Product introduction

Roller screen is a kind of machine widely used in the separation technology. It controls the garbage separation by controlling the particle size, and the separation accuracy is high. The cylinder of the drum screen is generally divided into several sections, depending on the specific situation. The screen holes are arranged from small to large, and the screen hole diameter on each section is the same.

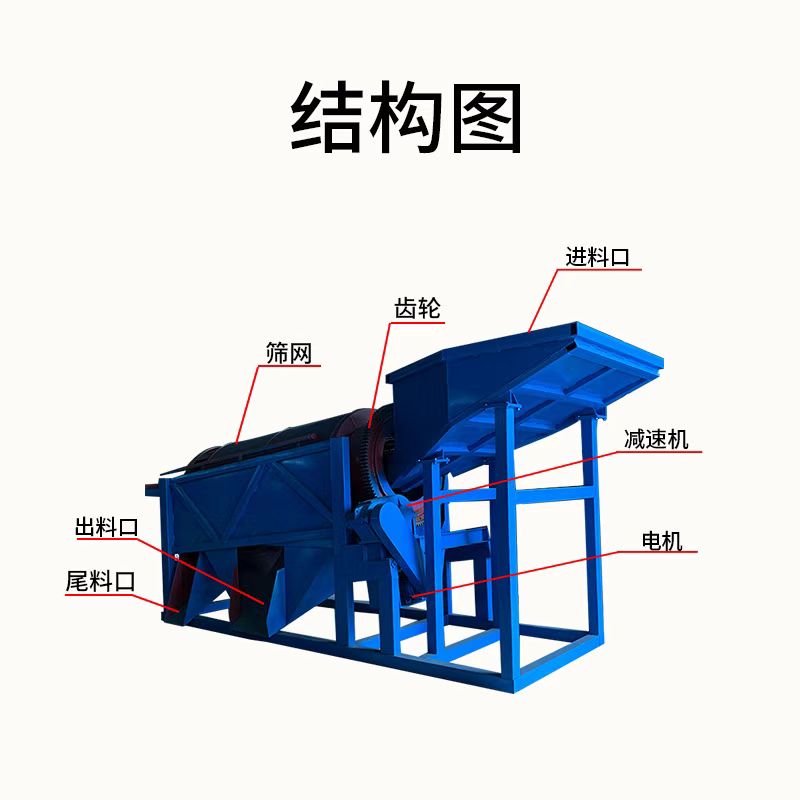

The drum screen is mainly composed of motor, reducer, drum device, frame, sealing cover and inlet and outlet.

The roller device is installed on the frame obliquely. The motor is connected with the drum device through the reducer through the coupling, and drives the drum device to rotate around its axis. When the materials enter the drum device, due to the inclination and rotation of the drum device, the materials on the screen surface turn over and roll, so that the qualified materials (products under the screen) are discharged through the discharge port at the bottom of the rear end of the drum,

Unqualified materials (products on the screen) are discharged through the discharge port at the tail of the drum. Due to the overturning and rolling of materials in the drum, the materials stuck in the screen hole can be ejected to prevent the screen hole from blocking. The principle and structure of drum screen sand machine, drum screen machine and drum screen are almost the same, because there are differences in people's understanding and nomenclature.

The drum screen is composed of five parts: drum, frame, funnel, reducer and motor. After the minerals enter the drum, on the one hand, they are screened with the rotation of the drum, on the other hand, the stones with large particle size flow forward along the slope of the drum, and are gradually screened out through screens of different mesh sizes. The small stones will fall into their respective funnels after screening, and then be transported out manually or sent to the finished product pile by gravity.

The roller screen is fine in workmanship and durable. The steel frame is welded with section steel, and the funnel has a large volume. It is made of steel plate. A plurality of funnels are provided for discharging materials respectively. The funnel mouth is connected with a flange, which can feed to both sides or one side, which is convenient for transportation or self flow, improves the output, and prevents blocking materials from wearing the screen and delaying production.

It is suitable for screening materials of various properties, such as placer gold, coal, coke, lime and other wet and easily blocked materials. The maximum product under the screen is <100mm, the middle is 10 ~ 50mm, and the maximum fineness can be ≤ 3mm.

