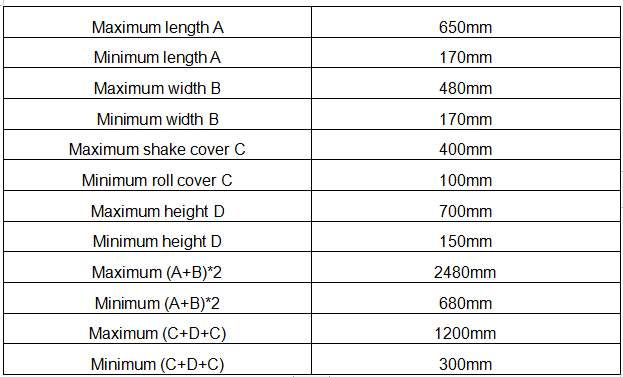

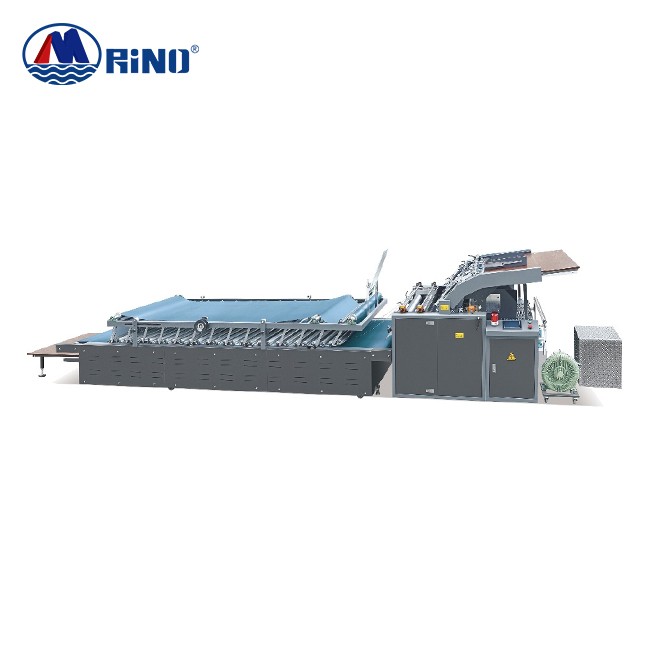

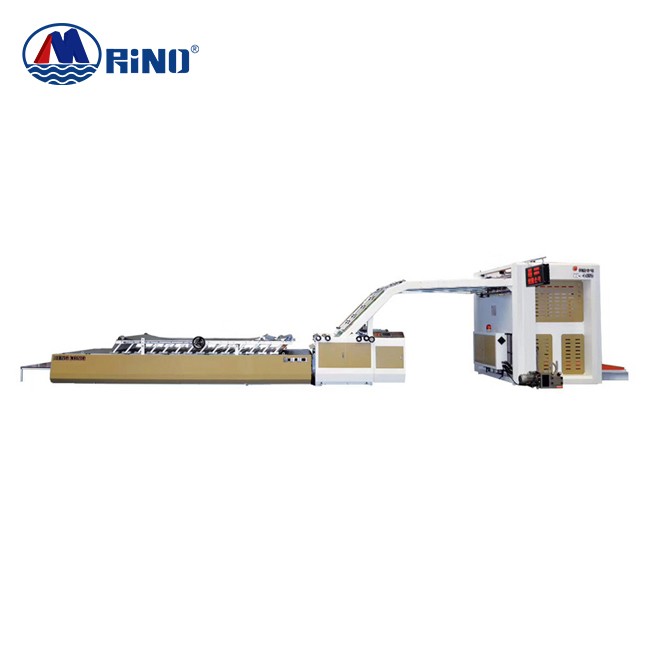

- Model:

- HS-FG2400

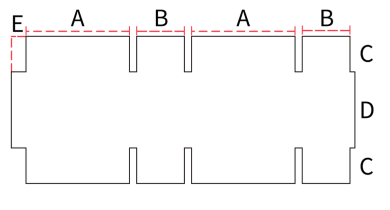

- Max cardboard feeding size:

