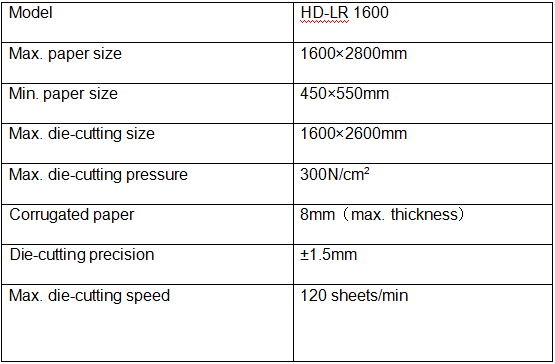

- Model:

- HD-LR1600

- Max cardboard feeding size:

- 1600*2800mm

- Minimum paper size:

- 400*700mm

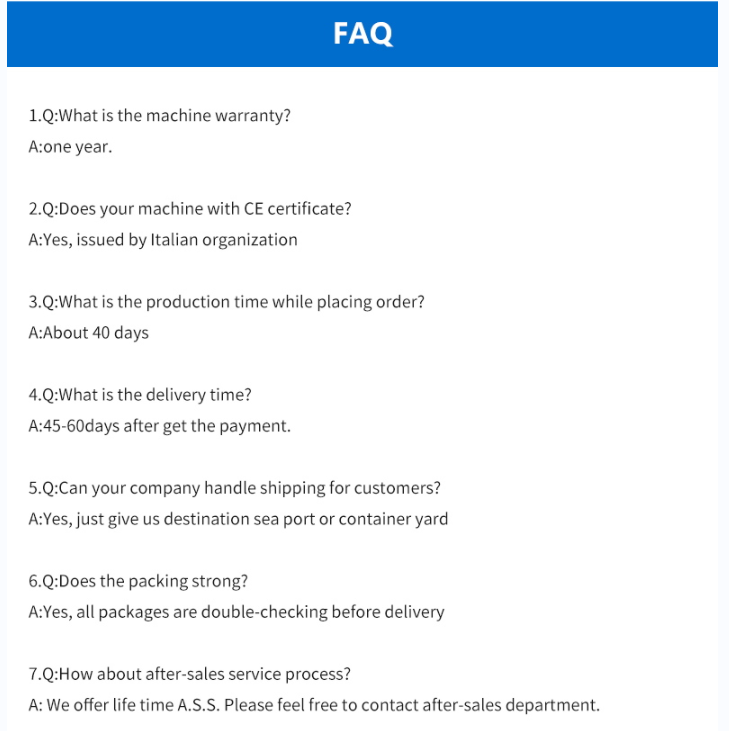

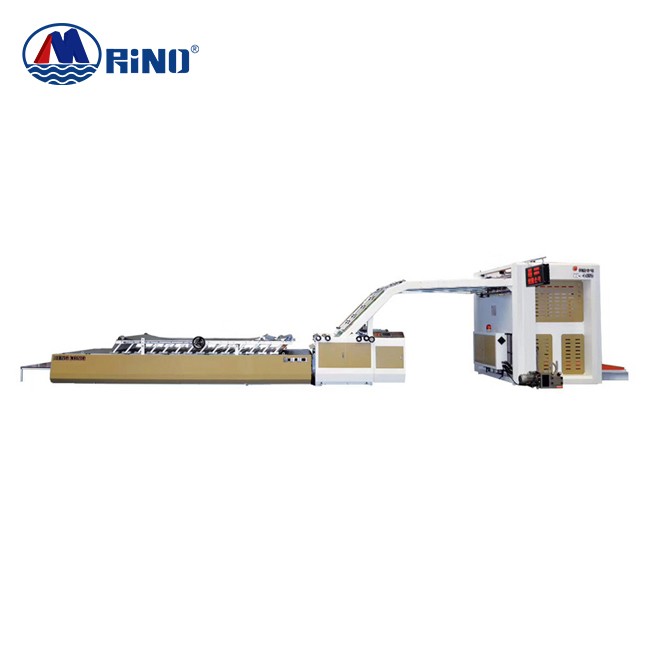

Lead edge feeding rotary die cutting machine

Main Unit of the equipment

Lead edge paper feeding unit

lLead edge feed paper refers to the front of the board as the benchmark, the speed of roller feeding is consistent with the speed of the feed shaft, and die cutting positioning is accurate

lFour axis roller lead edge feed mechanism, multi wheel, multi-point suction air feeding paper, friction, speed, paper stable and accurate

lSuction fan, high pressure centrifugal fan has large air volume, can adjust the air volume according to the warping degree of the paperboard, increase the stability and accuracy of the transmission of the thin paperboard and the warp corrugated cardboard

lNon side breakage technology to decrease transmission difference to min degree.

lUsing rubber roller and embossing steel roller to assist the paper feeding lightly. The pressure is light and the friction is large, which can effectively prevent the paper from damaging and affect the printing effect and the strength of the paperboard

lThe paper feeding rubber roller is made of high elastic rubber, wear resistant natural rubber, high temperature casting glue, excircle and deep groove grinder, and the balance correction is carried out.

lWithout equipping oil recycling and lubrication structure , and it is friendly to environment .

Die-cutting Unit

lIt utilizes soft rubber template. Speed differences can be compensated synchronously and automatically.

lOne-off processes of cutting, perforating and creasing can be completed in this machine.

lThe main motor adopts electromagnetic speed adjustment and the die cutter phase is adjusted by computer.

lThis machine comes with a number counter and alarm bell

lThe die cutting cylinder has been plated with hard chrome and treated by balance alignment. Driven by air, it will rise up and kiss the cushion roller when feeding starts, it will automatically go down and leave the cushion roller when feeding stops.

lThe cushion roller can move horizontally about 40mm, avoiding die cutting in the same place at the same time, thus prolonging its service life.

lLinear speed compensation device ensures uniform die cutting and thereby makes sure that the carton size is identical.

lThe rotary die cutter is designed with a spray lubrication system that enables gears to serve for long time.

The1year

The1year

Carton Flute Laminator Machine

Carton Flute Laminator Machine

Carton Box Stitcher

Carton Box Stitcher

2 Pieces Box Stitcher

2 Pieces Box Stitcher

Corrugation Production Line

Corrugation Production Line

Box Flexo Printing Machine

Box Flexo Printing Machine

Printer Gluer Inline FFG

Printer Gluer Inline FFG

PE strapping machine

PE strapping machine

Thin Blade Slitter Scorer

Thin Blade Slitter Scorer