- Model NO.:

- FST-SIZE

- Certification:

- CE, ISO13485

Company introduction

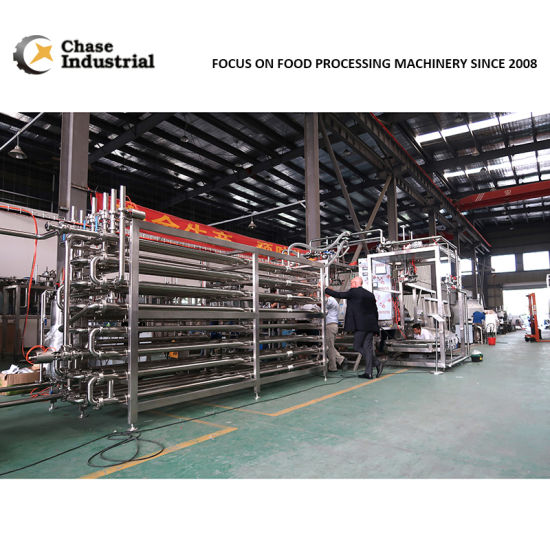

1. Our products include the overall facilities of EO sterilization chamber, the preconditioning chamber, degassing chamber and EO waste gas treatment apparatus.

2. Products meets the requirements of ISO9001:2008 and ENISO134585:2003/AC2009.

3.The only manufacturer of EO sterilization that uses hot air heating system in China, and had applied the "utility model patent certificate".

4. The leading place of ethylene oxide sterilization in China.

5. Have a large number of high quality customers: Jiangsu Fresenius Medical Care (Germany), Nanchang Kelinnike Medical Appliance (Germany), Shenzhen DooJung Group (Korea), Nanjing micro-tech, Winner Medical etc.

6. Products had exported to many countries, such as Spain, South Africa, Ecuador, Laos, Vietnam, Argentian ,etc.

Products photos

The process of E.O. gas sterilize:

1.Put the goods in the sterilizer (Lock the door, make sure it can't be open by anyone else).

2. Temperature Adjusting: Adjust the temperature to the necessary 50ºC, takes about 1~2 hours.

3. Pre-Vacuum: Vacuum the air in the sterilizer, it takes about 6~30 minutes.

4. Air Pressure Holding Test: Checking the tightness of sterilizer, make sure no gas leaks.

5. Pre-humidification: pre-humidify the sterilized goods to 55%RH humidity, it takes 1-1.5 hours.

6. Inject EO gas into the chamber: 20- 30 minutes

7. E.O. Sterilizing: make sure every condition is not changed, keep it 4 - 8 hours.

8. Sterilization finishes: clear the residue E.O. gas. Vacuum degree 60 Kpa. Blow Air inside, repeat at least 3 times. It takes about 1 hour.

9. Unlock and open the door, pull the cart outside the sterilizer.

Our sterilizer chamber can sterilize two batch of cargos in 24 hours.

The Process of Ethylene Oxide Sterilization:

1. preconditioning stage

2.sterilizing stage

3.degassing stage

4.waste gas treatment

EtO Gas Sterilizerspecifications

| TechnicalInfo. | Specifications |

| MachineType | EthyleneOxidesterilizers/Sterilizationchambers |

| ChamberCapacity | 1to100 m3 |

| ChamberType | Rectangulartype,1to13pallets(80x120cm) insingleordoublerows |

| DoorsType | Doubledoorswithpneumaticslidingsystems (ManualandAutomaticcontrol) |

| ChamberMaterial | Stainlesssteelconstructioninchamber (grade304or316) |

| HotwaterCirculation | Doublejacketwith4circulationssystemsofhotwater doorsandchamber.Pumpsandwatertankintegrated |

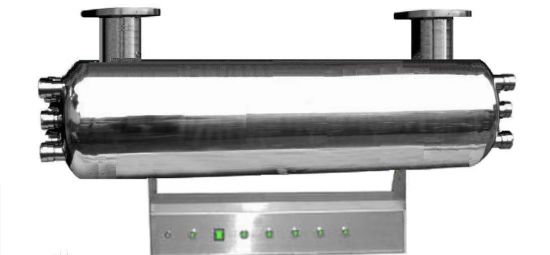

| SteamGenerator | Steamgeneratorwithtank |

| Filtration | Watertreatmentbyfiltrationsystem |

| ETOVaporizer | Ethyleneoxidevaporizer |

| ETOCirculation | ETOcirculationsystem(ATEXcirculationpump) |

| PneumaticEnergie | Aircompressor |

| ElecticEnergie | 380AC,50Hz or 60HZ |

| Software/Controls | |

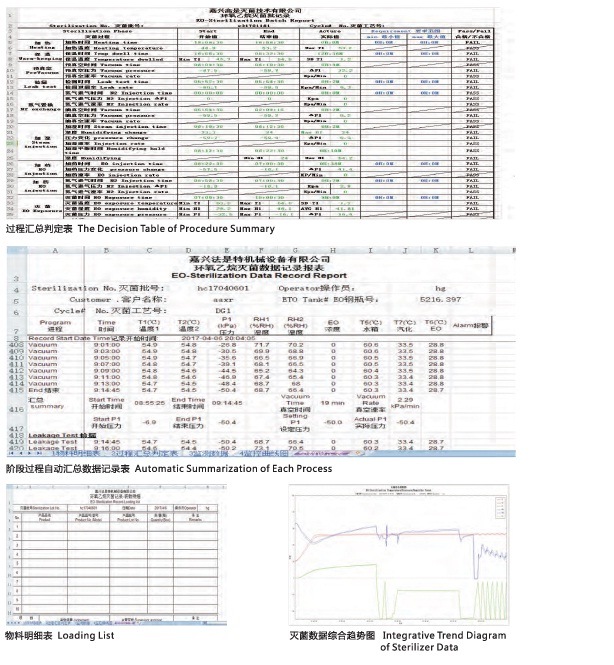

| Software/controls | Software:Automaticandmanualcontrol,datastorage,graphic recorder(temperature,humidity,pressure,time,cyclesteps…). Safetypasswordadministrationandoperator. |

| PLC | SIEMENSorSCHNEIDERProgrammableLogicController |

| Sensors | Pressure,temperature,humiditysensors |

| Computer | Computerwithprinteranddesk |

| Options(systems) | |

| Sensors | EX/ATEXsensors |

| Nitrogengenerator | Nitrogengenerator |

| MaintenanceService | ExtraServicesaftersales |

| Software | SoftwarequalifiedFDA21CFRpart11 |

The1year

The1year

Medical Instrument Ethylene Oxide

Medical Instrument Ethylene Oxide

Syringe Sterilization Machine Ste

Syringe Sterilization Machine Ste

Dental Equipment CE Standards Eo

Dental Equipment CE Standards Eo