Sleeve valve pipe is used for reinforcement and grouting of soft foundation, loose soil and holding tunnel. It is applicable to dam, expressway, subway, tunnel and other projects.

Construction process:

(1) Surveying and setting out: calculate the coordinate position of the pilot hole according to the coordinates of the arranged control points, set out the hole position with a total station, measure the ground elevation with a level gauge, and determine the depth of the pilot hole

(2) Drilling: the casing wall protection water flushing method shall be adopted for drilling and the drilling depth shall reach the grouting consolidation section. Records shall be made during drilling to provide reference data for grouting operation.

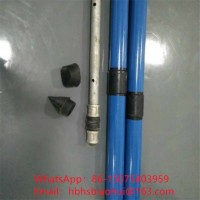

(3) Lower pipe: firstly, connect the sleeve valve pipe according to the depth of the pilot hole. The upper opening of the sleeve valve pipe is 20cm above the ground. Seal the lower opening of the sleeve valve pipe with a sharp bottom; Then, lower the sleeve valve tube into the hole, and ensure that the sleeve valve tube is lowered to the bottom of the hole.

(4) Hole washing: clean the hole with high-pressure water to reduce the proportion of sediment and mud in the hole;

(5) Sealing: the distance from the ground around the orifice to 1m below the ground shall be sealed with quick setting cement mortar to prevent the occurrence of grout bleeding during grouting. one

(6) Grouting: sectional grouting is adopted, and the grouting length of each section becomes the grouting step. The length of open steel pipe is the grouting step length.

The grouting step is generally 0.6~1m, which can effectively reduce the influence of stratum heterogeneity on the grouting effect. For sand layer, the grouting step distance should be low; For pebble or broken rock stratum, the grouting step distance should be high. During grouting, after each section of grouting is completed, the length of core pipe shall be moved up or down for one step. Lifting equipment should be used for moving, or 2 pipe tongs should be used to clamp the core pipe symmetrically manually, and both sides should use uniform force at the same time to move the core pipe. A section of grouting core pipe shall be removed every 3~4m grouting length. After grouting, the upper opening of the grouting pipe shall be covered to facilitate the re grouting construction.

Compared with the traditional anchoring process:

1. The hollow design enables the anchor rod to realize the function of grouting pipe and avoid the mortar loss caused by pulling out the grouting pipe in traditional construction technology.

2. The grouting is full, and the pressure grouting can be realized, which improves the project quality.

3. Due to the role of various accessories, the rod body is well centered. Mortar can wrap the whole length of the anchor rod, avoiding the risk of corrosion, and achieving the purpose of long-term support.

Sleeve valve grouting hole spacing is 2.0m × 2.0 m quincunx layout; The sleeve valve tube has the same length as the hole height, and the casing material is poured to the top of the hole. The bottom of the soil cave may be connected with the karst cave, which is easily affected by groundwater. In order to avoid groundwater diluting or taking away the grout, a certain amount of accelerator shall be added or "intermittent quantitative sequential grouting method" shall be used for grouting at the bottom of the cave. The sequence is hole jumping grouting, with the quantitative grouting volume of 5.0m3 for each hole and the interval time of 12h.

