- Model NO.:

- LT85 LT115 LT130

- Certification:

Shandong Arrow Machinery Co., Ltd has many types of extruders,they are high degree of automation. The equipment can realize one-key start of the host, real-time data storage, real-time monitoring, alarm reminder and other functions.

Design: Designed by 3D software, analogue simulation, and it is tested by computer automaticall, to ensure the require-ments of design precision.

Design: Designed by 3D software, analogue simulation, and it is tested by computer automaticall, to ensure the require-ments of design precision.Concept: Modular function, humanized system, diversified applications are always our pursuit. AHT Double Screw Extruderunder the advanced design concept can meet various demands.

Profession: Professional manufacturing and processing. This will ensure the accuracy and coordination among each co-mponent of the Extruder. Stable processing and low noise is the best proof. Precision: Precise food technology and material selection, which assure the using life of the extruder, minimizing the wearand tear of the screw and barrel.

Experience: More than twenty years experience on the domestic and international advanced Double Screw Extruder. Wehave produced different kinds of extrusion food, like Vegetable protein, corn flakes/ breakfast cereals, pellets, aquatic feed/pet food etc, it is enough to solve problems met during the production.

Application

Core Product Specification

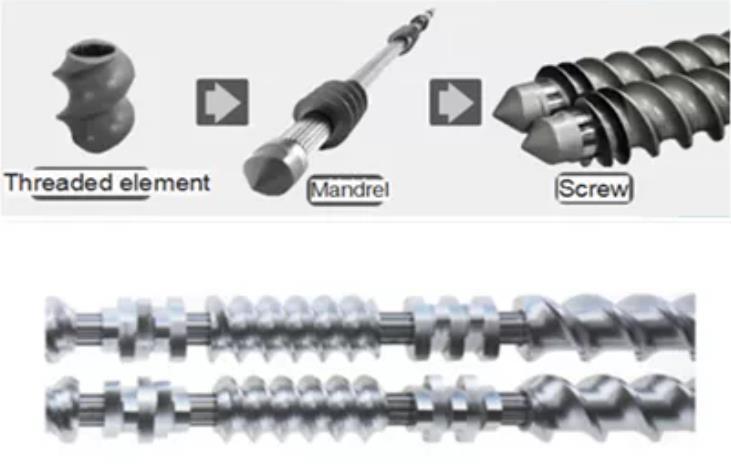

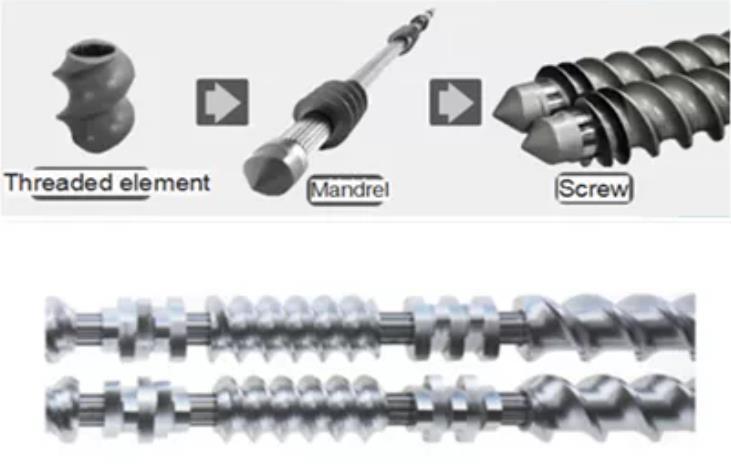

1) The screw is a combination modular structure, which can beassembled in any combination to meet different formula and product requirements.

1) The screw is a combination modular structure, which can beassembled in any combination to meet different formula and product requirements.2) The screw and the screw pieces are made of special alloy with high strength and high wear resistance.

3) The screw adopts fully engaged model, designed by 3D design,CNC machining, smooth surface, high conjunction accuracy,and better self- cleaning function, changing parts flexible.

4) The barrel is a combination of modular circular structure. Increased (or reduced) is very flexible and convenient;

5) Heating and cooling medium circulation of the internal areoptimized to ensure that the temperature control is sensitive and the internal and external temperature difference is small.

6) Heating and cooling medium of each barrel can be operatedindependently, as well, the temperature can be controlled independently.

7) Bushing with wear-resistant alloy material, long using life.

Company Introduction

(1) Provide variety models of twin-screw extruders and supporting ingredients, drying, tabling, baking, spraying, frying machines.

(1) Provide variety models of twin-screw extruders and supporting ingredients, drying, tabling, baking, spraying, frying machines.(2) Achieved equipment independent design and production, obtained a number of patents, successfully realized the grains products Extension and promotion of nutrition, rice, breakfast cereals, kinds of fried, non-fried snack foods, high molecular tissue proteins, brush tissue protein, instant porridge, instant rice and other fields. (3) Provide complete food twin-screw extrusion technology engineering demonstration center, it can provide users with a multifunctional scientific research demonstration platform for food production equipment, technology, formula development and application, fully bridge the integration of production, learning and research, function, reduce the investment risk of customers, promote the application of extrusion technology in grain food processing and create value for customers. (4) The scope of participation in food engineering projects

includes the following: it enables us to provide our customers with a complete set of project solutions based on the specific

requirement of our customers, and to propose, plan, design and project food plants to suit your budget and specific production needs.

(5) Complete turnkey system for crushing mixing systems, micro-component dosing systems, extrusion drying systems, and spray coating systems.

(6) Central centralized control system, whole plant automation engineering.

(7) Complete peripheral equipment: electrical installation, automation, pneumatic and liquid applications, civil engineering for turnkey projects.

(8)Application include breakfast cereal cornflakes, ready-to-eat rice nutrition rice series, protein, tissue protein, snack foods,pet food, aquatic feed, etc.

Customer Case

Exhibition

FAQ

(1) Q: What kind of production can be made? A: Corn flakes, Puffs, Breakfast cereals food, Animal feed, Aquatic feed, Soya Texture protein food.

(2) Q: How is the delivery time?

A: Normally 40-45 days, depends on the final production and machine modification.

(3) Q: How about the installation service?

A: Depend on the whole line equipment list, normally needs 2-3 weeks. Will provide the installation

service, like start,operating, inspection machines, testing different formulations.

(4) Q: How is the warranty time?

A:1 Year, for the screw and barrel, due to they are adopted modular design, change the wear part

will be ok,unlike the complete set screw, no need change whole set.

The1year

The1year