- Model NO.:

- Certification:

- CE, ISO13485

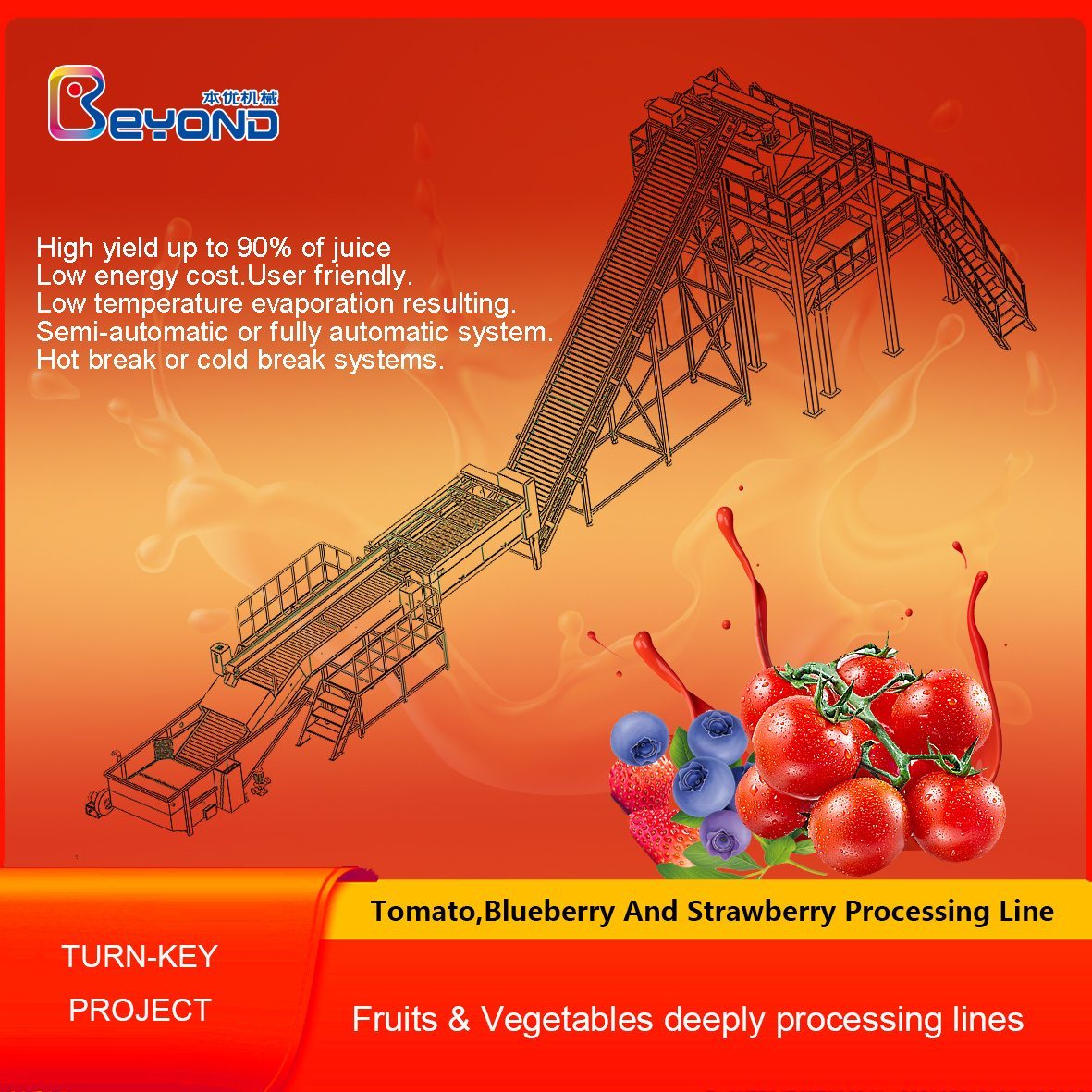

High Quality Fruit Juice Processing Blueberry juice processing machine

Describe

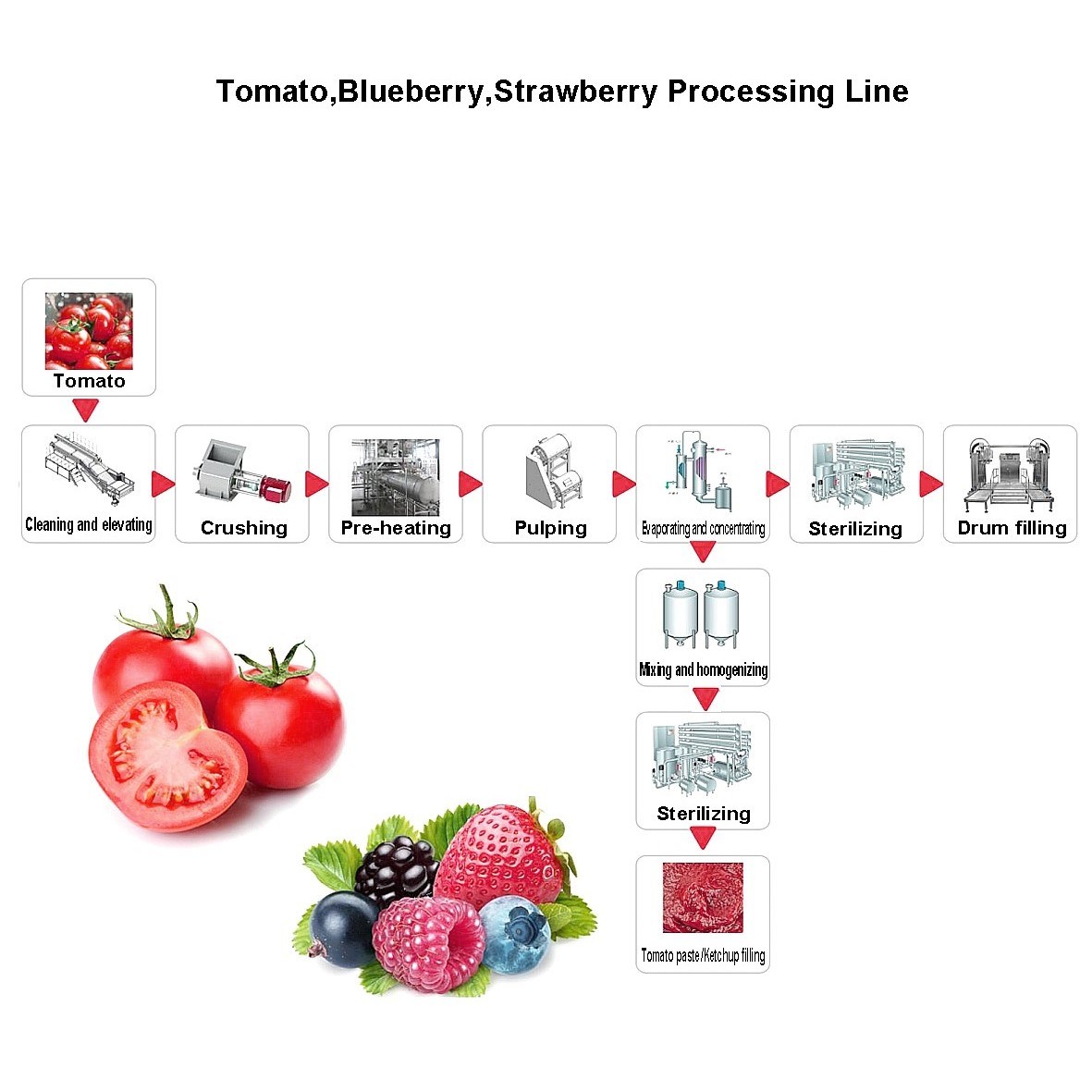

The blueberry candied fruit production line is made of fresh blueberry fruit as raw material through the processes of fruit production, washing, peeling / nucleating / slicing / cutting, precooking, dehydration, vacuum sugar infiltration, drying, finishing and packaging. The food has bright and transparent color. The surface is dry, slightly sticky, and the water content is less than 20%.

Application of blueberry preserves production line:

Blueberry preserves production line is applicable to all kinds of preserved fruits, including apple preserves, apricot preserves, pear preserves, peach preserves, Taiping preserves, green plum, hawthorn slices, peel, etc.

The main equipment includes: washing machine, fruit and vegetable peeling machine, slicing and coring machine, vacuum sugar infiltration system, continuous precooking machine, drying oven, etc. Through the above equipment, the full mechanized production of preserved blueberry fruit can be realized.

Blueberry preserves production line

Picking belt: used for manual picking of insect eyes and rotten blueberries;

Washing machine: bubble washing machine is mainly used for cleaning blueberry fruits;

Alkali peeling machine: the equipment has strong processing capacity and good peeling effect. Blueberry pulp has no wear and scar, high yield, saves lye and reduces workers' labor intensity. The running speed of the conveyor belt is adjustable and the equipment operates reliably.

