- Model NO.:

- Certification:

Product Description:

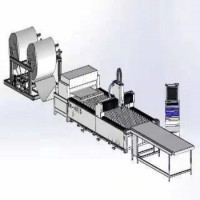

The pellet granulating machine is aspecial mechanical equipment for making high-density flammable high-quality granules from materials (sawdust, corn stalks, peanut hulls, straw, cotton stalks, branches, edible fungi waste, and cow dung).

The flat die granulator is atype of granulator which mainly presses the raw material into granules by vertical pressure. The biomass feedstock is fed into the feed compartment of the flat die machine and the material falls onto the flat die. The main shaft drives the grinding disc to rotate, and the pressing roller continuously rolls through the material layer to extrude the material into the die hole, and the material undergoes aprocess of forming and retaining in the die hole, and is extruded in acylindrical state after acertain time, and the cutter takes the material. The chips are cut to form granules, and the mashing tray feeds the granules.

Application:

Traditionally, people have relied on fossil energy sources such as coal, natural gas and oil for people's energy needs. However, fossil fuels are alimited resource that will eventually run out. Particles made from straw fuel pellets can be used as biomass fuels for industrial boilers and home heating and cooking. Awide variety of raw materials can be used, such as wood chips, wood blocks, rice husks, peanut hulls, wheat stalks, corn stalks, cotton stalks, sedges, and the like. Raw materials are easy to collect and cheap.

Specifications:

| No. | Model | Power | Capacity |

| 1 | ZLSP-150B | 5.5kw | 50-100kg/h |

| 2 | ZLSP- 200B | 7.5kw | 80-120kg/h |

| 3 | ZLSP- 230B | 11kw | 120-200kg/h |

| 4 | ZLSP- 260B | 15kw | 160-250kg/h |

| 5 | ZLSP- 300B | 22kw | 250-400kg/h |

Features and Advantages:

1.Wide range of processing, regardless of miscellaneous wood, pine, bamboo chips, peanut shells, rice husks, straw and other biomass materials we can now find, can make particles, without any additives.

2. The gearbox adopts multi-stage gear transmission. The gears are made of high-quality alloy steel, surface carburized and quenched. After grinding and fine processing, the transmission is stable, the noise is low, the bearing capacity is large, the temperature rises and the life is long.

3. The main shaft, the pressure roller shaft, the main shaft bearing and the pressure roller bearing are all enlarged, and the load can be more than doubled.

4, the use of large diameter pressure roller, large output, high granulation rate, uniform particles, high particle strength.

5. By changing the flat die hole arrangement form, the contact area between the flat die and the pressure roller is increased, which can greatly reduce the flat die wear speed and improve the flat die life (this has been applied for apatent).

6. All bearings adopt asealing structure to effectively prevent dust from entering, improve the bearing working environment and extend bearing life.

7. The shell is made of steel, the strength and toughness are greatly enhanced, and the shell fracture phenomenon will never occur.

Packing and Shipping:

For more information ,welcome to contact us freely:

The1year

The1year