- Model NO.:

- STZB

- Certification:

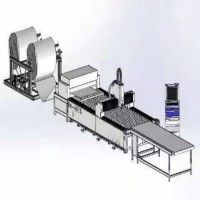

Product Description

The preferred curing equipment for shrimp pellet mill and high grade pig pelletizer.The volume of retentioneris increased and the steam jacket is heatedThe contact part with the material is stainless steel.Special spiral feed structure ensures first in first out, reduces residual and cross contamination.Product temperature can reach95c°-100c° and tempering time is 2 - 4 minutes. The particles tempered by retainer have the characteristics of high maturity, neat incision and good granulation performance.Detailed Photos

Product Parameters

| Modle | Effective Volume (L) | Diameter*length (mm) | Powder (kw) | Capacity(t/h) |

| STZB1000 | 1000 | 600*3000 | 5.5 | 3-12 |

| STZB1500 | 1500 | 800*3200 | 7.5 | 4-20 |

| STZB2000 | 2000 | 1000*3200 | 11 | 5-30 |

Liyang Sunrise Machinery Co., Ltd.is a professional manufacturer specialized in designing and making feed processing machine, sunrise company introduces a full set of world-class technology of CNC laser cutting machine, profile automatic sand blasting equipment, automatic paint room, shear bending equipment, specializing in the production of complete sets of feed machinery equipment and turn-key project.We have over 18 years experience in this field, since year 2003. We provide plant design, equipment manufacture, installation commissioning, personal training and other complete sets of one-stop service.

Liyang Sunrise Machinery Co., Ltd.is a professional manufacturer specialized in designing and making feed processing machine, sunrise company introduces a full set of world-class technology of CNC laser cutting machine, profile automatic sand blasting equipment, automatic paint room, shear bending equipment, specializing in the production of complete sets of feed machinery equipment and turn-key project.We have over 18 years experience in this field, since year 2003. We provide plant design, equipment manufacture, installation commissioning, personal training and other complete sets of one-stop service.

Russia, Australia, Fiji, France, Denmark, Czech, Jordan, Netherlands, Turkey, Pakistan, India, Indonesia,Thailand, Vietnam, Philippines, South Korea, Iran, Iraq, Nicaragua, Egypt, Algeria, Nigeria, Kenya, Canada, Malaysia, Panama, Latvia, Chile, Lithuania, Myanmar, Macedonia, Turkmenistan and so on.

FAQ1.

1: Are you a trading company or a manufacturer?

A: We are a manufacturer.

2. Q: How can I get to your company?

A: You can get a flight to Nanjing Airport. We are just about 40-50mins away from Nanjing Airport.

3. Q: How long is your guarantee?

A: One Year (Calculated from the equipment arrives the customer's side.). After this period we will definitely still support you when needed. You will be welcome to contact us with any problem .

4. Q: Will you send engineers to install the plant?

A: yes, but at an extra cost payable by the customer. Or you can get local contractors to do the installation and we send one supervising engineer.

The1year

The1year

Feed Process Machine Sifter Scree

Feed Process Machine Sifter Scree