Semi cutting coring machine: optional according to specific materials;

Continuous pre boiling machine: blanching and blanching through the blanching machine can effectively inhibit the enzyme activity in fruits and vegetables, so as to maintain the unique fresh color of fruits and vegetables, maintain the original flavor of blueberries, increase the softness of cells and promote water evaporation. The process requirements laid a good foundation for the next drying and dehydration process.

Mesh belt dewatering: drainage through mesh belt vibration;

Vacuum sugar infiltration system: the equipment adopts the advanced vacuum impregnation principle, which greatly shortens the processing time of blueberry preserves, ensures the hygiene and safety of the production process, and effectively improves the work efficiency. It is an ideal equipment to replace the traditional sugar soaking process and rapid process.

Dryer: dry the sugar soaked blueberry fruit;

Packaging machine: replace manual packaging with bag packaging machine to realize the packaging automation of large enterprises and small and medium-sized enterprises.

Machine list withTechnical parameter

| No | Code | Equipment Name | capacity | Parameter |

| 1 | A . fresh fruit(tomato) washing unit | |||

| 2 | A-1 | Clapboard elevator | 6T/h | Height * width: 5500*1000, motor of 2.2KW and adjustable geared motor 20~100RPM, pitch 38.1 anti-corrosion roller chain |

| 3 | A-2 | air-blow washer and sorting machine | 6T/h | stainless steel centrifugal pump ; oxygen pump; lifting speed can be adjustable,size of elevator and sorting roller platform is φ51, sorting table with guardrail, platform is made of stainelss steel anti-skidding checkered plates |

| 4 | A-3 | Clapboard elevator | 6T/h | motor 2.2KW and speed reducer 20~100RPM, stainless steel plate, 4500 x 1000mm |

| 5 | subtotal: | |||

| 6 | B. Pulping unit | |||

| 7 | B-1 | Crusher | 6T/H | SUS304, power is about: 18.5KW |

| 8 | B-2 | Tempoary storage tank | 1000L | SUS304, single, installed on the top of the lamp hole mirror, CIP cleaning ball, bottom flange type outlet, with low level, four adjustable legs |

| 9 | B-3 | Screw pump | 6T/H | Manual speed control, outlet pressure 0.6Mpa |

| 10 | B-4 | Tubular heat exchanger heater | 6T/H | Food sanitation, tube heating , with the inlet steam pressure system, automatic control temperature with a outlet thermometer, |

| 11 | B-5 | Double beater | 6T/H | SUS304, first mesh 0.8mm , secondary mesh 0.4mm, power 37KW |

| 12 | B-6 | Buffer storage tank | 1000L | SUS304, single, circular, half open, bottom flange outlet, high and low level, pure water inlet |

| 13 | B-7 | Screw pump | 6T/H | Manual speed control, outlet pressure 0.6Mp |

| 14 | B-8 | crusher platform | carbon steel frame, stainless steel checkered plate, size: 5000mm×2500mm, central draining | |

| 15 | B-9 | pulping operation platform | Carbon steel bracket,stainless steel checkered plate, size:3500mm×2500mm, central draining | |

| 16 | Subtotal | |||

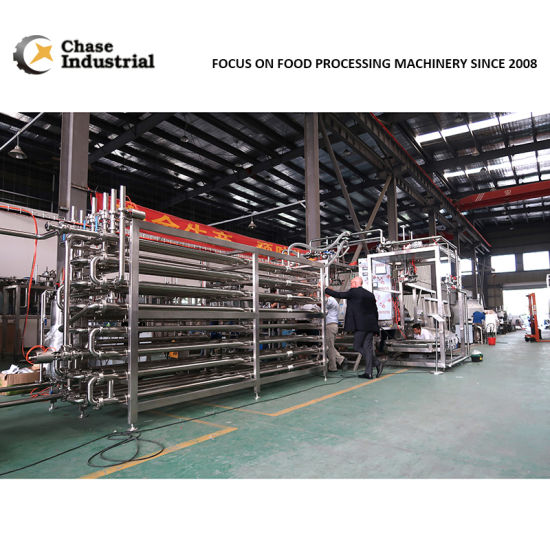

| 17 | C .Evaporator and concentrating unit | |||

| 18 | C-1 | Buffer storage tank | 5000L | SUS304, PU insulation, conical head, pull rod valve at bottom discharge , sealed manhole, ladder,high and low level, sampling valve, the top offset vertical mixing, anti-vortex plate, digital thermometer, CIP cleaning ball, adjustable support legs |

