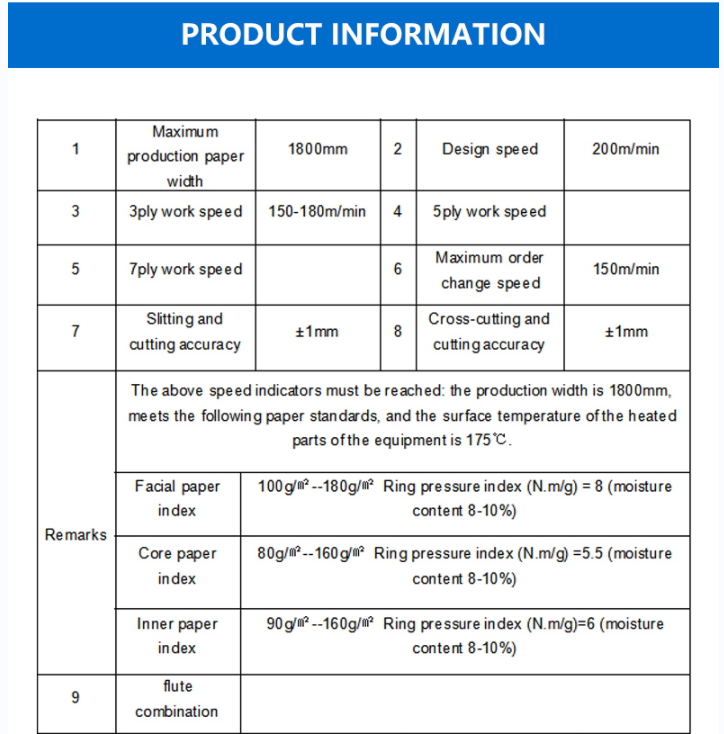

- Width:

- 1800mm

- Speed:

- 200m/min

- Length:

- 90m

Structural Features:

★ adopts cover suction construction with high pressure power fan. Air supply and sound elimination device, gas source and electrical control are concentrated in the same operation cabinet, not less than 1.5 m away from the main machine, and the operating side is completely closed.

★Cast iron structure of seat and wall panel, with wall thickness of 200mm. Independent transmission, universal joint transmission structure.

★ corrugated roller is made of 48CrMo alloy steel, corrugated main roller diameter of ¢ 360mm,, CNC grinder grinding, medium frequency quenching, surface polishing, surface tungsten carbide treatment, surface hardness above HV1200 degree. Key parts of the tile roll and pressure roller bearing adopt the American Timken to produce high temperature resistant bearing.

★ pressure roller ¢ 364mm, surface grinding and chrome treatment; cylinder control up and down movement, medium carbon steel 45, quality adjustment (with buffer).

General technical parameters:

1. Operating width: 1800mm 2, Operating direction: left or right (determined by the customer's workshop)

3. Design speed: 200m/min 4, Temperature range: 160-180 ℃

5. Gas source: 0.4—0.9Mpa 6. Steam pressure: 0.8—1.3Mpa

7. Corrugated type (Type UV or Type UVV):

Roller Diameter parameter:

1. Corrugated roller diameter: ¢ 360mm 2, Pressure roller diameter: ¢ 365mm

3. Rubber roller diameter: ¢ 240mm 4, preheater diameter: ¢ 400mm

Power motor parameters:

