- Model NO.:

- HTAJ

- Certification:

- CE, FDA, EEC, ISO13485

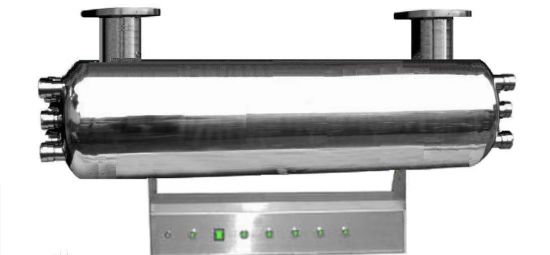

Ethylene oxide sterilizer

HTAJ2 series ethylene oxide sterilizer is alow temperature sterilization equipment HTAJ2 series large-scale ethylene oxide sterilizer is akind of low-temperature sterilization equipment: This product is designed by using advanced computer technology, automation technology, welding technology and process on the basis of absorbing the advantages of similar products domestic and overseas.

Technical Description of Ethylene Oxide Sterilizer

Air replacement

Automatic ventilation, air exchange frequency and interval can be set freely

Automatic control system

One-click start to end, the whole process is automatically completed with print record

Display status

Display temperature, humidity, pressure, sterilization time, residual gas treatment time, number of times

Printer

The whole process of sterilization information record printing, in order to verify the check.

Humidity sensor

The built-in humidity sensor automatically detects the humidity in the cavity to ensure that the humidity in the cavity is not lower than 45% RH.

Pressure sensor

The inner pressure sensor automatically detects the pressure inside the cavity to ensure the accuracy and efficiency of the pressure.

Temperature sensor

The built-in temperature sensor automatically detects the cavity temperature to ensure that the cavity temperature remains within the accurate range of 50 ºC ±3 ºC.

Humidifying system

Pulse humidification in the vacuum state ensures that the humidity in the cavity is uniform and controllable, and the humidity of the sterilizing chamber should be controlled within the range of 45- 80% relative humidity.

Residual gas treatment unit

Filtration efficiency of filter for particle diameter ≥0.3 μm,not less than 99.5%.

[Sterilization chamber leakage rate

The leakage rate is measured under the condition of no-load and sterilization room temperature, the

test pressure is -50kPa, and the measurement time is 1h.

[Vacuum rate]

Under no-load conditions, the time for the disinfection cabinet to reach -60kPa from normal

pressure should be ≤30min.

[Vacuum system]

The oil-free vacuum pump is used, which is simple and convenient, the vacuum rate is fast, and the

service life is long.

[Heating system]

It adopts explosion-proof electric heating device, which is more convenient and quick

[Tray rack] Use 304 stainless steel tray rack.

[Sterilization chamber leakage rate]

With over-voltage and over-temperature protection function, it is more safe and reliable.

[Casters] Yes.

[Alarm system]

There is ahigh temperature alarm system and an ultra-low pressure alarm system; when the

disinfection temperature of the disinfection room exceeds 59 °C, it should be able to sound an

alarm.

[Category] Class II medical instruments

.

Application:

Hysteroscopy, Laparoscopy, Laryngoscope, Probe, Rigid Endoscope, Hose Endoscope, Ophthalmic Lens, Fiber Optic Cable, Cranial Pressure Sensor, Cold Therapy Probe, Prostatectomy Device, Esophageal Dilator, Electrocautery Devices, defibrillation electrodes, laser head metal, glass, silicone, Chinese medicine and western medicine, human implants, masks, DNA, etc.

(1)Installation requirements of ethylene oxide sterilizer:

1)The ethylene oxide sterilizer must be placed in awell-ventilated place, and it must not be placed near afire source.

2)In order to facilitate repair and regular maintenance, 51cm space should be reserved on each side (including the top) of the ethylene oxide sterilizer.

3)Special exhaust pipes should be installed and completely isolated from other exhaust pipes of the building.

(2)Ethylene oxide safety protection principles and precautions:

1) Keep ethylene oxide sterilizers and cylinders or cans away from sources of ignition and static electricity.

2) Ethylene oxide storage should be free of ignition sources, no rotating motor, no sun, good ventilation, and the temperature is lower than 40 ºC, but it should not be placed in the refrigerator. Dispose of in strict accordance with the relevant national storage requirements for flammable and explosive materials.

3) Do not use too much force when administering or opening the bottle, so as not to spray the liquid.

4)Monitor the air concentration of the ethylene oxide working environment every year.

5)Ethylene oxide staff should be trained in expertise and emergency management.

Contact :

Mandy

The1year

The1year