1、 Product structure:

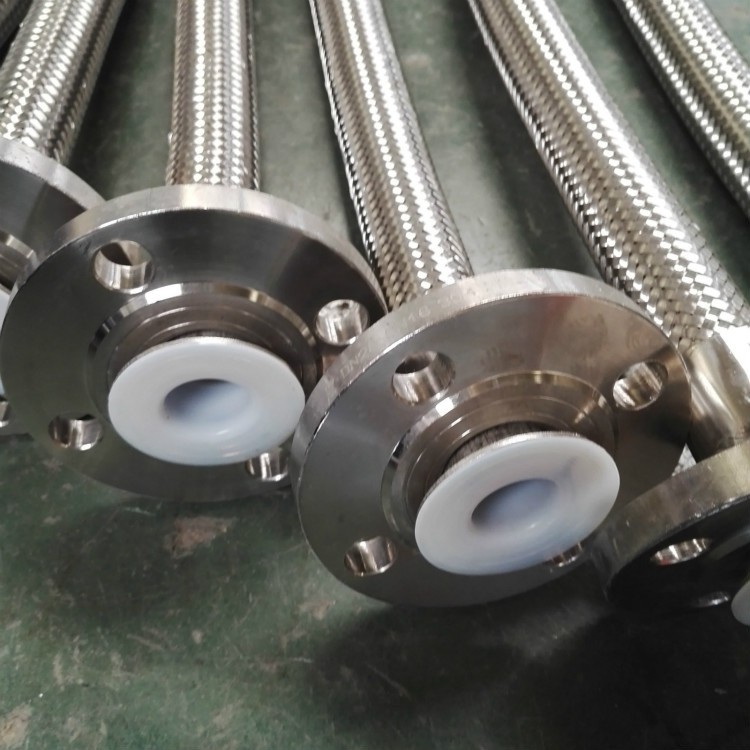

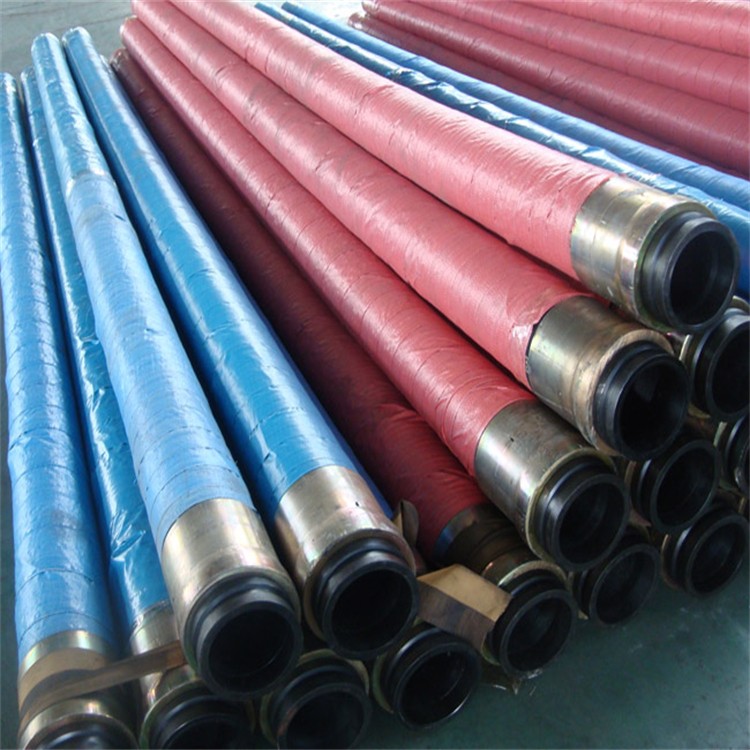

The structure of the steel wire braided rubber hose is composed of the inner rubber layer of the liquid-resistant synthetic rubber, the middle rubber layer, the I or II or III steel wire braided reinforcement layer, and the outer rubber layer of the weather-resistant synthetic rubber.

