very long and complex course for fluids. The unique process assures the proper gauge and pitch of the inner and outer wires at all times. Our composite hose is rated for both positive pressure and full vacuum. Besides, it will not kink and it’s easy to operate. In a word, it has long service life and great property.

All of our mandrel composite hoses are built with many multiple wraps of both polar and nonpolar films that contain the fluids and vapors inside the hose wall. The barrier layer in all our standard oil and chemical hoses prevents permeation by both polar fluids (like methanol) and non-polar liquids (like gasoline) from escaping the hose. The hose wall is then reinforced with bulk woven fabrics that help protect the films in the hose wall from mechanical damage. This provides you a composite hose with superb structure and heavy duty cover layers. While they do not deteriorate due to ozone, UV, oil or chemical attack. Besides, it’s flexible and durable with high strength.

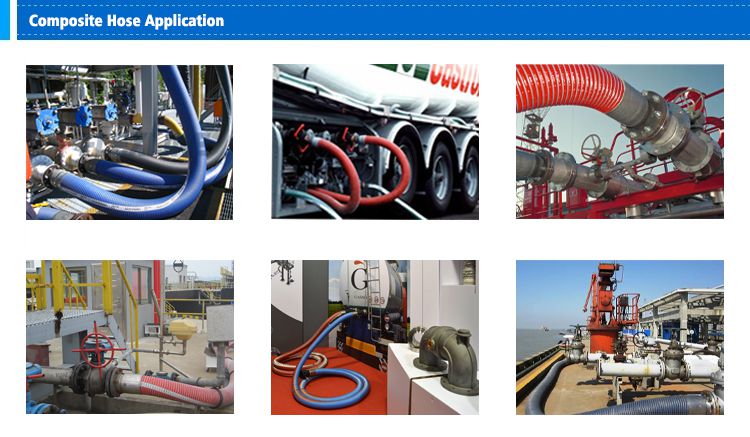

Application:

Composite hose provides the vital flexible connection to compensate vibration and movement in a fluid transfer system. It can also deliver fuels, oils and lubricants on tank trucks, railcars or fixed deposits.

Characteristic:

● 40% lighter than the rubber hose which has the same diameter and length.

● Flexible, good positive and negative pressure resistance

● Excellent corrosion resistance for chemical liquid medium

● Flame retardant

● Anti-static, long-term durable

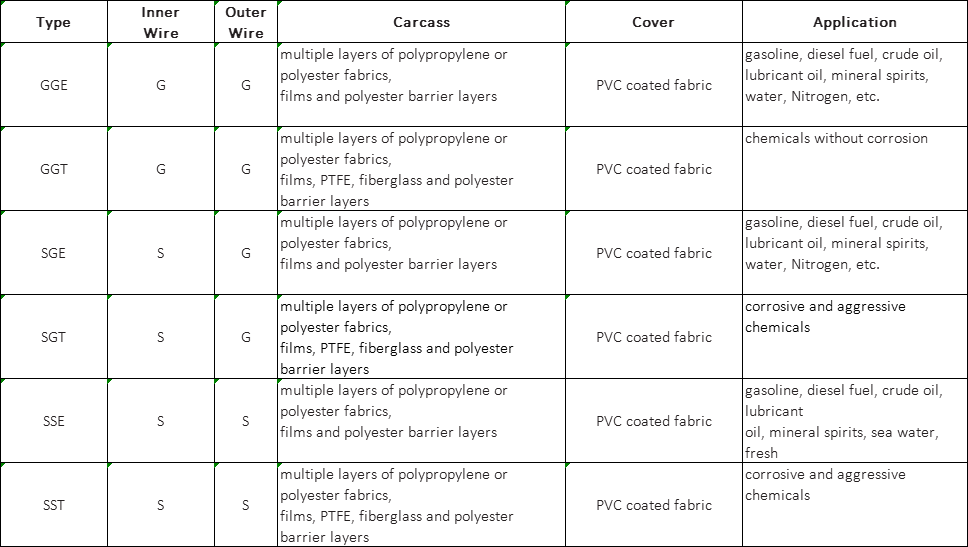

Note: Three capital letters are used for the composite hose. The first capital letter means the inner wire; the second capital letter

means the outer wire; the third letter means the carcass.

S—stainless steel 304/304L/316/316L G—galvanized steel E—Polypropylene T— PTFE

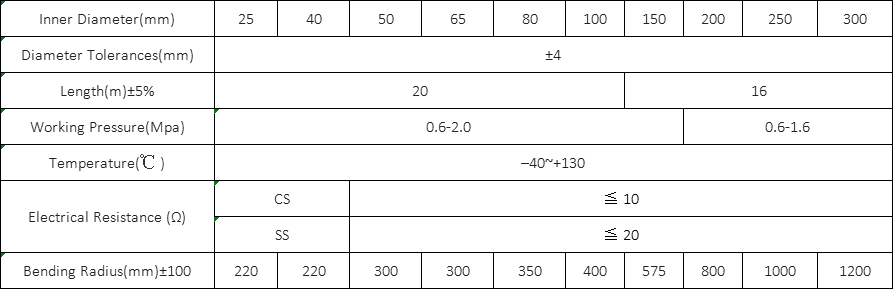

Specification:

Note: 1. The max diameter of the camlock can reach 150(6”), other spes are on your demand.

