- magnetic pump:

- chemical pump

- industrial pump:

- plastic pump

- acid transfer pump:

- corrosion resistant circulating pump

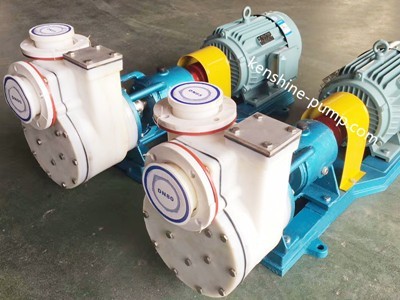

Polypropylene plastic magnetic coupling centrifugal pump (no leakage)

CQF engineering plastic polypropylene corrosion resistant magnetic pump adopts the permanent magnet coupling to transfer torque. When the motor drives the external magnetic steel to rotate, it drives the internal magnetic steel rotor to rotate synchronously through the action of magnetic field, and the internal magnetic steel rotor is connected with the impeller to make the impeller to rotate without contact. The liquid is closed in the static isolation sleeve, so the magnetic pump is a completely closed and has no leakage.

Pump material : RPP polypropylene plastic with good corrosion resistantance)

CQF polypropylene magnetic pump is mainly made of reinforced polypropylene plastic and has good corrosion resistance to most organic and inorganic acid, alkali, salty solutions.

Pump body: RPP (reinforced polypropylene plastic)

Impeller and inner magnetic rotor are molded by RPP for the whole unit

Isolating sleeve is molded by RPP.

Pump shaft: alumina ceramics, SiC etc.

Bearing: high density carbon filled with PTFE

Dynamic ring: PTFE

Static ring: alumina ceramics

Seal ring: FKM, EPDM

Pumped liquids

CQF engineering plastic magnetic pump is widely used to convey acid, alkali, oil etc. rare and precious liquid, venom, volatile liquid, as well as circulating water equipment, filter equipment. CQF magnetic pump is especially suitable for the liquids which is easy to leak, flammable, explosive etc. transportation. The pump driven by the explosion-proof motor is more ideal equipment.

Application

It can be widely used in chemical, pharmaceutical, petroleum, electroplating, food, national defense, scientific research institutions, metallurgy, dye and other units.

Model meaning:

CQF type engineering plastic magnetic pump

CQF 50-25

50- inlet diameter (mm)

CQF- engineering plastic magnetic drive pump

25 - head (m)

| Model | Caliber | Flow (m3/h) | Head (m) | Motor power (kW) | Voltage | |

| Inlet (mm) | Outlet (mm) | (V) | ||||

| 10CQF-3 | 10 | 8 | 0.9 | 3 | 0.01 | 220 |

| 14CQF-5 | 14 | 10 | 1.2 | 5 | 0.12 | 220/380 |

| 16CQF-8 | 15 | 15 | 1.5 | 8 | 0.12 | 220/380 |

| 20CQF-12 | 25 | 18 | 3 | 12 | 0.37 | 220/380 |

| 25CQF-15 | 25 | 20 | 6.6 | 15 | 1.1 | 380 |

| 32CQF-15 | 32 | 25 | 6.6 | 15 | 1.1 | 380 |

| 32CQF-25 | 32 | 25 | 6.6 | 25 | 1.1 | 380 |

| 40CQF-20 | 40 | 32 | 10.8 | 20 | 2.2 | 380 |

| 50CQF-25 | 50 | 40 | 14.4 | 25 | 3 | 380 |

| 50CQF-32 | 50 | 40 | 13.2 | 32 | 4 | 380 |

| 65CQF-25 | 65 | 50 | 25 | 25 | 5.5 | 380 |

| 65CQF-32 | 65 | 50 | 25 | 32 | 5.5 | 380 |

The1year

The1year

FP Polypropylene plastic pump

FP Polypropylene plastic pump

G Single screw pump

G Single screw pump

DBY electric diaphragm pump

DBY electric diaphragm pump

QDLF multistage pump

QDLF multistage pump

CYZ Self-priming oil pump

CYZ Self-priming oil pump

RY thermal oil pump

RY thermal oil pump

RPP-65-280

RPP-65-280

multistage circulation pump

multistage circulation pump

QBK,QBY air diaphragm pump

QBK,QBY air diaphragm pump