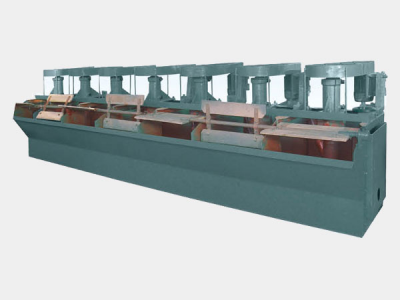

Product pictures

Performance introduction

Performance characteristics of roller sand screen:

1. The mesh is not easy to be blocked.

2. Stable operation and low noise.

3. Simple structure and convenient maintenance.

4. The whole machine has high reliability and less one-time investment.

5. Special screen is adopted, with high screening efficiency and long service life.

The1year

The1year

Rare earth tungsten tin ore titan

Rare earth tungsten tin ore titan

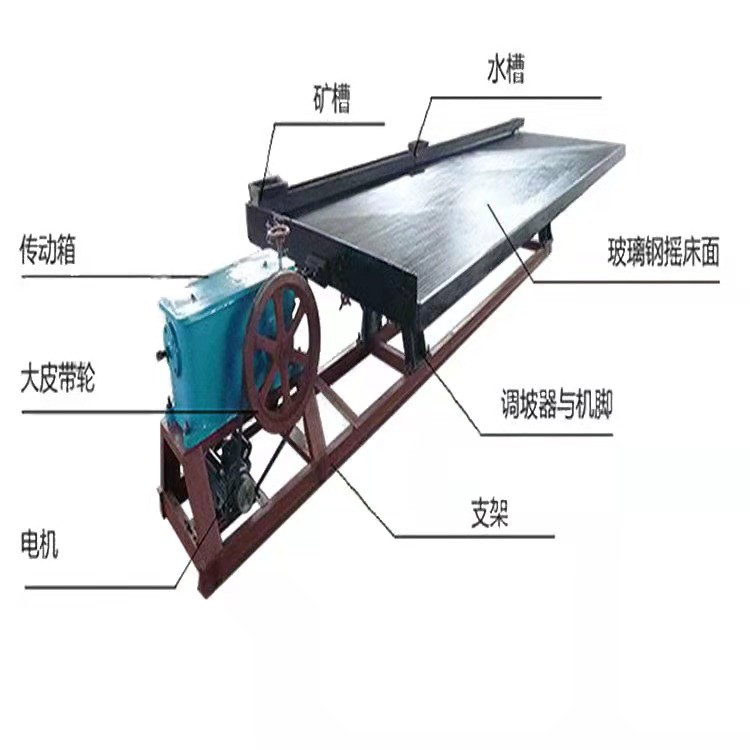

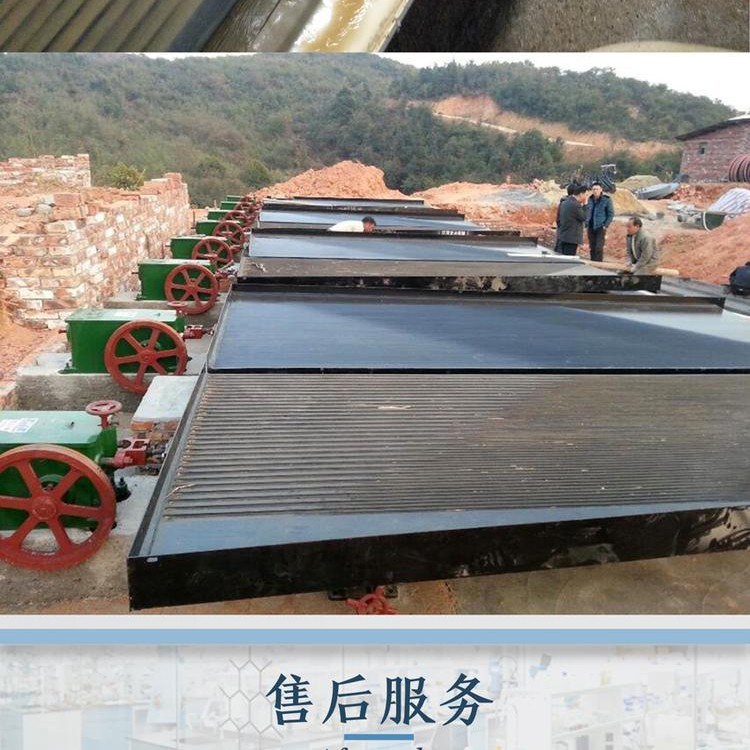

Gold dressing shaker

Gold dressing shaker

Gravity beneficiation spiral chut

Gravity beneficiation spiral chut

6S beneficiation shaker

6S beneficiation shaker

Copper ore, iron ore, placer gold

Copper ore, iron ore, placer gold

Gold mill

Gold mill