- Model NO.:

- customization

- Certification:

- CE

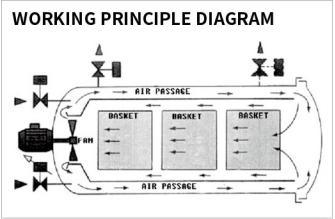

The steam-air retort does not need phase of exhausting the cold air in retort ,and breaks the temperature and pressure corresponding law under the saturated steam to realize the flexible pressure control of the steam sterilization process.

Flexible packaging, bottled, tinplate cans (canned luncheon meat, canned tuna, etc.), standing bags, aluminum foil boxes, cups and bowls of snack foods, meat products, beverages and other high-temperature sterilization products.

Main Feature

1.Compressed air is injected into the retort, and the turbo fan rotates to break the cold air mass, The mixture of steam and air is forced to circulate in the retort,for thorough sterilization and saving over 15% steam;

2. With dual pressure & temperature sensors and over pressure&temperature alarm function,it can better protect equipment and products;

3. Flexible control of pressure and temperature,realize cooling with counter pressure.

Accurate temperature control, excellent heat distribution

The temperature control module has up to 12 stages of temperature control, and the step or linearity can be selected according to different products and process recipe heating modes, so that the repeatability and stability between batches of products are maximized well, the temperature can be controlled within ±0.3ºC. Steam enter the chamber while circulating fans ensures a proper temperature in the chamber. Sterilization is carried for preset temperature level & time.

Rapid heating

No need to heat other media (such as hot water), the heating rate is very fast.

Perfect pressure control, suitable for a variety of packaging forms

The pressure control module continuously adjusts the pressure throughout the whole process to adapt the internal pressure changes of the product packaging, so that the degree of deformation of the product packaging is minimized, regardless of the rigid container of tin cans, aluminum cans or plastic bottles, plastic boxes or flexible containers can be easily satisfied, and the pressure can be controlled within ±0.05Bar.

Save energy saving and protect environment

The steam is directly heated, no exhaust is needed, and the minimum steam loss.

Low noise, create a quiet and comfortable working environment.

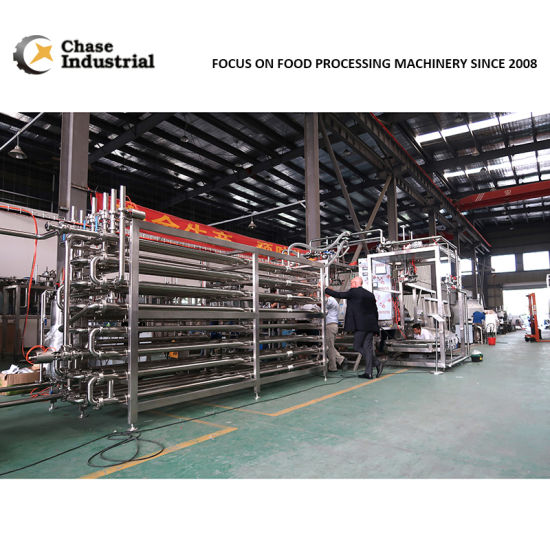

SHANDONG INCHOI MACHINERY CO., LTD.Isa global supplier specializing in the Food&Beverage industry equipment. We focuses on the research and development, sales, manufacturing, engineering installation and after-sales of quick-freezing whole line equipment such as pasta, seafood, fruits and vegetables, and meat preparations Services, to provide customers with a complete set of equipment solutions.Company consists of fruit&vegetable processing department, vacuum packaging department, and automated sterilization department. The technical team is composed of engineers with more than 20 years of experience in the food industry.

The main products include IFQ Freezer, thermal forming vacuum packing machine,retortand complete set of automatic loading and unloading sterilization production line,vacuum frying machine, French fries and all kinds of crispy chips frying line, fruit and vegetable cleaning and processing drying lineand other equipment sales and manufacturing. The company's products have passed CE certification and ISO9001-2000 international quality management system certification, and meet the QS standards of food enterprises.

In 2019, the company established a joint RESEARCH and development center with Singapore company-P Control Technology Pte Ltd.in 2Yishun Industrial St1.North Point Bizhub, dedicated to the research and development and application of frozen Technology and high-end automation equipment.In 2021, LOO YEOW TECK, legal representative of Singapore Company, withShandong INCHOIMachineryCO., LTD.invested and established LonGRISE (SHANDONG) INTELLIGET EQUIPMENT CO., LTD. in Zhucheng city ,Further expand domestic production bases and export to the world.

After years of hard work and innovation, the company has established offices in Southeast Asia, the Middle East, Africa, Eastern Europe, and South America, and the equipment has been exported to the United States, Russia, Italy, Spain, Romania, Algeria, Thailand, Vietnam, Singapore, Indonesia, Chile, Ecuador and other countries. It has a global service level, has steadily improved in the industry, and has won praise from many experts.

The company adheres to positive research and development, and continuously absorbs the most advanced technology at home and abroad and has reached the beginning to keep pace with the world. The company has successively established training bases with many colleges and universities, and through continuous innovation and absorbing talents, INCHOI can make better products for the benefit of mankind. INCHOI Intelligent has always adhered to the great dream of "striving for the world's food industry for a lifetime", taking customers as the center and creating a better future together!

The1year

The1year