2、 Product use:

Steel wire reinforced hydraulic hose is mainly used for mine hydraulic support and oil field exploitation, and is applicable to the transportation of petroleum dam se (such as mineral oil, soluble oil, hydraulic oil, fuel oil, lubricating oil) engineering construction, lifting and transportation, liquid metallurgy forging with certain pressure and temperature in mechanical equipment, mining equipment, ships, injection molding machinery, agricultural machinery, various machine tools, and mechanization of various industrial departments The automatic hydraulic system dam transports liquid (such as emulsion, oil-water emulsion, water), gas, etc. and liquid.

3、 Operating temperature:

Oil: - 40 ℃ -+100 ℃, air: - 30 ℃ -+50 ℃, water: below+80 ℃. If the temperature is higher than 80 ℃, please use our special products.

4、 Product features:

1. The rubber hose is made of special synthetic rubber with excellent oil resistance, heat resistance and aging resistance.

2. The rubber hose has high pressure and excellent pulse performance.

3. The tube body is tightly combined, soft to use, and small compression deformation.

4. The rubber hose has excellent bending and fatigue resistance.

5. The length of steel wire braided hose is large, and the maximum length can reach tens of meters, or even more than 100 meters.

一层钢丝编织胶管技术参数

| 软管规格 | 内径 | 钢丝层直径 | 外径 | 工作压力 | 试验压力 | 爆破压力 | 最小弯曲半径 | 参考重量 | |||

MPA | Psi | Mpa | Psi | MPa | Psi | ||||||

1-5-21 | 4.5-5.5 | 9.5±0.6 | 14±0.8 | 21 | 3043 | 31.5 | 4564 | 63 | 9129 | 90 | 0.25 |

1-6-20 | 5.5-6.5 | 11.7±0.6 | 16±0.8 | 20 | 2898 | 30 | 4347 | 60 | 8694 | 100 | 0.34 |

1-8-17.5 | 7.5-8.5 | 13.7±0.6 | 18±0.8 | 18 | 2536 | 27 | 3804 | 54 | 7607 | 115 | 0.41 |

1-10-16 | 10±0.5 | 15.7±0.6 | 20±0.8 | 16 | 2318 | 24 | 3478 | 48 | 6955 | 130 | 0.47 |

1-13-14 | 13±0.5 | 19.7±0.6 | 24±1.0 | 14 | 2028 | 21 | 3043 | 42 | 6086 | 180 | 0.70 |

1-16-12 | 16±0.5 | 22.7±0.8 | 27±1.0 | 12 | 1739 | 18 | 2608 | 36 | 5216 | 205 | 0.84 |

1-19-10 | 19±0.5 | 25.7±0.8 | 30±1.0 | 10 | 1449 | 15 | 2174 | 30 | 4347 | 240 | 0.95 |

1-22-9 | 22±0.5 | 28.7±0.8 | 33±1.0 | 9 | 1304 | 13.5 | 1956 | 27 | 3912 | 280 | 1.09 |

1-25-8 | 25±0.5 | 32.2±0.8 | 37±1.0 | 8 | 1159 | 12 | 1739 | 24 | 3478 | 300 | 1.38 |

1-32-6 | 32±0.5 | 39.2±0.8 | 44±1.2 | 6 | 869 | 9 | 1304 | 18 | 2608 | 420 | 1.80 |

1-38-5 | 38±0.7 | 45.2±0.8 | 50±1.2 | 5 | 725 | 7.5 | 1087 | 15 | 2174 | 500 | 1.38 |

1-51-4 | 51±1.0 | 58.2±0.8 | 63±1.5 | 4 | 579 | 6 | 8694 | 12 | 1739 | 630 | 1.80 |

1-64-2.5 | 64±1.0 | 71±0.8 | 75±1.5 | 2.5 | 362 | 3.75 | 543 | 7.5 | 1087 | 770 | 2.40 |

1-76-1.5 | 76±1.0 | 84±0.8 | 88±1.5 | 1.5 | 217 | 2.25 | 326 | 4.5 | 652 | 930 | 2.95 |

1-89-1 | 89±1.0 | 99±0.8 | 103±1.5 | 1 | 144.9 | 1.5 | 217 | 3 | 435 | 1100 | 3.24 |

1-102-1 | 102±1.0 | 111±0.8 | 115±1.5 | 1 | 144.9 | 1.5 | 217 | 3 | 435 | 1250 | 3.85 |

