- Model NO.:

- DN500~DN1300 autoclave

- Certification:

- CE

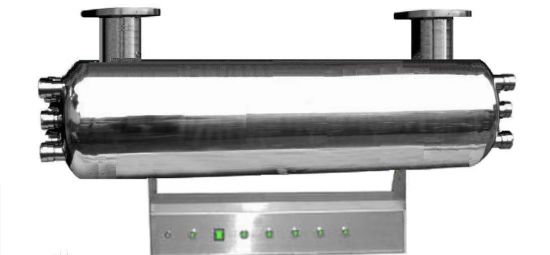

vertical cooking pot | vertical pressure cooker

Horizontal autoclave

WORK PROCESS FLOW:fill water into the water tank and loading the products into the chamber.Start to heating the water in the water tank, heat to a suitable temperature.Transfer hot water from the water tank into the sterilizer chamber and start to sterilization process. This step will keep about 20 to 35 mins according to your product.hot water was collected into the water tank ( will used to next batch ) after sterilization.Fill cool water into the chamber to cool the temperature down and than discharge the water, then fill in and discharge twice.Finished this batch and unload the sterilized product. Heat the water in water tank and prepare the next batch. The total time for one batch is about 1 hour.

HOT SELL AUTOCLAVE LIST AND MAIN SPECIFICATIONS

| Product | Detail | Qty | Unit price |

| DN900×1500 Autoclave | MANUAL CONTROL Made of SS304, Single wall, with pipe and fittings With pump, with one pair of basket and dolly | 1 | |

| SEMI-AUTOMATIC CONTROL With insulated retort body With insulated water storage tank With insulated retort body With automatic steam control valve With one pair of basket and 2 dollies | 1 | ||

| Basket for DN900×1500 | 750*....mm 2 pcs such baskets in each pair | 1 pair | |

| DN1100×2000 Autoclave | MANUAL CONTROL Made of SS304, single wall With pipe and fittings, with pump. With one pair of basket and dolly | 1 | |

| SEMI-AUTOMATIC CONTROL With insulated retort body With insulated water storage tank With insulated retort body With automatic steam control valve With one pair of basket and 3 dollies | 1 | ||

| Basket for DN1100×2000 | 680*7..... 3pcs such baskets in each pair | 1 pair | |

| Paperless recorder | Local brand | 1 | |

| PLC controller A | PLC control system, use Siemens touch screen All electric parts use world famous brand Use stainless steel cover | 1 | |

| PLC controller B | Local brand electric part and touch screen |

The1year

The1year