1. Main drive motor: 22KW rated voltage: 380V 50Hz continuous (S1) working system

2. Air suction motor: 22KW rated voltage: 380V 50Hz continuous (S1) working system

3. Film regulating reducer: 370W rated voltage: 380V 50Hz short-time (S2) working system

4. Rubber regulating clearance motor: 370W rated voltage: 380V 50Hz short time (S2) working system

5. Rubber pump motor: 2.2KW rated voltage: 380V 50Hz continuous (S1) working system

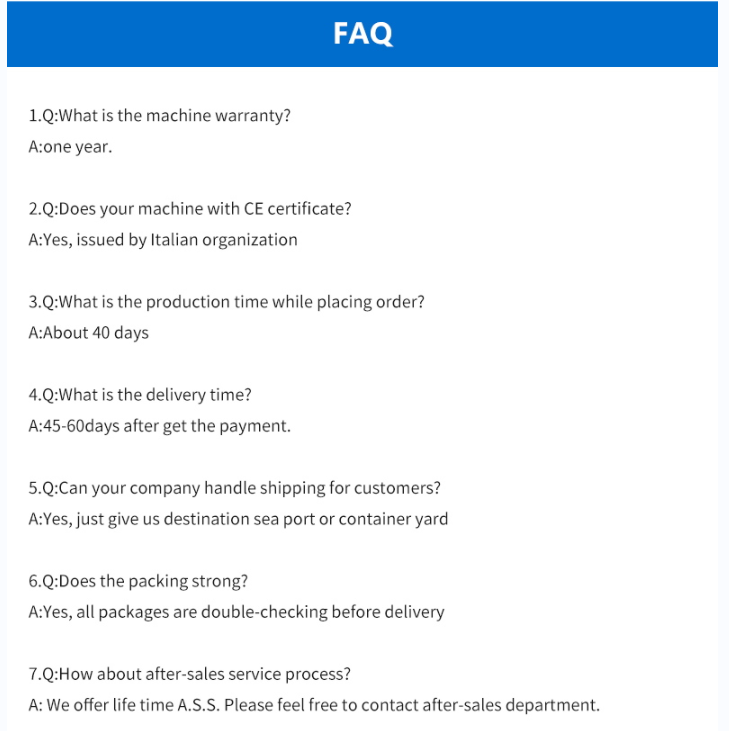

The1year

The1year

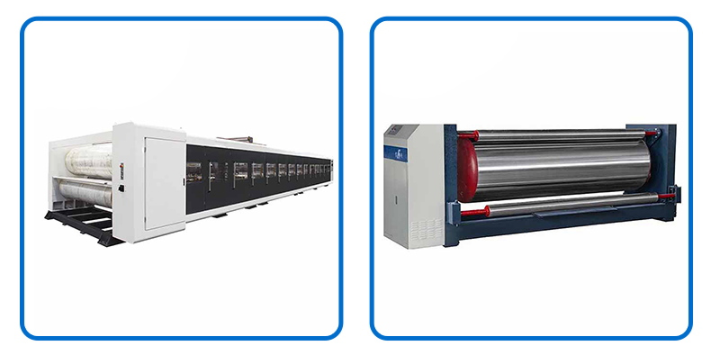

NC Cut off machine

NC Cut off machine

Carton Flute Laminator Machine

Carton Flute Laminator Machine

Large Size Box Flexo Printer

Large Size Box Flexo Printer

Folder Gluer Stitcher Machine

Folder Gluer Stitcher Machine

Rotary Die Cutting Machine

Rotary Die Cutting Machine

Carton Box Stitcher

Carton Box Stitcher

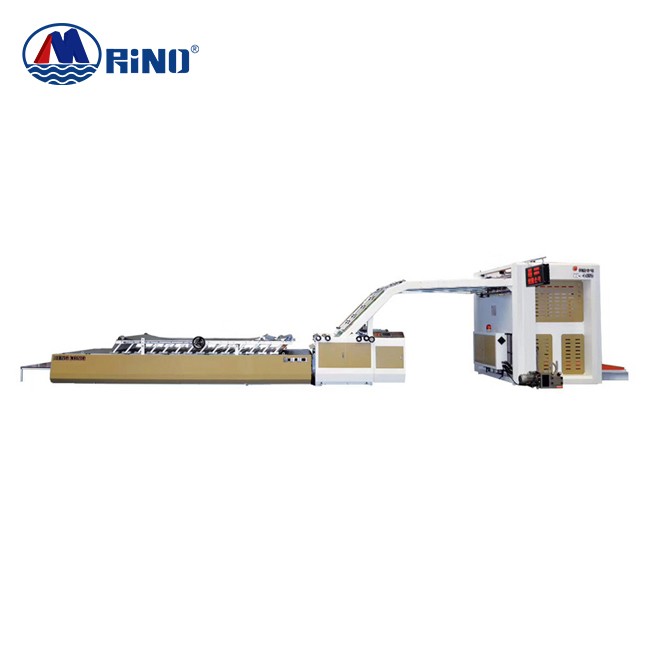

Single facer machine

Single facer machine

Carton Folder Gluer Machine

Carton Folder Gluer Machine

2 Pieces Box Stitcher

2 Pieces Box Stitcher