- Voltage:

- 220V/380V/440V/as requirements

- Bearing capacity:

- under 5Tons

- Warranty of core components:

- 12 months

5T Manual horizontal decoiler

Roof tile making machine consists of uncoiler and its base,infeed guides,fixed position driven forming stations,pressing die,shearing device,hydraulic station,PLC control console and so on.Our company has dozens of profile models for this series roll forming machine,We can design different kinds of profile and fittings for machine,as per customers’ requirement.

![]() Different decoilers&uncoilers.pdf

Different decoilers&uncoilers.pdf

if roll forming machine with hydraulic decoiler, worker only put coil on loading car, then press bottom to load coil onto hydraulic decoiler, whats’more, hydraulic decoiler has power to move forward and reverse, the most inportant is , there is sensor, which will monitor decoiler speed.

Therefore, hydraulic decoiler can improve roll forming machine degree of automation and efficiency.

And the decoiler we can do for so many differents loading weight,for 1ton,2.5tons.3tons,5tons,7/8tons,10tons and so on.

Our Company Main Roll Forming machines

1. Different types of roof profile drawing forming machine ;

2. Curve roof roll forming machine; 3. Ridge cap roll forming machine;

4. Floor deck roll forming machine; 5. Rain gutter roll forming machine;

6. Downpipe roll forming machine; 7. Highway guardrail roll forming machine;

8. Roller shutter door forming machine; 9. Door frame roll forming machine;

10. CZU purlin roll forming machine; 11. Light keel roll forming machine;

12. Slitting machine (lines); 13. Shearing/bending machine;

14. Decoiler(Hydraulic decoiler, electric decoiler and manual decoiler) and so on

How to Contact with us:

Tel&Whatsapp:+86-15612977437

Email:Una@hbsxmachinery.com

The1year

The1year

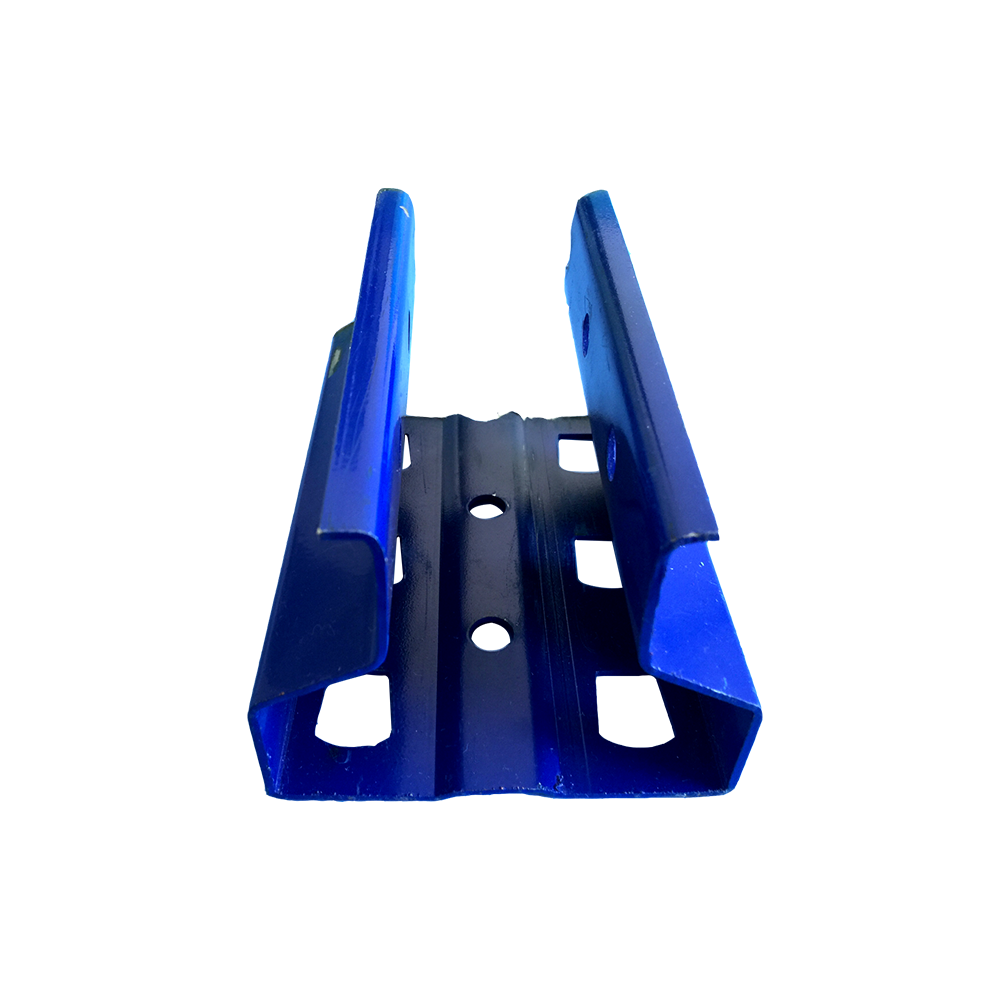

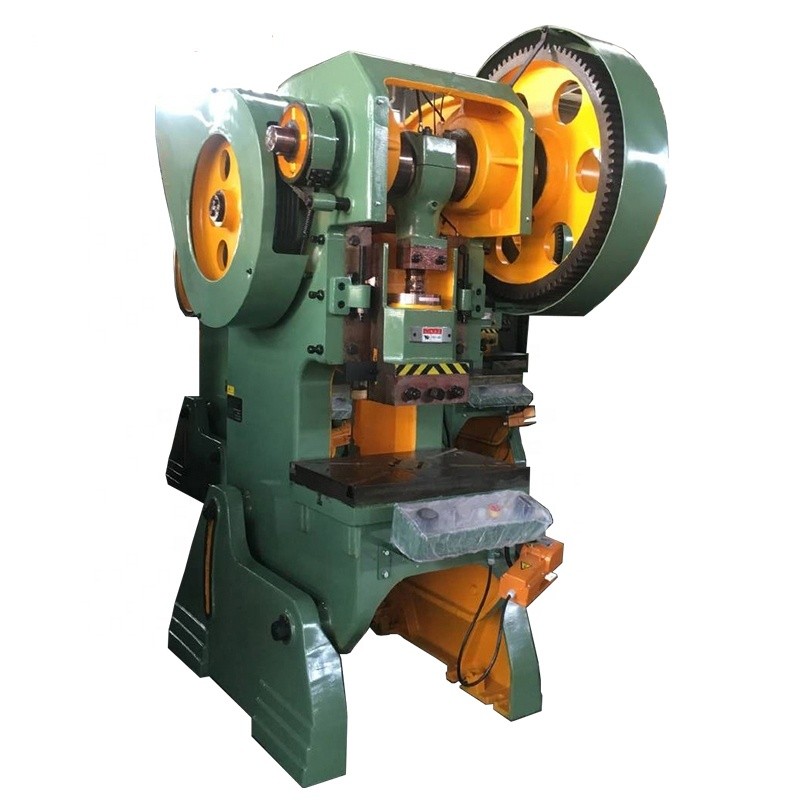

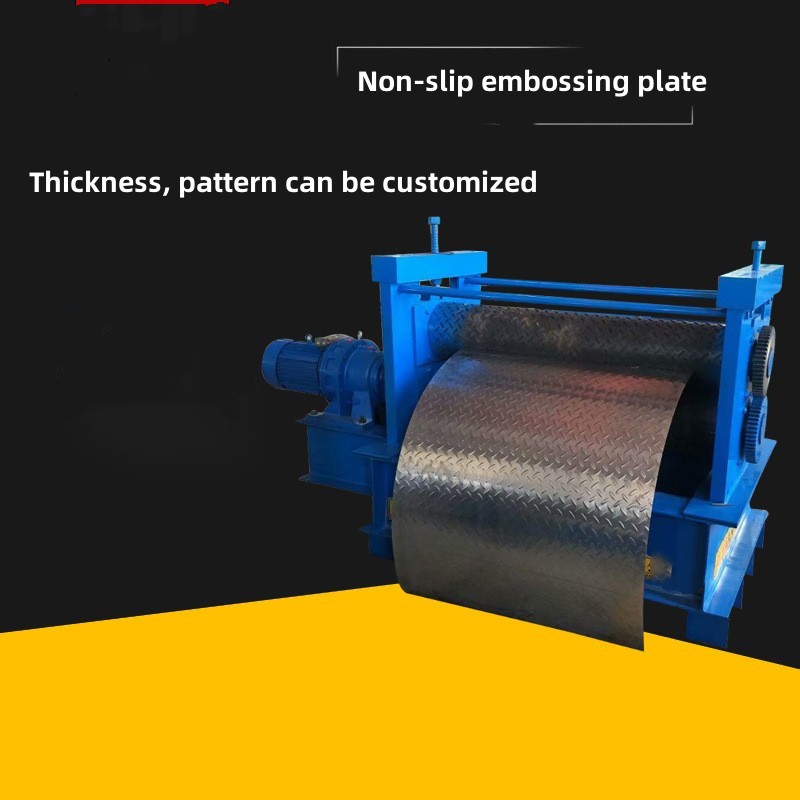

carving plate knurling machine

carving plate knurling machine

