- working pressure:

- 0.5-2.5MPa

- Applicable temperature:

- ≤500℃

- Suitable medium:

- Gas and toxic, harmful and flammable gases

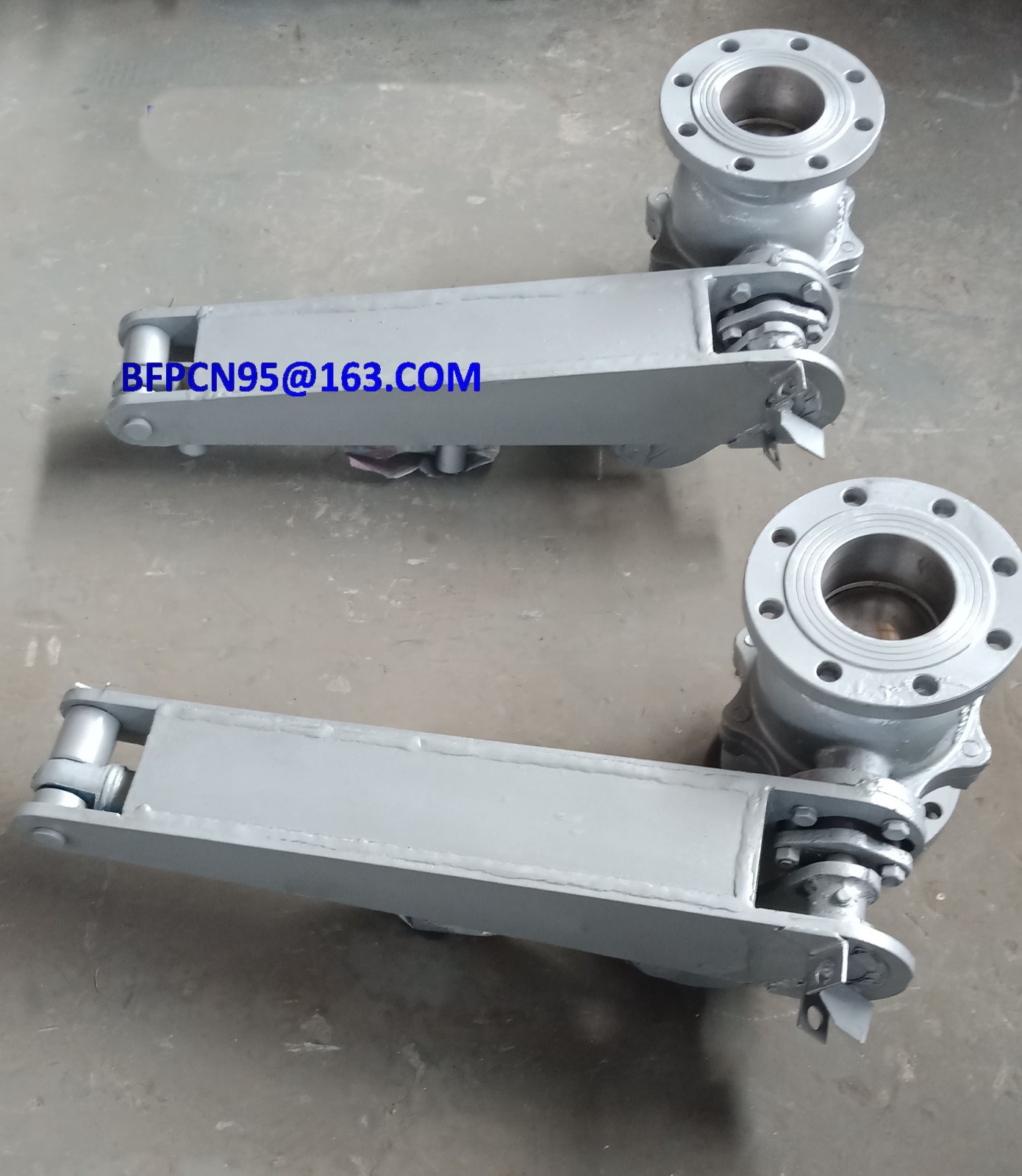

The three-bar cut-off butterfly valve includes the valve body, the valve plate and the driving device. The valve plate is opened and closed by a four-bar mechanism. The four-bar mechanism includes an active rod fixed to the main transmission shaft, a two-follower rod between the transmission shaft and the valve plate, and a valve plate. The valve plate support is arranged on the valve plate, the active rod is connected with the valve plate support, and the two follower rods are connected with the transmission shaft and the valve plate support respectively. The butterfly valve drive device drives the main drive shaft to rotate, so as to drive the four-linkage mechanism composed of active rod, two-follower rod and valve plate to move relative to the valve body pedestal, select the appropriate connecting rod size, make the valve plate move according to the set running track, and realize the reliable valve opening and closing action. The lever cutting butterfly valve has the advantages of small structure size and light weight. The valve plate has a period of opening and closing translation process relative to the valve body at the moment of valve opening and closing, and the friction free operation can ensure the sealing performance of the sealing surface for a long time.

1、Suitable for blast furnace hot blast furnace system, can be used as cold air valve, gas (air) cut-off valve, gas (air) combustion valve, flue valve and so on. The utility model has the advantages of compact structure, light weight, small installation space, strict and reliable seal and long life.

Main Technical characteristics of connecting Bar cutting Butterfly Valve

The finite element analysis and design are adopted to optimize the size of the connecting rod system to ensure the reliable running track of the valve under high temperature and high pressure. At the same time, we adopt the special structure design of sealing compensation, coating, surfacing wear and corrosion resistant material, multi-layer sealing structure at the shaft end, etc., and the use of many patented technologies makes the connecting rod cutting butterfly valve have the characteristics of high temperature resistance, wear resistance and long life.

The1year

The1year

Gas bleeding valve

Gas bleeding valve

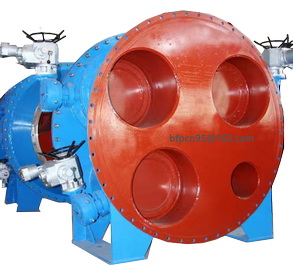

Semi-ball valve

Semi-ball valve

Emergency /quick shutoff valve

Emergency /quick shutoff valve

Horizontal butterfly valve

Horizontal butterfly valve

Ash release valve

Ash release valve

Gate valves

Gate valves

Explosion relief valve

Explosion relief valve