1-127-1 | 127±1.0 | 136±1.0 | 141±1.5 | 1 | 144.9 | 1.5 | 217 | 3 | 435 | 1500 | 4.80 |

1-152-1 | 152±1.0 | 162±1.0 | 167±1.5 | 1 | 144.9 | 1.5 | 217 | 3 | 435 | 1800 | 5.80 |

1-203-1 | 203±1.0 | 214±1.5 | 220±2.0 | 1 | 144.9 | 1.5 | 217 | 3 | 435 | 2300 | 8.80 |

二层钢丝编织胶管技术参数

软管规格 | 内径 | 钢丝层直径 | 外径 | 工作压力 | 试验压力 | 爆破压力 | 最小弯曲半径 | 参考重量 | |||

MPA | Psi | Mpa | Psi | MPa | Psi | ||||||

2-5-60 | 5±0.5 | 11.2±0.6 | 15±0.8 | 60 | 8694 | 90 | 13041 | 150 | 21735 | 90 | 0.40 |

2-6-60 | 6±0.5 | 13.5±0.6 | 18±0.8 | 60 | 8694 | 90 | 13041 | 150 | 21735 | 100 | 0.45 |

2-8-50 | 8±0.5 | 15.5±0.6 | 20±0.8 | 50 | 7245 | 75 | 10868 | 125 | 18113 | 115 | 0.62 |

2-10-53 | 10±0.5 | 16.5±0.6 | 24±0.8 | 53 | 7680 | 79.5 | 11520 | 132 | 19127 | 130 | 0.71 |

2-13-30 | 13±0.5 | 21.5±0.8 | 26±1.0 | 30 | 4347 | 45 | 6521 | 90 | 13041 | 180 | 0.93 |

2-16-34 | 16±0.5 | 24.5±0.8 | 30±1.0 | 34 | 4926 | 51 | 7390 | 85 | 12317 | 205 | 1.23 |

2-19-34 | 19±0.5 | 27.5±0.8 | 32±1.0 | 34 | 4926 | 51 | 7390 | 85 | 12317 | 240 | 1.38 |

2-22-16 | 22±0.5 | 30.5±0.8 | 35±1.0 | 16 | 2318 | 24 | 3478 | 48 | 6955 | 280 | 1.54 |

2-25-14 | 25±0.5 | 34±0.8 | 39±1.0 | 14 | 2029 | 21 | 3043 | 42 | 6086 | 300 | 1.54 |

2-32-11 | 32±0.5 | 41±0.8 | 40±1.2 | 11 | 1594 | 16.5 | 2391 | 33 | 4782 | 420 | 1.82 |

2-38-12 | 38±0.7 | 47±0.8 | 52±1.2 | 10 | 1449 | 15 | 2174 | 30 | 4347 | 500 | 2.44 |

2-51-10 | 51±1 | 60±0.8 | 65±1.5 | 8 | 1159 | 12 | 1789 | 24 | 3478 | 630 | 3.18 |

2-64-5 | 64±1 | 74±1 | 79±1.5 | 5 | 725 | 7.5 | 1087 | 15 | 2174 | 790 | 3.74 |

2-76-4 | 76±1 | 86±1 | 92±1.5 | 4 | 580 | 6 | 895 | 12 | 1789 | 920 | 4.77 |

2-89-4 | 89±1 | 99±1 | 106±1.5 | 3.5 | 507 | 5.25 | 761 | 10.5 | 1521 | 1060 | 5.73 |

2-102-4 | 102±1 | 112±1 | 118±1.5 | 3 | 435 | 4.5 | 652 | 9 | 1304 | 1200 | 5.05 |

2-127-4 | 127±1 | 137±1 | 143±1.5 | 3 | 435 | 4.5 | 652 | 9 | 1304 | 1450 | 6.72 |

2-152-4 | 152±1.0 | 164±1.0 | 169±1.5 | 2.5 | 362 | 3.75 | 544 | 7.5 | 1087 | 1800 | 8.20 |

2-203-2 | 203±1.0 | 261±1.5 | 222±2.0 | 2 | 290 | 3 | 448 | 6 | 869 | 2300 | 11.75 |