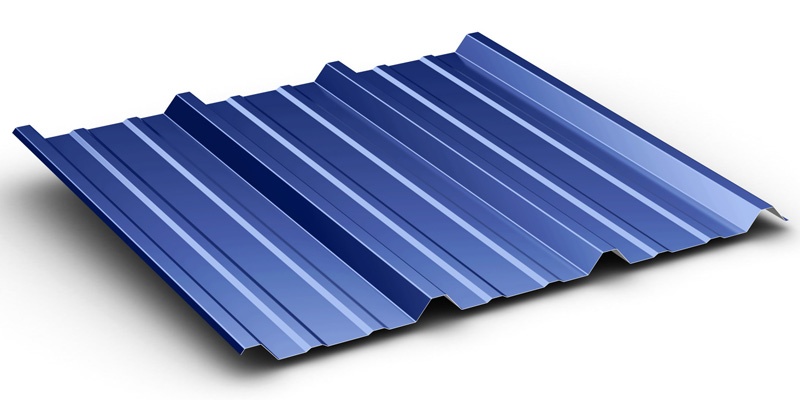

840 R roll forming machine

840 R roll forming machine

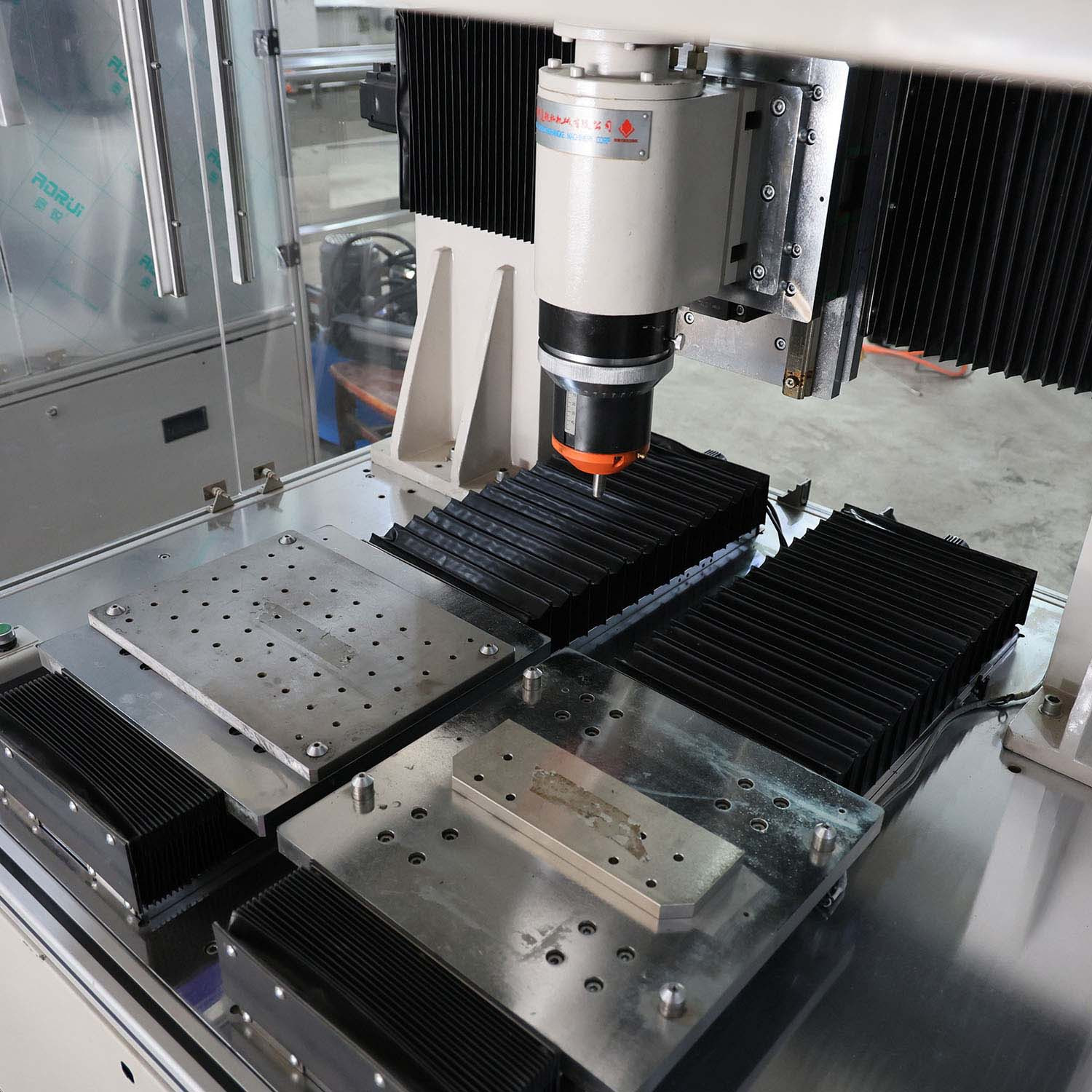

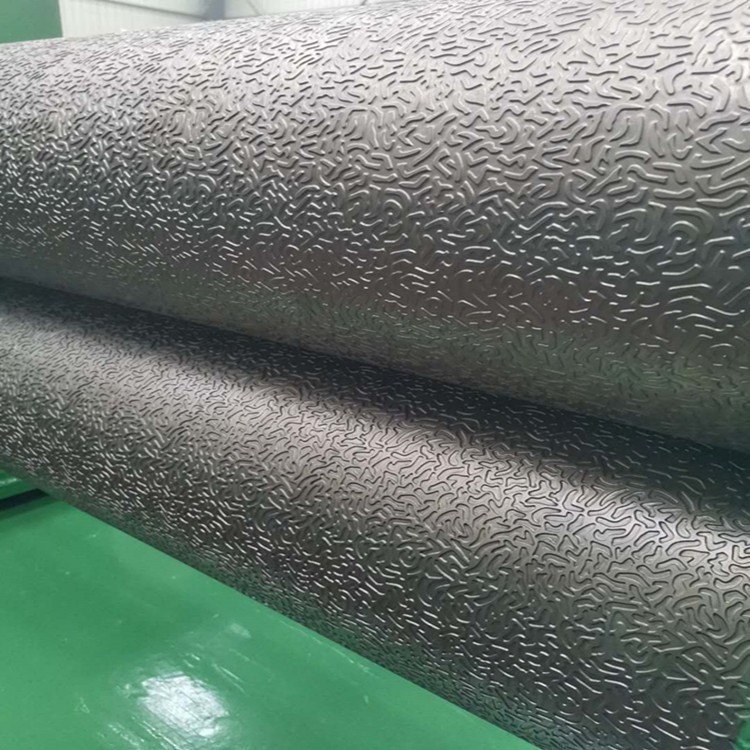

CNC sheet embossing machine

CNC sheet embossing machine