| 19 | C-2 | Centrifugal pump | 10T/H | Food grade, mechanical seal, ABB motor, 36M lift |

| 20 | C-3 | Double-effect forced circulation evaporator | 4T/H | SUS304, automatic PLC control, the British Spirax Sarco steam pressure regulating valve system, inlet temperature sensor, pressure sensor, tower water cooling. |

| 21 | C-4 | Batch storage tank | 5000L | SUS304, single layer, digital thermometer, sampling valve, sealed manhole, ladder, top offset vertical mixing, high and low liquid level sensor, adjustable legs |

| 22 | C-5 | Rotor pump | 3T/H | Food grade rubber seal, variable frequency speed regulation |

| 23 | Subtotal | |||

| 24 | D. Sterilizing and filling system | |||

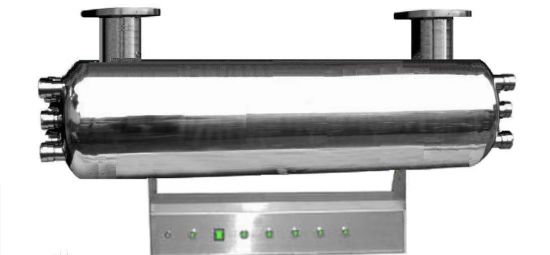

| 25 | D-1 | Tube-in-tube UHT sterilizer | 1T/H | SUS304, Tube-in-tube type, automatic PLC control, tower water cooling , the British Spirax Sarco steam pressure regulating valve, sterilization temperature 110 ºC, 60S |

| 26 | D-2 | Filling machine | 1T/H | |

| 27 | Subtotal | |||

| 28 | E CIP system | |||

| 29 | E-1 | Semi automatic single circuit CIP | 2T×3 | SUS304 outer cladding, inner shell SUS316, 3000L acid and alkali tank, 3000L hot water tank, coil tube heating inside the tank, automatic temperature control, single circuit, United States of America concentrated acid and alkali adding system, with two 200L concentrated acid and alkali tank, 2pieces of centrifugal pump (20T/h, head of 24m) |

| 30 | R | CIP return pump | 20T/H | Food grade, self-sucking, mechanical seal |

Characteristics of blueberry preserves production line:

1. In addition to blueberries, it can also process apples, pears, peaches, apricots, mulberry, bananas, tomatoes and other fruits and vegetables. One machine can be used for multiple purposes;

2. It can produce dried fruits and vegetables, fruit and vegetable slices, various crisps, etc. the configuration of the production line is flexible, and it can meet the different final product needs of customers;

3. It can process dried fruits and vegetables and potato chips of different shapes and sizes. The whole line adopts modular design and different processing technologies;

4. High degree of automation, labor-saving, with cleaning system, convenient cleaning;

5. The material contact part of the system adopts 304 stainless steel, which fully meets the requirements of food hygiene and safety;

Company Profile

Our Service

Trade shows

Certificate

FAQ

1 ) Q: How can we visit your factory?

A: If you come from abroad, air to shanghai airport, then we can pick you up at airport.

2) Q: How do you ensure the quality of your products?

A: Our Company is a state owned enterprise with more than 16 years experience , strict operation policy is performed, advanced processing machines guarangtee the precision of all components, workers with operation license, parts get multiprocessing, transmission& electrical parts are of international famous brand. Series of test and inspection are done in the whole producing state.

3) Q: What payment methods your company accept?

A: We accept most of the payment methods , but mainly accept T/T, L/C at sight .

4) Q: How long is the warranty time for your products?

A: Our officially promised warranty time is 12 months after commissioning .

5) Q: I am new in this field,can you supply us turnkey services?

A: YES.We can supply all the system including Market Analysis/Product Analysis/Location Choice/Processing Flow Design/Equipment Layout Design/Building Design direction/Equipment mode selection/Equipment Manufacturing/Equipment Mounting/Equipment Debugging/Worker Training.

6) Q: What ' s the shipment terms and delivery time of your company?

A: Well, the delivery time depend on the quantity of your order. Usually is 20 days . For some customized machine 30 days is necessary.

7) Q: Can you supply OEM services?

A: Yes,we have our R&D team,and we have more than 400 workers with workshop area 75000 square meters.

8) Q: Do you give any Discount?

A: I will surely try my best to help you get those by the best price and good service at the same time.

The1year

The1year