The1year

The1year

suction and discharge pipe

suction and discharge pipe

Mixing grouting machine

Mixing grouting machine

Rubber sealing articles

Rubber sealing articles

Silicone Elbow Hose

Silicone Elbow Hose

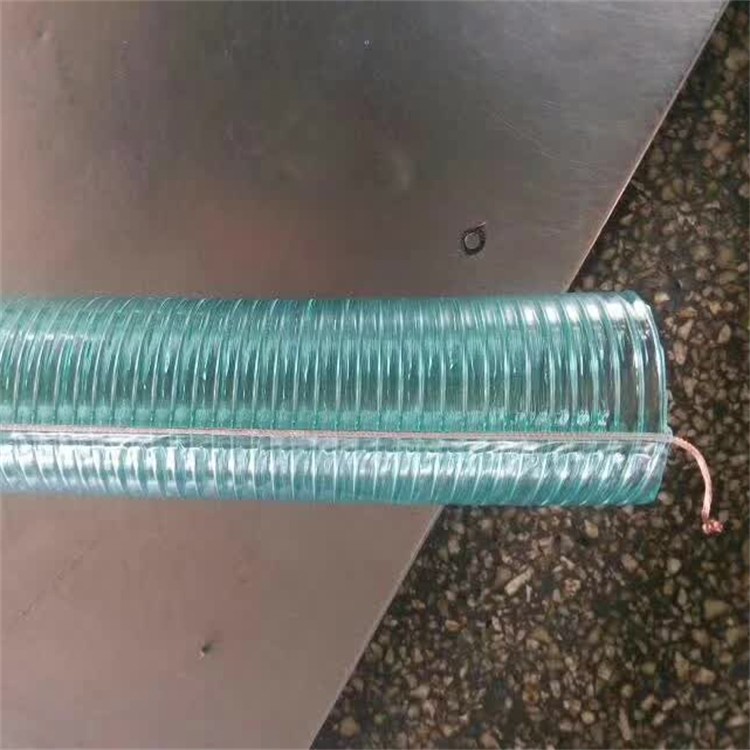

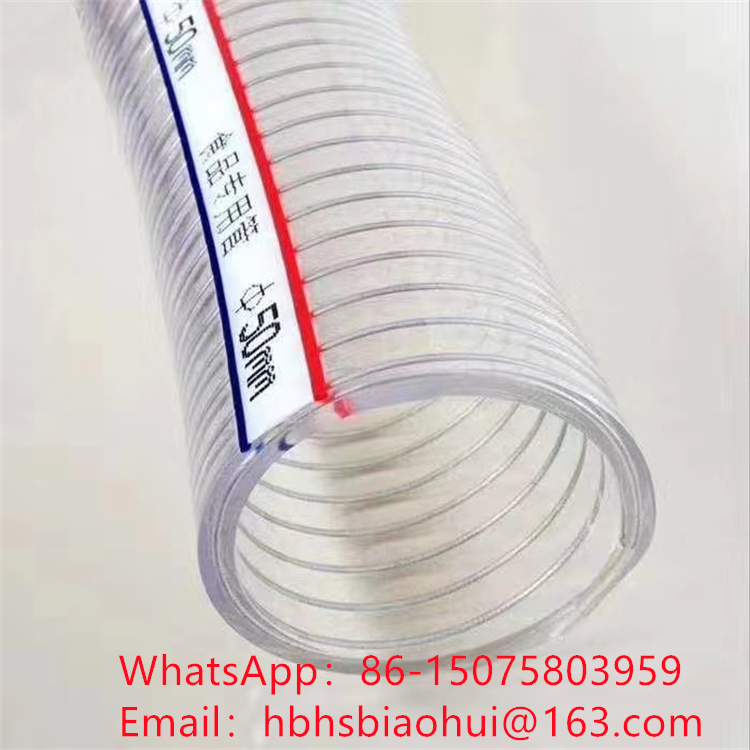

PVC steel wire pipe

PVC steel wire pipe

EPDM rubber plate

EPDM rubber plate

Concrete Placement Hose 85BAR

Concrete Placement Hose 85BAR

rubber sealing strip

rubber sealing strip

Silicone rubber hose

Silicone rubber hose

PVC pipette

PVC pipette