- Model NO.:

- STV Series

- Certification:

- CE

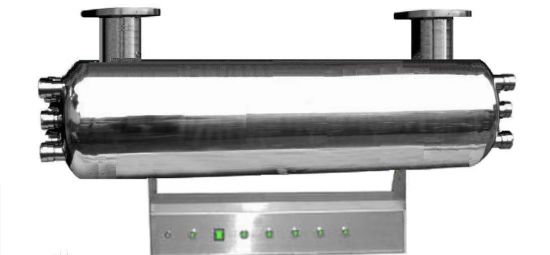

Bioevopeak Hydrogen Peroxide Plasma Sterilizer low temperature Plasma Sterilizer 100/130L/190 L with CE certified

Features

Hydrogen Peroxide Plasma Sterilization are far above the old methods of sterilization like autoclaves, heat sterilizations, which could take hours to processing and have limitation to heat sensitive equipments. Our Plasma Medical Sterilizers can sterilize a wide range of instruments including metal ,plastic ,cable and lens ,which are sterilized by low temperature .

1. Can be easily installed and relocate

2. No special facilities required (Water / vent)

3. Rapid cycle time, No aeration after sterilization, High vacuum pump for deep penetration

4. Processes a wide range of surgical instrument, Compatible with moisture / heat-sensitive materials

5. Environment friendly design, User friendly chamber design

6. Easy to clean and maintain, Easy to use sterilization agent cassette

7. Corrosion & Acid proof housing

8. Thermal printer for complete cycle information

Specifications

| Models | STV-220 | STV-100 | STV-130 |

| Chamber Volume | 190 Liters | 100 Liters | 130 Liters |

| Construction | 5052 Aluminium | ||

| Processing Temperature | Below 55°C | ||

| Control System | Siemens PLC | ||

| Display | 7" Touch Screen | ||

| Printer | Thermal Printer | ||

| Touch Screen Functions | Phase Temperature Date and time Cycle Selected alert message | ||

| Data Storage | Memory Card | ||

| Total Cycle Time | Short cycle 30 minutes , long cycle 50 minutes | ||

| Noise | < 60 db | ||

| Door | One | ||

| Alarm | Door Lock Power Failure Low / High Temp. range Vacuum & Pressure | ||

| Peripheral Devices | Biological Incubator | ||

| Power Consumption | 2.5 KVA | ||

| Power Supply | 220 V, Single Phase 50 Hz | ||

| Mobility | 4 Wheels | ||

| Standards | EN ISO 9001:2016, EN ISO 13485:2016 EN ISO 14001 , EN 61010-2-040, EN 61010-2-042 | ||

Certifications

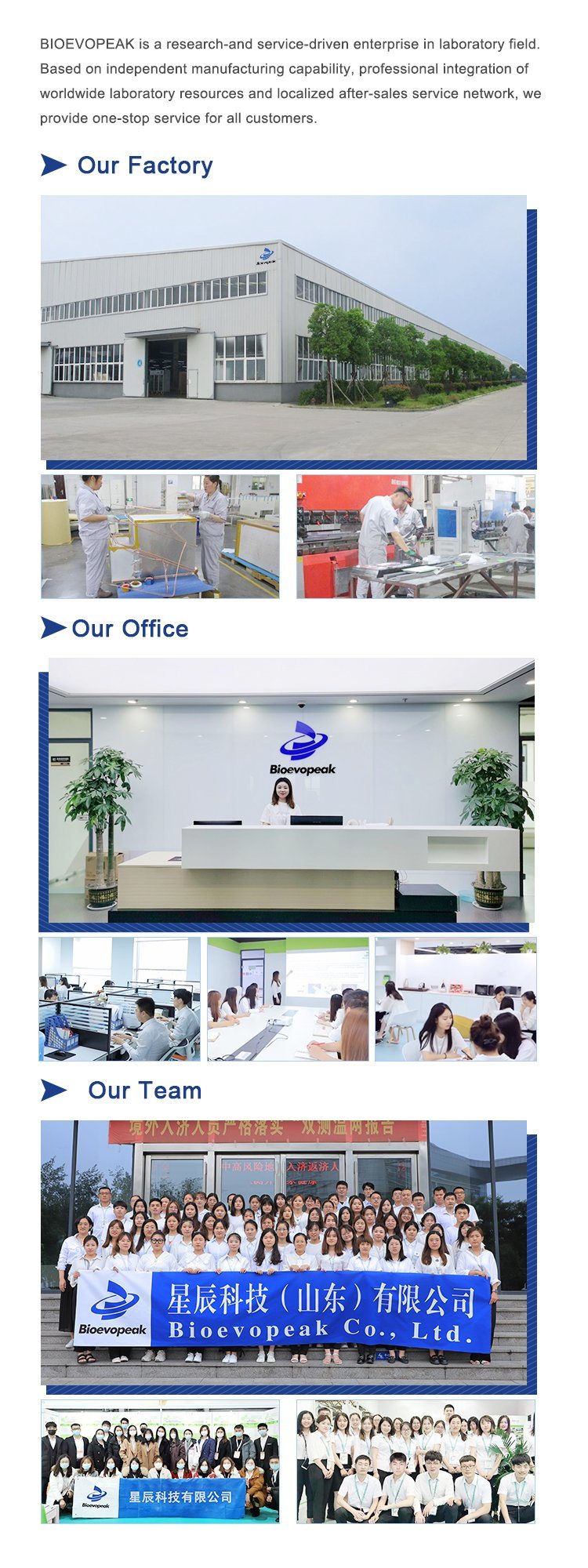

about Us

about Us

Q: How about quality of the goods?

A:

All the running products comply with CE standards.

Independent quality inspection team, conducting multiple inspections and random inspections from parts supply to product dispatch.

Well-known third-party testing service available, such as SGS, BV, and TUV, etc.

Q: What are your pre- and after-sales services?

A:

Timely reply to pre-sales enquiries

Real-time update of manufacturing and shipment status

Contracted third-party maintenance company in over 60 countries

Assured availability of parts supply for 10 years at least

Q: Is OEM service available.

A: Most of the running products are available for OEM customization, including logo, package and function, if attainable, customization.

Q: How long is the lead time:

A: Generally, the lead time for most stocked products is about 7~15 days, vary by models and production schedule. For those non-stocked products, the manufacturing lead time is around 20 days.

The1year

The1year