- Model NO.:

- HK

- Certification:

- CE, ISO13485

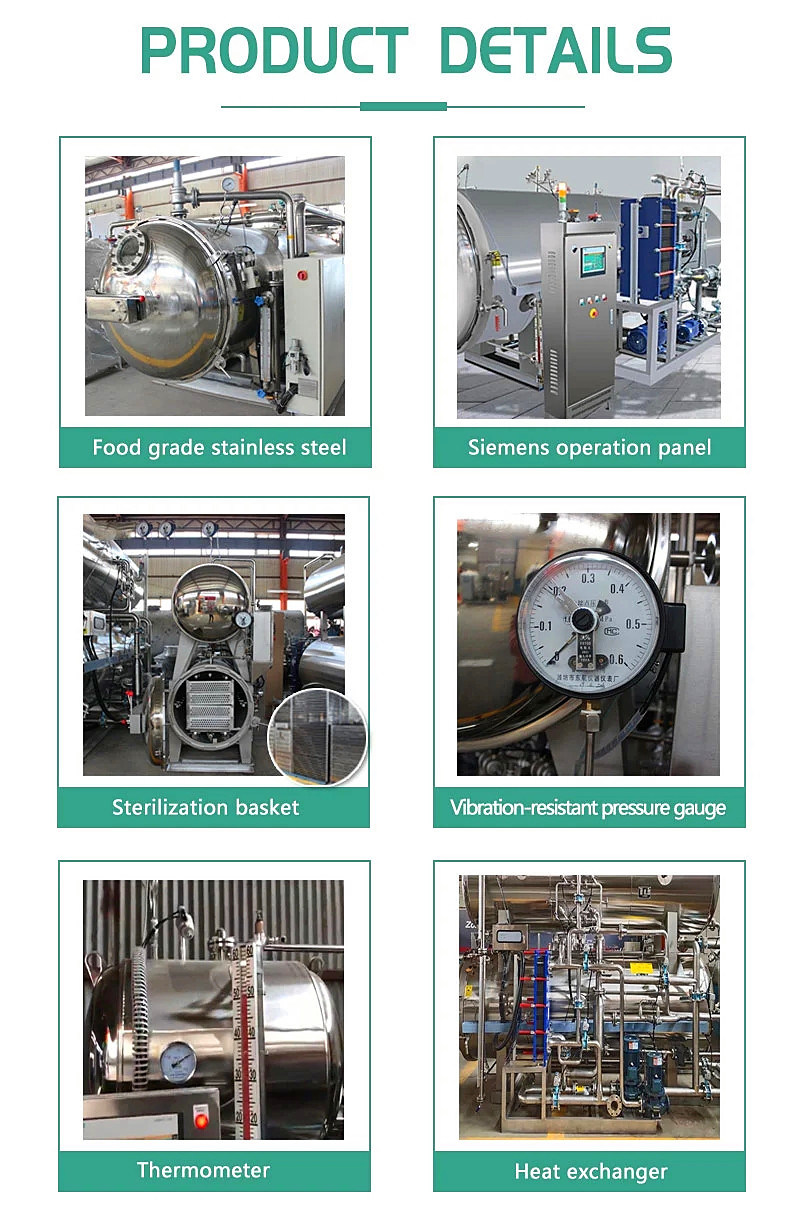

Introduction of Sterilization Pot

The sterilization principle is to inject the sterilizing water in the hot water tank at 121 °C into the pot (the temperature is 100-110 °C after neutralization), completely soak all the food, and the pure steam (vapor pressure 0.4-0.6Mpa) while the sterilizing and softening water is continuously circulated. It directly heats the sterilizing and softening water in the pot (replenish compressed air if necessary), and heats up quickly (at the initial temperature of 25 °C, it only takes 8-15 minutes to reach 121 °C), which ensures that the setting is guaranteed. Sterilization at temperature, and there is no phenomenon of bag up. Can produce good quality products in the shortest time.

The sterilizing pot is directly heated by steam, and is directly cooled by the softening water at room temperature. The soft multi-stage sterilizing process is intuitive and controllable, the temperature rises rapidly, and the temperature is lowered quickly, thereby ensuring that the product can achieve the predetermined bactericidal effect in the shortest time.

Compressed air can be used throughout the processing cycle. It can be programmed to pressurize and depressurize by automatically adjusting the valve according to the process requirements.

Application of Sterilization Pot

The sterilizer can be used not only for the sterilization of various beverages and foods, but also for products with high viscosity and large capacity. For example: eight-treasure porridge, meat sauce, canned meat, canned fish, rice and other products.

