- Model NO.:

- 50L

- Certification:

- CE, ISO9001

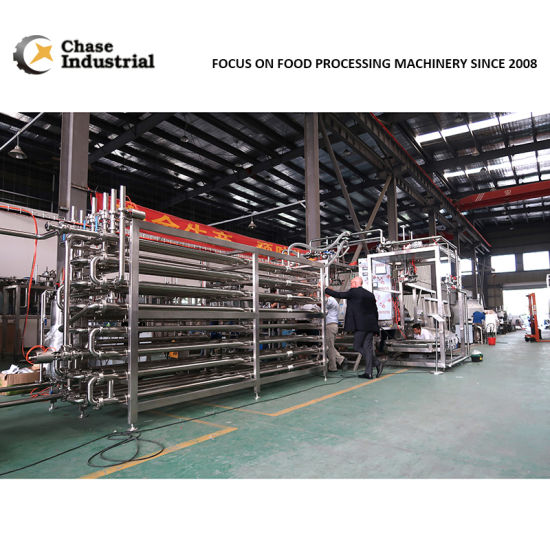

This Milk pasteurizing machine is mainly used for disinfection of fresh cow milk,yogurt,sheep milk,camel milk,juice, beverage and other dairy products sterilization, but also can be used in beer, egg liquid, honey,milk and other liquid sterilization.The main principle is the principle of pasteurization,that is,low-temperature sterilization,which is not more than 100 °C to milk sterilization,pasteurization to retain the beneficial bacteria in milk at the same time,exterminate harmful bacteria such as E.coli.

Sterilization tank with insulation facilities and a temperature compensation device,effectively ensuring the balance of water temperature inside the tank to ensure sterilization effect.

What isPasteurization

Pasteurization,also known as Pasteurisification (French: Pasteurisation),French biologist Louis Pasteur (LouisPasteur) invented in 1862 sterilization method,mainly for milk,kill the milk contains Bacteria do not affect the taste of milk itself.Pasteurization (pasteurization),also known as low temperature disinfection, cold sterilization method,resulting from Pasteur to solve the problem of beer acid problem.Is a use of lower temperature can kill the bacteria and can keep the nutrient substances in the same flavor of the disinfection method. Is often used broadly to define the heat treatment methods that require killing of various pathogens.

Using a lower temperature (usually 60 ~ 82 ºC),within a specified period of time, the food heat treatment,to kill the purpose of microbial nutrition,is a both to achieve the purpose of disinfection and not damage the quality of food methods.By the French microbiologist Pasteur named after the invention. Pasteurization heat treatment is relatively low,generally lower than the boiling point of water temperature heating,heating medium for hot water.

Features

1.This milk pasteurizer is made of high quality SUS304 stainless steel material, and its sterilization temperature and speed can be set according to the technical requirement.

2.Milk tank is divided into three layers. The most outer layer is the thermal insulation layer, and the middle is hot water sterilization layer, the inner layer is for milk.

3.Our milk pasteurizer has the agitator, so the milk can be heated evenly. Also there is a thermameter which can show you the temperature during pasteurizing.

4.Sterilization time is 5-40 minutes and can adjustable; sterilization temperature is 50-99Cwith automatic temperature control device.

5.The water temperature of milk sterilization tank is between 65 ° ~ 90 °, not only can play a bactericidal effect, but also ensures that the protein and other nutrients not change over a wide temperature range, keeping the original quality of milk, flavor, color etc., to make the effect that the food without any preservatives, is conducive to the health of consumers.

6.Sterilization tanks have a holding facilities and a temperature compensation device, to ensure the inside temperature of balance effectively ,and sterilization effect.

Technical parameters

Single milk pasteurizer barrel

| Model | 50 | 70 | 100 |

| Volume | 50L | 70L | 100L |

| Production | 50kg/time | 70kg/time | 100kg/time |

| Material | SUS304 | ||

| Sterilization time | 0~30min ( adjustable ) | ||

| Sterilization Temperature | 65-95(Adjustable) | ||

| Power | 5 | 6 | 7 |

| Dimension | 570x500x1010mm | 680x570x1150mm | 770x600x1310mm |

| Cooling type | Water cooling | ||

Milk pasteurizer with water cooler type

| Model code | W100 | W150 |

| Capacity/volume | 100L/batch | 150L/batch |

| Material | 304 stainless steel | |

| Power | 6KW | 9KW |

| Sterilization | Time:0-30minutes(adjustable) | |

| Temperature:75-95C(adjustable) | ||

| Size | 1200*800*1300mm | 1200*800*1500mm |

| Cooling | Water cooling | |

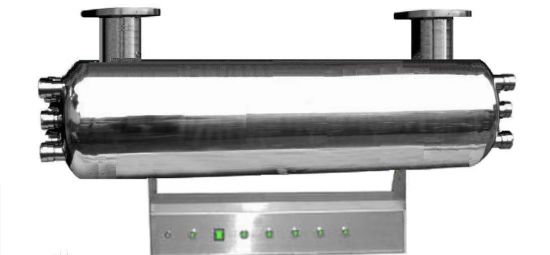

Structure diagram

Structure diagram

Machine details

The1year

The1year