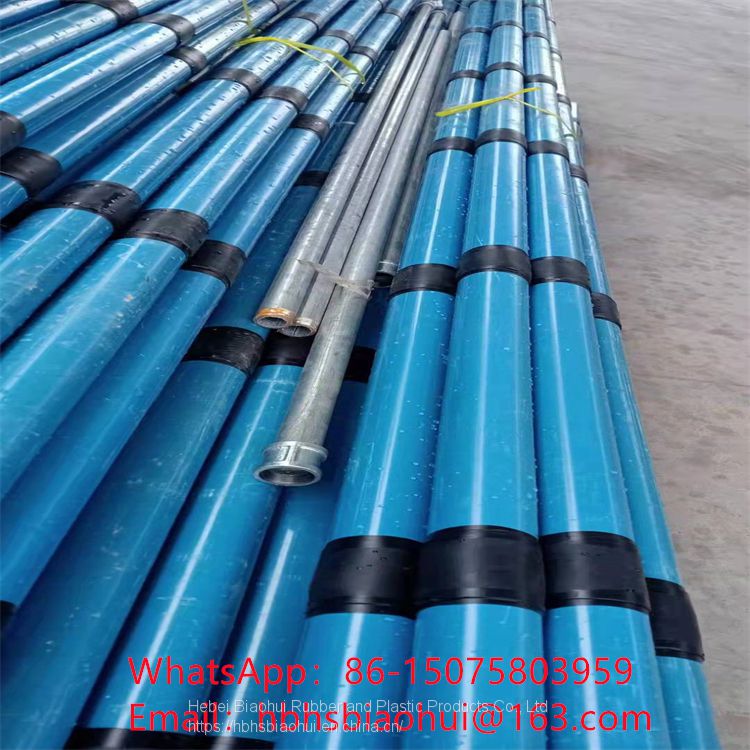

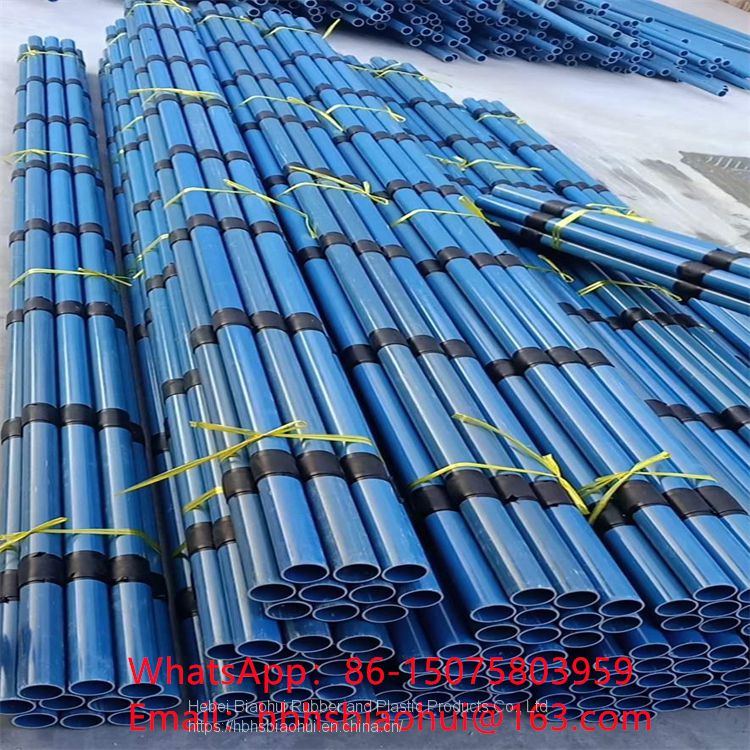

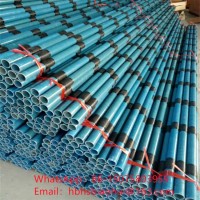

PVC sleeve valve pipe

Type: PVC

Working pressure: 1-10 (Mpa)

Product length: 4m (1, 2, 3m can be customized)

Outer diameter: 48mm

Inner diameter: 42mm

Wall thickness: 3mm

Product application: overall or local reinforcement of soft soil foundation

Hole cleaning: after the drilling is completed, the hole shall be cleaned, that is, the thick mud in the hole shall be replaced with thin mud. When the proportion of returned mud is less than 1.1, the hole cleaning can be completed. After hole cleaning, immediately inject casing material into the hole. Casting casing material: casing material is made by mixing cement and clay slurry in proportion (cement: clay: water: 1:1.5~1.53:1.9). Lower the tremie to 10cm from the hole bottom, and use the grouting pump to send the casing material to the hole bottom through the tremie, so that the casing material can completely replace the mud in the hole from bottom to top, until the casing material overflows from the orifice. The casting of casing materials must be carried out continuously without intermission. The time for pouring casing materials shall be as short as possible, and the time shall not exceed 20 minutes.