Parameters of Sterilization Pot

Parameters of Sterilization Pot| Model NO. | Diameter | Length | Capacity | Thickness | Design Temp | Design Pres |

| HK.09-1.8 B.4 | 900mm | 1800mm | 1.14m³ | 4mm | 121C | 0.35MPa |

| HK10-2. B.4 | 1000mm | 2000mm | 1.57m³ | 4mm | 121C | 0.35MPa |

| HK.12-2.2 B.4 | 1200mm | 2200mm | 2.48m³ | 5mm | 121C | 0.35MPa |

| HK.14-3 B.4 | 1400mm | 3000mm | 4.61m³ | 5mm | 121C | 0.35MPa |

Our Advantages

1. Accurate temperature control, excellent heat distribution

The temperature control module (D-TOP system) developed by DTS has up to 12 stages of temperature control, and the step or linearity can be selected according to different product and process recipe heating modes, so that the repeatability and stability between batches of products are maximized well, the temperature can be controlled within ±0.5ºC.

2. Perfect pressure control, suitable for a variety of packaging forms

The pressure control module (D-TOP system) developed by DTS continuously adjusts the pressure throughout the whole process to adapt the internal pressure changes of the product packaging, so that the degree of deformation of the product packaging is minimized, regardless of the rigid container of tin cans, aluminum cans or plastic bottles, plastic boxes or flexible containers can be easily satisfied, and the pressure can be controlled within ±0.05Bar.

3. Highly clean product packaging

The heat exchanger is used for indirect heating and cooling, so that the steam and cooling water are not in contact with the process water. The impurities in the steam and cooling water will not be brought to the sterilization retort, which avoids the secondary pollution of the product and does not require water treatment chemicals (No need to add chlorine), and the service life of the heat exchanger is also greatly extended.

DTS has experienced thermal verification experts and is a member of IFTPS in the United States. It fully cooperates with FDA-approved third-party thermal verification agencies. The experience of many North American customers has made DTS familiar with FDA/USDA regulatory requirements and cutting-edge sterilization technology.

4. Energy saving and envirnmental protection

A small amount of process water is quickly circulated to quickly reach the predetermined sterilization temperature.

Low noise, create a quiet and comfortable working environment.

Unlike pure steam sterilization, there is no need to vent before heating, which greatly saves steam loss and saves about 30% of steam.

Packaging & Shipping

Company Information

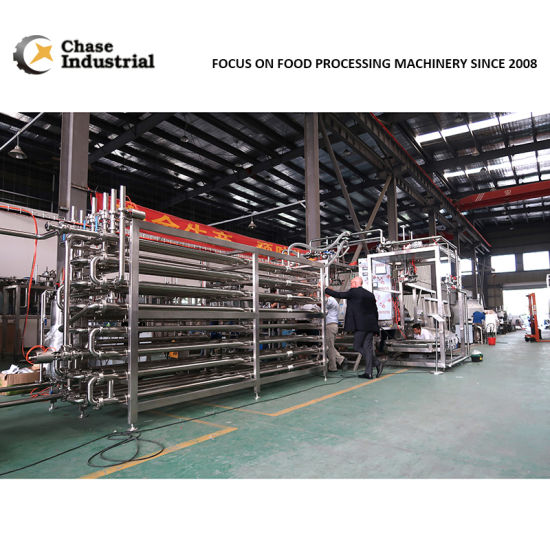

Qingdao Evertech Industry Co., Ltd. is aprofessional pressure vessel designer, manufacturer and exporter. We have manufacturing licenses forASME U, ASME U2,NB,PED, D1, D2 and A2 pressure vessels. Composed of more than 20 senior experts and professional engineers, the research and development team, with more than 20 years of professional experience, is committed to product design, development and program optimization, and can provide high-quality solutions according to users' requirements in different operating conditions. Company has cover an area of70000 manufacturing base and 15000 modern manufacturing plants, can provide customers both at home and abroad with composite autoclave, high pressure autoclave, high pressure reactor, AAC autoclave, deaerator, pouring tank pressure vessel productssuch as more than 800 sets, pressure vessel head more than 20000 sets high quality products and services, won widespread praise.

FAQ

1.What are the payment terms?

TT,L/C and trade assurance are acceptable,TT will be more appreciated,30% deposit before production,70% balance before shipment.

2.What is the delivery time?

At least 1 month after the deposit recipit,depend on how many machines included in the line.

3.How to pack the machine?

Standard packaging

4.How to install after the machines arriving destination?

Our engineer will go to customers site if you need,but need to pay installation fee accord with the contract.

5.What's the capacity you can do?

We always produce depend on customers' requirement.

Welcome to send me email any time.

The1year

The1year

Fruit Juice Canned Food Water Spr

Fruit Juice Canned Food Water Spr

Stainless Steel Material Mini Ret

Stainless Steel Material Mini Ret