2. The outer diameter changes with the inner diameter.

The1year

The1year

medium and low pressure hose

medium and low pressure hose

Oven sealing strip

Oven sealing strip

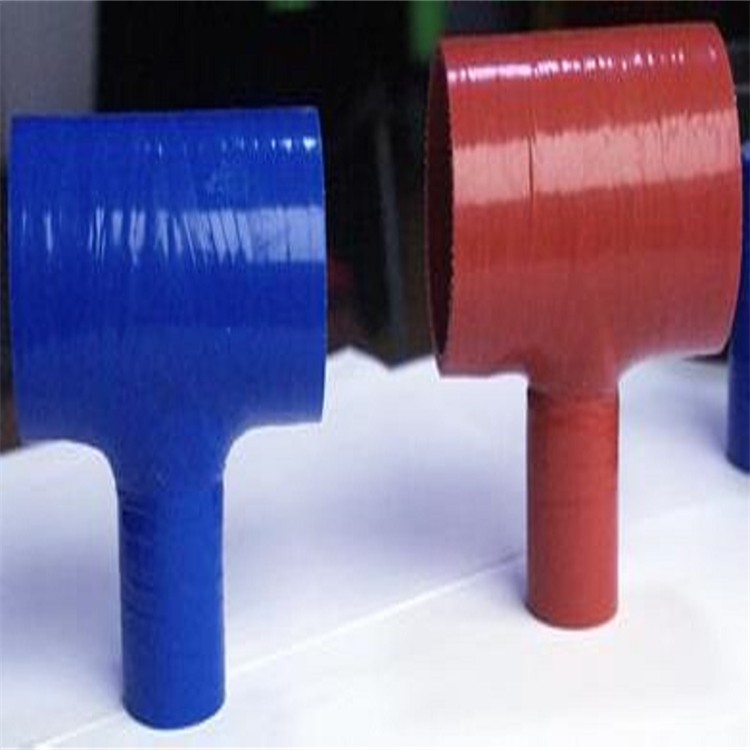

Silicone Vacuum Hose

Silicone Vacuum Hose

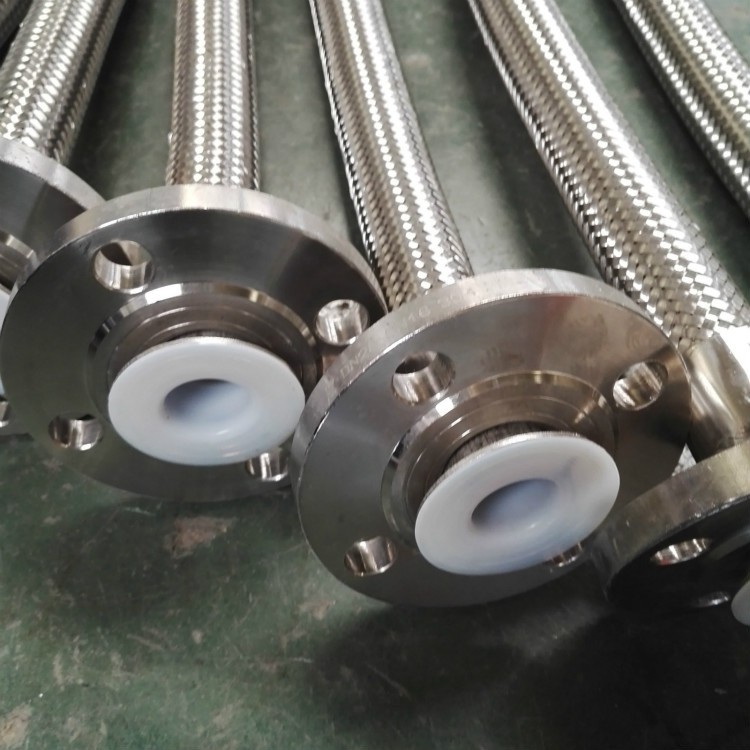

flexible metal hose

flexible metal hose

PVC pipette

PVC pipette

PTFE lined hose

PTFE lined hose

Silicone sealing strip

Silicone sealing strip

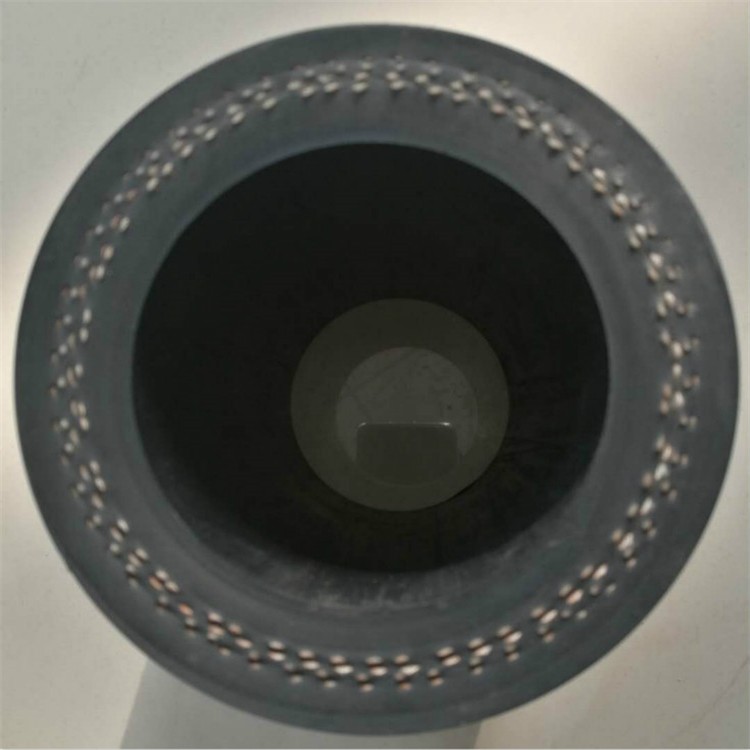

Peristaltic Pump Hose

Peristaltic Pump Hose

Hydraulic rubber hose EN8564SH

Hydraulic rubber hose EN8564SH