840 IBR roof sheet machine

840 IBR roof sheet machine

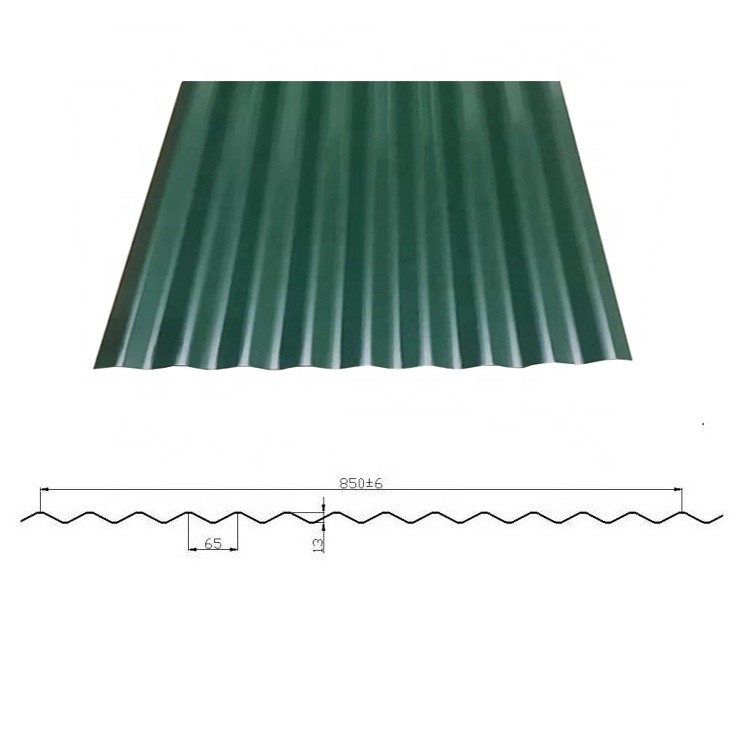

Corrugate roll forming machine

Corrugate roll forming machine

Double layer forming machine

Double layer forming machine

7/8T hydraulic decoiler

7/8T hydraulic decoiler