- Model:

- HP-FG1224

- Max cardboard feeding size:

- 1250×2400mm

- Max.design machine speed:

- 300 sheets/min

Automatic four color flexo printing machine with slotter and folder gluer strapping linkage line

★ Machine introduction:

1.This machine is component with the feeding unit,printing unit,slotting unit,die cutting unit,vibrator and stacker,can accomplish the process of the corrugate paperboard printing and slotting or die cutting.

2.The materials of the body is carbon steel, hearing treatment,thickness of body is 60mm,making by CNC machine,with high strength and high precision.

3.All the transmission gear is straight gear,with low noise and high precision,gears after high frequency heating and grinding,adopt automatic circle lubrication.

4.The gear material is 20CrMnti alloy steel,straight gear,after high frequency heating and grinding.and the main transmission gear and roller adopt expansion sleeve connection.

5.Bearing adopt the famous brand made in China like HRB and NSK.

6.The mail motor adopt frequency converters adjust,the frequency is “Siemens” brand,the PLC also adopt Siemens brand,the contactor adopt “Siemens” brand.the touch screen adopt Siemens brand.

7.The rubber roller adopt jingyang brand rubber roller, famous brand in China.

8.Ceramic roller adopt “Haili” brand, famous brand in China.

9.Rubber roller adopt jingyang brand made in China.

10. rubber anvil is Roticut,Span brand.

Main parameter

⑴. Max.design machine speed: 300 sheets/min.

⑵. Max. paper coverage area:1250×2400mm

⑶. Min. paper coverage area:380(full block print)×650mm.

⑷. Effective print area:1200×2400mm.

⑸. Printing precision: ≤±0.5mm.

⑹. Slotting and die-cutting precision: ≤±1mm.

⑺. The standard thickness of the printing plate:7.2mm.

⑻. Skip feeding size is 1450×2400mm.

⑼. Max. slotting depth:320mm

⑽. Min. slot distance:235×65×235×65mm

⑾. Wallboard thickness:60mm

Cardboard feeding unit(one unit)

⑴. Unit moving

①Each unit is electric moving left and right with warning bell. When unit moving, the bell will be warning to make sure the operator safe. The moving motor with constant torsional moment which can buffer the impact of the two units when the operation is wrong.

②After all the units closed, each part is pneumatic locked. There is also lead locked cylinder which can make each part locked with bottom-track lock. If the cylinder is not locked, the main motor will not work.

⑵. Lead edge feed system

①.The Lead edge feed unit gear is made in Guangzhou HengChuang ,with long life,and high precision for feeding.

The printing Unit(4 units)

⑴. The printing roller

①. The printing roller is steel material, after heating treatment and after balance correction.

②. Diameter is 395.6mm(without printing plate thickness)

③. The surface of the printing roller is grinded, polished and hard chromium plating.

④. The-printing-plate-reel structure is adopted. The pedal switch control the printing roller run clockwise and anticlockwise, makes change printing plate easy.

⑤. A complete slot in the printing roller for hung the printing plate,the size of the slot is 9mm×3mm.

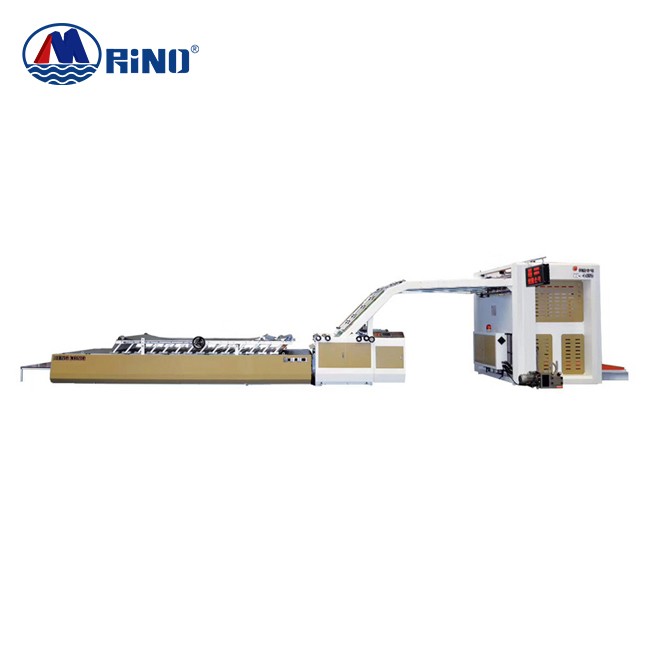

1.Whole machine introduction

1. PLC inline control,fast and convenient order adjusting。

2. Elastic transmission wheels device,upper and lower belt clamping transmission。

3. Blower cutting waste clean system

4. U.S. Varco glue system to improve adhesion and save glue,flue given quantity can be automatic adjustment accord running speed.

5. Extended high strength folding box bridge beam to ensure box folding accuracy and high speed stability。

6. Adopt linear guide rail synchronous traverse system,and the middle high-strength type bridge group support makes stable and accurate displacement.

7. Elastic guide rail pressing wheels system can control the clearance,effectively solve the paper blockage problem during transferring.

8. Rear adsorption belt transmission,independent motor deviation correction device on both sides,effective correction.

9. Falling type collection system,effectively protect printing surface from damaging.High production adaptability.

10. High frequency box correction system,motor fan assisted paper drop,circulation transmission.

11. Multi-servo drive high speed counting and stacking collection system,efficient guarantee

12. Conveyor belt output,paper pressing wheels assistance,paper transfer out clearance electric adjustment.

13. Transversal movement electric adjustment of counting output unit.

The1year

The1year

Carton Folder Gluer Machine

Carton Folder Gluer Machine

Carton Box 2 Color Printer

Carton Box 2 Color Printer

Carton Box Stitcher

Carton Box Stitcher

High Speed Flute Laminator

High Speed Flute Laminator

Manual Die Cutting Machine

Manual Die Cutting Machine

NC Cut off machine

NC Cut off machine

Rotary Die Cutting Machine

Rotary Die Cutting Machine