The1year

The1year

hose crimping machine

hose crimping machine

LPG hose

LPG hose

Mining Slurry Hose

Mining Slurry Hose

Composite Hose

Composite Hose

rubber conveyor belt

rubber conveyor belt

Large diameter crimping hose

Large diameter crimping hose

PVC anti-static hose

PVC anti-static hose

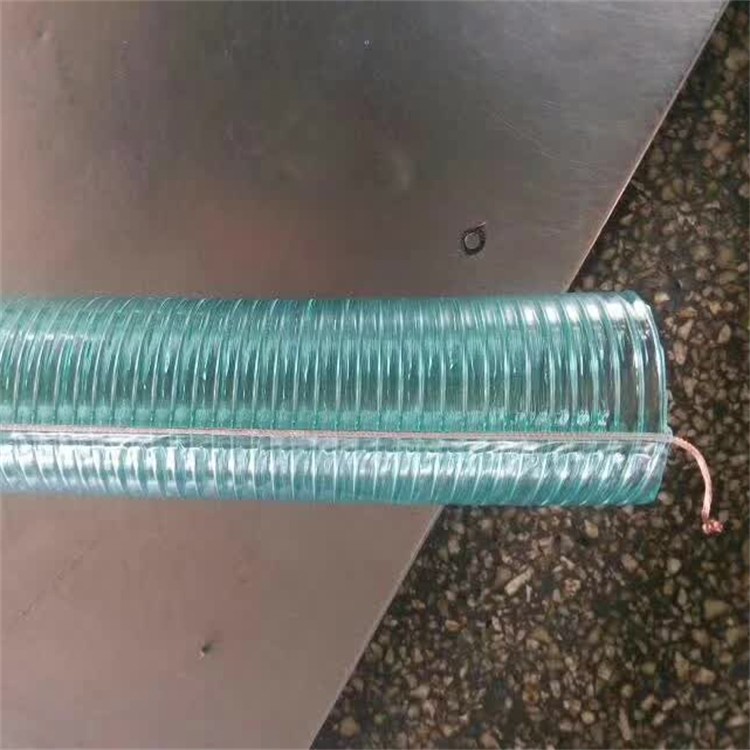

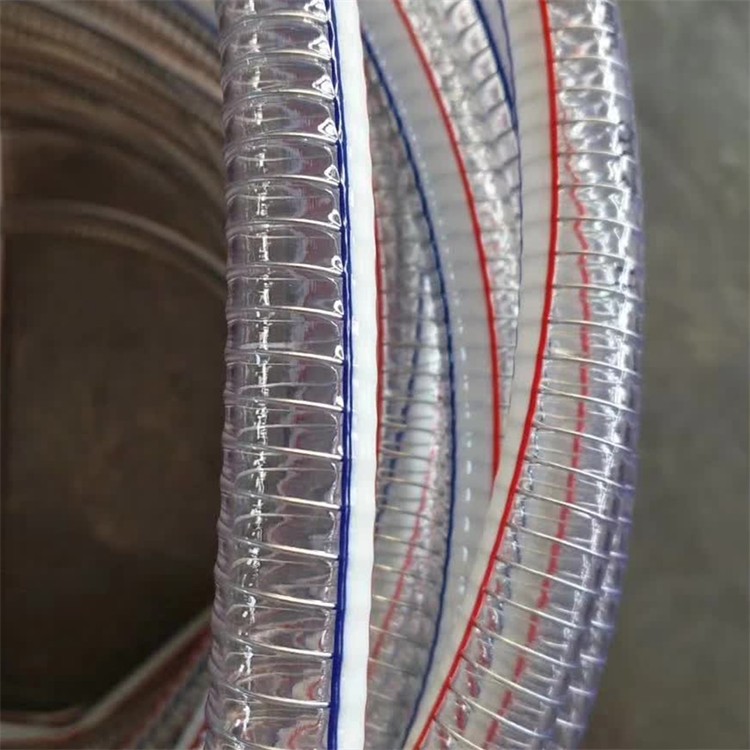

PVC steel wire hose

PVC steel wire hose

Helically Corrugated Hoses

Helically Corrugated Hoses

Electric drill grouting pump

Electric drill grouting pump