- 2480*1200mm

- Minimum paper size:

- 680*300mm

Automatic Folding Gluing and Stitching Machine

Functions and features

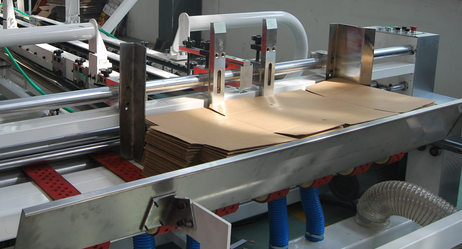

1. This machine is composed of five parts: paper feeding part, folding part, shaping and flapping part, nail box part, and stacking part. It can be used for nailing or gluing.

2. This machine adopts computer control, the operation is simple and easy to learn, convenient and fast.

3. The paper feeding part adopts adsorption-type leading edge belt to feed paper, and is equipped with side flapping device to ensure smooth paper feeding without skewing.

4. The folding part adopts the double pressing design and auxiliary pressing during the folding process to make the cardboard folding accurately and reduce the appearance of carton scissors. The conveying belt adopts high-quality belts with high wear resistance and high friction to make the cardboard conveying process smooth and smooth. standard.

5. The nail box part is directly driven by a servo motor. The nail head speed is 800 nails per minute. The cutting blade and the bottom die are made of tungsten steel. It is sturdy and durable. It can be used for single and double nails. It is equipped with an automatic wire feeding mechanism. Use 2 large reels of flat wire to reduce wire changing time.

6. The stacking department adopts computer control to automatically track the speed of the nail box, the man-machine interface enters the number of pallets and automatically sends out, the operation is simple and convenient (customers can choose automatic strapping machine)

7. Flat wire model: 17# (2.0x0.75), nail box slope: 45°

8. This machine can nail three or five layers of cardboard (seven layers and special-shaped cardboard need to be specified in advance)

Main Units

Paper feeding unit

1.Paper feeding is using vacuum belt transmitting mode, increase the reliability and accurately of the machine.Using high quality electromagnetic clutch and brake system,to make sure the paper feeding section can be controlled independently, and the operation is simple and reliable.

2. The front board and paper feeding belt can be adjusted left and right.

3.Wallboard are welded by steel plates.

4.The drive shaft is welded with seamless steel pipes, the wall thickness of the pipe is 20mm, the shaft surface is plated with hard chromium, and the bearings are made in Harbin Wafangdian.

Folding unit

1. The main motor adopts variable frequency speed regulation, the system has no noise, and the speed regulation is flexible and stable.

2. The imported high friction belt is used to convey the cardboard and automatically folded.

3. The folding part adopts the double pressing design and auxiliary pressing during the folding process to make the cardboard folding accurately and reduce the appearance of carton scissors. The conveying belt adopts high-quality belts with high wear resistance and high friction to make the cardboard conveying process smooth and smooth. standard.

Stitching Unit

1. Flat wire model: 17# (2.0x0.75), nail box angle: 45°

2. This machine can nail three or five layers of cardboard (seven layers and special-shaped cardboard need to be specified in advance)

3. The nail box part is directly driven by a servo motor. The nail head speed is 800 nails per minute. The cutting blade and the bottom die are made of tungsten steel. It is sturdy and durable. It can be used for single and double nails. It is equipped with an automatic wire feeding mechanism. Use 2 large reels of flat wire to reduce wire changing time.

The1year

The1year

Carton Die Cutter

Carton Die Cutter

Semi-auto Die Cutting Machine

Semi-auto Die Cutting Machine

Semi-auto flute Laminator

Semi-auto flute Laminator

Hydraulic Mill Roll Stand

Hydraulic Mill Roll Stand

Electic Mill roll Stand

Electic Mill roll Stand

Carton Flute Laminator Machine

Carton Flute Laminator Machine

Carton Box Stitcher

Carton Box Stitcher

Carton Box Die Cutting Machine

Carton Box Die Cutting Machine

Rotary Die Cutting Machine

Rotary Die Cutting Machine

Hot Stamping Machine

Hot Stamping Machine