- Model NO.:

- SLG70

- Certification:

- CE ISO9001

1.Description of Commercial Animal Pet Pellet Extruder Equipment :

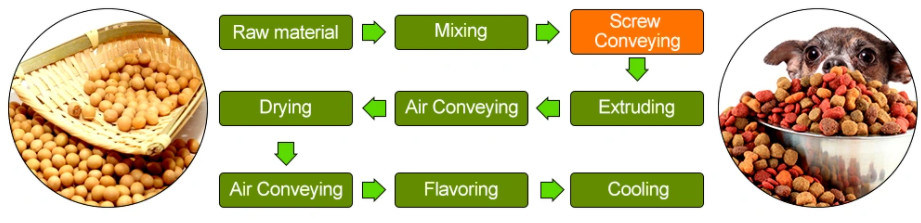

This 500 Kg/H Pet Food Making Machine uses meat meal, fish meal, corn powder, soya meal and other grains powder as main materials to make the pet food, such as dog, cat, fish, bird food etc. With different shapes and tastes by changing the dies and formulations. The pet foods are made under high temperature condition, and popular to the pet food market. Kibble Dry Cat Dog Food Making MachineAdvantage :

Kibble Dry Cat Dog Food Making MachineAdvantage :

1. It can suit various raw materials, such as corn flour, fish mill, meat mill and so on.

2.You can get various shapes of pet food, such as: rings, triangle, core flling pet food etc.

3.We not only have the basic pet food formula,but also the professional formula based on different age pets.

4.The machines performance and products quality reach to the most advanced level in the world.

5. High efficiency, low consumption, easy to operate and maintain.

1.RawMaterials:MeatMeal,FishMeal,CornPowder,SoyaMealandOtherGrainPowder

2.Products:PetFood,LikeDog,Cat,Fish,BirdFoodetc.withDifferentShapesandTastesbyChangingtheDiesandFormulations.

3.Animal Feed Dog Cat Pet Food Processing MachineCapacity:120-150KG/H,200-250KG/H,400-500KG/H,800-1000KG/H.

4.Voltage:Threephases:380V/50HZ,Singlephase:220V/50HZ,Wecanmakeitaccordingto customers'localvoltageaccordingtodifferentcountries.

6.Technical Parameter:| Model | SLG65 | SLG70 | SLG75 | SLG85 | SLG95 |

| Installed power | 76kw | 95kw | 130 | 178kw | 280kw |

| Production Capacity | 120-150kg/h | 200-260kg/h | 300-400KG/H | 400-600kg/h | 1000-1500kg/h |

| Size MM | 1600*1800*2000 | 1800*2000*2200 | 2200*2000*2200 | 2500*2600*3000 | 3000*3200*3500 |

7.Pet Food Making Machinemakingsample

This line can be used to produce fish pellets, the pellets size can be from 1.0 mm to 9.0 mm by adjusting the moulds from extruder; meanwhile it can produce dog food, cat food.....

8.Automatic Kibble Dry Cat Dog Food Making Machine Product Details:

Mixer→screw conveyor→twin screw extruder→air conveyor→dryer→hoister→flavoring drum and oil sprayer→coolingmachine→

packing machine

| 1 | Installed Power: 4kw Consumption:3kw/h Output: 30kg/batch-40kg/batch Mixing Time:(2minutes-3minutes)/batch Size: 1030*920*1350mm Function: raw material with water, liquid chemical additive mix together fully. Feature: 1.This part that contacts mixer to material adopts the stainless steel material. 2.The discharge hole adopts the new handle-opened design, good seal 3.Motor is Chinese famous brand |

| 2 | Screw feeder Application:convey the Power :0.75kw Capacity:equipment with the output Dimension:3100*590*2200mm Material:stainless steel |

| 3 | Twin-Screw extruder Installed Power: 53kw Consumption:37kw/h Output: 200kg/h-250kg/h Size: 2600*870*1950mm Features: 1.The main extruder adopts frequency speed controlling with high automation and stableper-formation. 2.The screws are made of the alloy steel and special craft, durable usage, high pressure,the screw life is longer. Adopting the building block structure and combining willinglyaccording to the different demand. 3.The forced lubrication system, can guarantee the equipment transmission life longer. 4.Auto-temperature control system makes the temperature control more direct viewingand the parameter more precise. 5.Self-cleaning , when stopping, it can be cleaned without disassembling. |

Air converyer Application:convey the shaped material to dryer oven Power:0.75,1.1,2.2kw(accorging to capacity) Capacity:100-150kg/h,220-250kg/h,800-1200kg/h Material:stainless steel | |

| 4 | Dryer Installed Power45kw Consumption: 30kw/h Output:200kg/h-300kg/h Size: 5200*1300*2200mm Function: Baking and drying the food. All kinds of the inflating food, pet food, TVP food, peanut, nut, chew nut can be dried. |

| 5 | Flavoring machine Application:To mix the oil and flavors on dry final pet food Power:0.75kw Type:single drum or double drum Capacity:100kg/h to 500 kg/h Material:Stainless steel |

| 6 | Installed Power: 1kw Output:According to Extruder Size:5000*700*1100mm Feature: 1.This material that contacts food adopts the stainless steel material. 2.The air from the fan cooling the rice going through the conveyor belt. 3.Motor is Chinese famous brand |

Packaging & Shipping

Inside: Plastic bags for the whole production line. Outside: Wooden case for the equipment.(According to our customer's demands.)

Firstly the machine packed with winding film or carton.Secondly fixed on bracket with wire. Finally packed with wooden case.

Company Information

JinanFLD Machinery Co,.Ltdis is a professional supplier of food processing machines. Our company's Motto is: "Service and quality are equally important". We offer to cooperate with our customers for mutual and beneficial development. All Inquiries are welcome.

We have through the years established good working relationship with some reputable organizations both at home and abroad with outstanding goodwill.

We are located in Jinan, the Capital of Shandong Province. We have a group of experienced experts and outstanding engineers who do provide the professional service delivery and installation. based on the clients specific requirement, we also design and produce the machines to order.

We are located in Jinan, the Capital of Shandong Province. We have a group of experienced experts and outstanding engineers who do provide the professional service delivery and installation. based on the clients specific requirement, we also design and produce the machines to order.

Our main products line include puffed snacks production line, core filling snack production, corn flakes/ breakfast cereals production line, pasta / pellet chips production line, kurkure production line, artificial rice production line, pet food production line, etc Most importantly, we also provide formulas, technology supports, machine inspection service, etc.

If you are interested in500 Kg/H Pet Food Making Machine,Kindly contact us!

The1year

The1year

Floating Fish Feed Pellet Making

Floating Fish Feed Pellet Making

Dry Animal Aquarium Floating Fish

Dry Animal Aquarium Floating Fish

Best Price Floating Sinking Fish

Best Price Floating Sinking Fish

Full Automatic Pet Dog Cat Food F

Full Automatic Pet Dog Cat Food F

Automatic Dry Floating Sinking An

Automatic Dry Floating Sinking An

Poultry Animal Rabbit Chicken Pel

Poultry Animal Rabbit Chicken Pel