- chemical pump:

- industrial pump

- transfer pump:

- circulation pump

- acid pump:

- submerged corrosion resistant pump

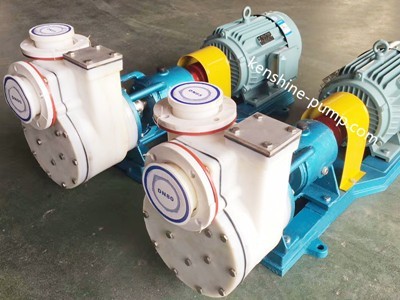

FYS Corrosion resistant submerged pump is the developed single stage single suction long shaft submerged pump with vertical structure. The flow parts for FYS corrosion resistant submerged pump is made of fluorine plastic alloy and the lower protection sleeve is made of silicon carbide with high quality.

FYS corrosion resistant submerged pump is suitable to transport corrosive liquids without solid particles and the temperature of liquids is at 0 to 120 degree Celsius.

FYS corrosion resistant submersible pump has the good corrosion resistance and abrasion resistance. The pump body and impeller are partly immersed into the liquid. So the pump occupies a small area and the shaft seal has no leakage. The liquid level must be higher than 180mm above the central line of the impeller. The pump should be started according to the direction indicated and can not be reversed.

50FYS-25

50 means pump inlet diameter(mm)

FY means corrosion resistance submerged pump

S means the pump material is for fluorine plastic alloy

25 means Head

Performance range:

Flow rate:2 to 460m3/h

Head:3-60m3/h

Pump material: fluorine plastic alloy

Data sheet:

| Model | Speed (rpm) | Flow (m3/h) | Head(m) | Motor power (KW) | Pump outlet (mm) |

| 25FYS-6 | 2900 | 1.2 | 7 | 0.37/0.55 | 20 |

| 1.5 | 6 | ||||

| 2.5 | 5 | ||||

| 25FYS-16 | 2900 | 1.5 | 17.5 | 0.55/0.75 | 20 |

| 2.5 | 16 | ||||

| 3.5 | 14.5 | ||||

| 32FYS-20 | 2900 | 3.5 | 22 | 1.1/1.5 | 25 |

| 5.5 | 20 | ||||

| 7.5 | 16 | ||||

| 40FYS-20 | 2900 | 5 | 22 | 1.5/2.2 | 32 |

| 7.5 | 20 | ||||

| 10 | 16 | ||||

| 1450 | 2.5 | 5.5 | 0.37/0.55 | ||

| 3.75 | 5 | ||||

| 5 | 4 | ||||

| 50FYS-25 | 2900 | 12 | 28 | 3/4 | 40 |

| 17 | 25 | ||||

| 25 | 16 | ||||

| 1450 | 6 | 7 | 0.75/1.1 | ||

| 8.5 | 5 | ||||

| 12.5 | 4 | ||||

| 50FYS-50 | 2900 | 7.5 | 52 | 5.5/7.5 | 32 |

| 12.5 | 50 | ||||

| 15 | 48 | ||||

| 1450 | 3.75 | 13 | 1.1/1.5 | ||

| 6.3 | 12.5 | ||||

| 7.5 | 12 | ||||

| 65FYS-20 | 2900 | 15 | 21.5 | 4/5.5 | 50 |

| 25 | 20 | ||||

| 30 | 18.5 | ||||

| 1450 | 7.5 | 5.3 | 1.1/1.5 | ||

| 12.5 | 5 | ||||

| 15 | 4.5 | ||||

| 65FYS-32 | 2900 | 15 | 34 | 5.5/7.5 | 50 |

| 25 | 32 | ||||

| 30 | 30 | ||||

| 1450 | 7.5 | 8.5 | 1.5/2.2 | ||

| 12.5 | 8 | ||||

| 15 | 7.5 | ||||

| 65FYS-50 | 2900 | 15 | 53 | 7.5/11 | 40 |

| 25 | 50 | ||||

| 30 | 47.5 | ||||

| 1450 | 7.5 | 13 | 2.2/3 | ||

| 12.5 | 12.5 | ||||

| 15 | 11.5 | ||||

| 80FYS-20 | 2900 | 30 | 23 | 5.5/7.5 | 65 |

| 50 | 20 | ||||

| 60 | 17 | ||||

| 1450 | 15 | 6 | 1.1/1.5 | ||

| 25 | 5 | ||||

| 30 | 4 | ||||

| 80FYS-32 | 2900 | 30 | 36 | 7.5/11 | 65 |

| 50 | 32 | ||||

| 60 | 28 | ||||

| 1450 | 15 | 9 | 1.5/2.2 | ||

| 25 | 8 | ||||

| 30 | 7 | ||||

| 80FYS-50 | 2900 | 30 | 55 | 15/18.5 | 50 |

| 50 | 50 | ||||

| 60 | 45 | ||||

| 1450 | 15 | 13.5 | 3/4 | ||

| 25 | 12.5 | ||||

| 30 | 11 | ||||

| 100FYS-20 | 2900 | 60 | 24 | 11/15 | 80 |

| 100 | 20 | ||||

| 120 | 16 | ||||

| 1450 | 30 | 6 | 2.2/3 | ||

| 50 | 5 | ||||

| 60 | 4 | ||||

| 100FYS-32 | 2900 | 60 | 36 | 15/18.5 | 80 |

| 100 | 32 | ||||

| 120 | 28 | ||||

| 1450 | 30 | 9 | 3/4 | ||

| 50 | 8 | ||||

| 60 | 7 | ||||

| 100FYS-50 | 2900 | 60 | 56 | 18.5/22 | 65 |

| 100 | 50 | ||||

| 120 | 44 | ||||

| 1450 | 30 | 14 | 5.5/7.5 | ||

| 50 | 12.5 | ||||

| 60 | 11 | ||||

| 125FYS-50 | 2900 | 120 | 61 | 37/45 | 100 |

| 200 | 50 | ||||

| 240 | 41 | ||||

| 1450 | 60 | 15 | 7.5/11 | ||

| 100 | 12.5 | ||||

| 120 | 10 | ||||

| 150FYS-20 | 1450 | 120 | 24.5 | 18.5/22 | 125 |

| 200 | 20 | ||||

| 240 | 15 | ||||

| 200FYS-20 | 1450 | 240 | 23 | 37 | 150 |

| 400 | 20 | ||||

| 460 | 18 |

The1year

The1year

QBK,QBY air diaphragm pump

QBK,QBY air diaphragm pump

End suction centrifugal pump

End suction centrifugal pump

YG Vertical pipeline oil pump

YG Vertical pipeline oil pump

3GR three-spindle screw pump

3GR three-spindle screw pump

DBY electric diaphragm pump

DBY electric diaphragm pump

multistage circulation pump

multistage circulation pump

ZS l single stage water pump

ZS l single stage water pump

MPH Plastic magnetic pump

MPH Plastic magnetic pump

CZ Chemical process pump

CZ Chemical process pump