- Model NO.:

- feed pellet mill

- Certification:

5T/H automatic chicken cattle poultry animal feed processing plant

Animal feed machine of cow sheep Dog Cat Fox Floating Fish Feed Pellet Food Making machine Feed pellet mill Cattle Sheep Pig Food feed Machine Extruder

Animal Feed Production Line

The feed production line plays for feed industry to produce pellet or powder feed for aqua, livestock and poultry. We are manufacturing animal feed making machine, for example, Chicken feed making machine, pig feed making machine, cattle feed making machine, fish feed making machine, poultry feed making machine for exportation.

Features

Compact, modular and containerized small feed mill with advantages of low investment, compact structure and flexible operation:

1. With reasonable technology, homogeneous grinding particles, high capacity and low energy consumption, it can produce1000-40000 tons mash and pellet feed per shift annually.

2. Modular Structure: The plant is compact, which occupies less floor space and has low requirement on the mill tower, also needs low investment in civil works. This structure is convenient for assembly and disassembly, facilitates the shipment and installation

3. High accuracy dosing system with centralized control: the analogue panel is adopted. All machines can be interlocked and safety, alarm device is available. The operation is simple and convenient

4. Wide applicable scope: The plant can produce both poultry & livestock feed and fish feed and is applicable for medium and small sized feed mills.

Animal Feed Pellet Mill

Feed Pellet Mill Machine Parameters

| Capacity | 1-2t/h | 3t/h | 5t/h | 6-8t/h | 10t/h | 15t/h | ||||||

| Pellet mil | SZLH250 | SZLH32 | SZLH35 | SZLH400 | SZLH420 | SZLH508 | ||||||

| Hammer mill | SWSP56*30 | SWSP56*40 | SWSP56*60 | SWSP56*60 | SWSP66*80 | SWSP112*40 | ||||||

| Mixer | SHW1.0 | SLHY1.0 | SLHY2.0 | SLHSJ1.0 | SLHSJ2.0 | SLHSJ2.0 | ||||||

| Cooler | SKLN11*11 | SKLN15*15 | SKLN15*15 | SKLN19*19 | SKLN19*19 | SKLN22*22 | ||||||

| Rotary screener | SFJH80 | SFJH100 | SFJH100 | SFJH130 | SFJH130 | SFJH150 | ||||||

| Crumbler | SSLG22*40 | SSLG15*100 | SSLG15*100 | SSLG15*150 | SSLG24*110 | SSLG24*165 | ||||||

| Fan | 4-72No4A | 4-72No5A | 4-72No5A | 4-72No8D | 4-72No8D | 4-72No8C | ||||||

| Cyclone | XL60 | XL90 | XL90 | XL120 | XL120 | XL150 | ||||||

| Boiler | LSG0.3-0.4 | LSG0.3-0.4 | LSG0.5-0.4 | LSG1.0-0.7 | LSG1.0-0.7 | LSG1.0-0.7 | ||||||

| Bucket elevator | TDTG26*16 | TDTG26*16 | TDTG36*23 | TDTG36*28 | TDTG36*28 | TDTG50*23 | ||||||

Production Sequence

1. Receiving and pre-cleaning Process

2. Grinding Process

3. Proportioning and mixing process

4. Pelleting Process

5. Sifting and cooling Process

6. Bagging Process

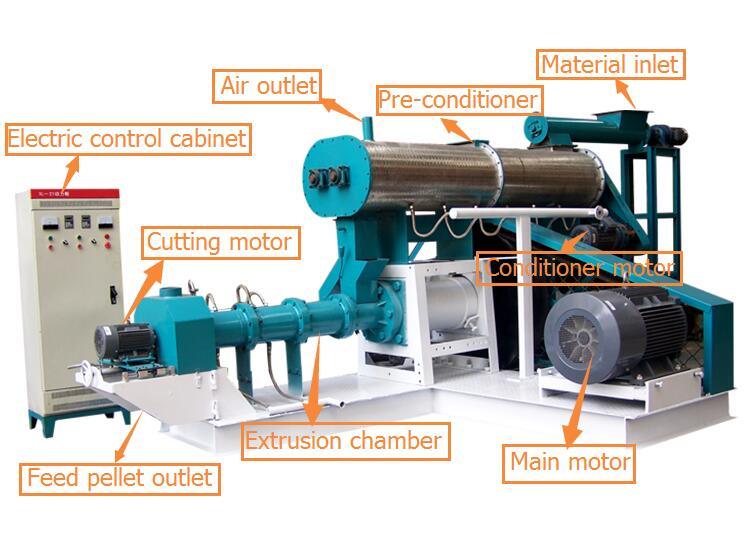

twin screw Floating fish feed extrusion machine

Floating Fish Catfish Shrimps CrabFeedPellet Food Making Make Production ProduceMachineLine

Model | Capacity | ScrewDiameter | MainPower | FeedingPower | CuttingPower | Conditioning Power |

DP60 | 180-200kg/h | 60mm | 15kw | 0.75kw | 0.75kw | 0.37kw |

DP70 | 250-300kg/h | 70mm | 18.5kw | 0.75kw | 0.75kw | 1.5kw |

DP80 | 350-400kg/h | 80mm | 22-30kw | 1.1kw | 0.75kw | 1.5kw |

DP90 | 500-600kg/h | 90mm | 37kw | 1.1kw | 1.1kw | 2.2kw |

DP120 | 700-800kg/h | 120mm | 55kw | 1.1kw | 1.1kw | 2.2kw |

DP135 | 1000-1500kg/h | 135mm | 75kw | 1.5kw | 2.2kw | 2.2kw |

DP160 | 1800-2500kg/h | 155mm | 90kw | 2.2kw | 2.2kw | 3.5kw |

DP200 | 3000-4000kg/h | 195mm | 132kw | 2.2kw | 3.0kw | 4.5kw |

Q: What's the difference between dry type extruder and wet type extruder?

A: The difference is the wet type need a steam boiler while the dry type doesn't. The dry type is cheaper than wet type, and the feed pellets made by wet type extruder is much smooth and with better quality.

Q: How long does the floating fish pellet float on the water surface?

A: The feed pellets can float on the water surface for over20hours.

Q: Does the fish pellet machine can only make feed pellets for fish?

A: No. It's not only can make high-grade aquatic feed pellets for fish, catfish, shrimps, crab etc., but also can make pellets for chicken,cat, dog, etc.

Q: Do you supply the wholefish feed production line?

A: Yes. We can supply a fish feed product line include crusher, mixer, fish feed pellet machine, feed pellet dryer, fish feed pellet cooler, oil spray machine and packing machine. The capacity is from 60-5000kg/h.

Q: Is there a formula of making fish feed pellet?

A: We can offer free formula to our customers.

about Service

We insist on "Quality is the soul of company" and take customers as our god, owned outstanding R&D team with the sense of innovation and cooperation, timely and effectively after-sales service team, professional installation guidance team with 30 years experience. We devote to all-round service of all the products from shipment to maintenance.

Our professional service includes: Free training, Guidance Installation and Debugging.

Guaranteed Time: One Year

If you have any question, please contact us freely. Our after-sales service team on-line will do the best to accomplish your sincere requirement on time.

Thank you for your reliance and support!

The1year

The1year

Chicken Farm Processing Feed Pres

Chicken Farm Processing Feed Pres