- Model NO.:

- JY-MW series microwave equipment

- Certification:

- CE

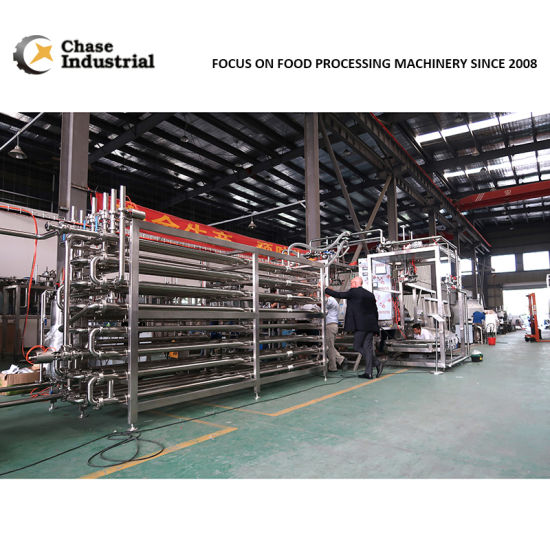

Bottled drinks Bagged snacks rapid continuous sterilization machine packed food microwave sterilization equipmentAutomatic Industrial Microwave Sterilization Equipment Vegetables Preserved Fruit Condiments Jam Seafood Snacks Sterilization Machine

Continuous tunnel type microwave food and beverage heating sterilization machine

Product Description

The process time of the microwave sterilization equipment is much shorter than the traditional heating and sterilization time. It allows the food to be heated uniformly inside and outside at the same time. Generally, the preheating time required for the food to reach the sterilization temperature is not needed.

Moreover, the factors of microwave sterilization are not just thermal factors There are also non-thermal effects. Therefore, according to the characteristics of microwave sterilization that is different from traditional heating sterilization, the following sterilization processes can be used.

Advantage

1. Intermittent microwave irradiation

The advantage of the microwave intermittent irradiation method is that it can achieve a sterilization effect with a high electric field intensity in a short time. However, high electric field intensity and power density will place higher requirements on the breakdown resistance of microwave equipment and processed materials, such as the need for precision These requirements, such as controlling irradiation time, will increase the cost of microwave equipment.

2. continuous microwave irradiation

In order to make up for the shortcomings of intermittent microwave irradiation, a continuous microwave irradiation sterilization process with a lower field strength and an appropriate extension of the microwave irradiation time can be used.

Generally speaking, the power density in the box of the tunnel box type microwave equipment is low, which can be suitable for the above process requirements. Under the premise that the material allows temperature and heating time (heat resistance), appropriately extending the irradiation time will help strengthen the sterilization effect, and at the same time, it can make the material heating state even, so there is enough time to make the material inside and outside with the help of heat conduction. Reduced temperature differences.

3. microwave multiple rapid irradiation and cooling

The purpose of this sterilization process is to quickly change the ecological environment temperature of microorganisms and sterilize by microwave irradiation for many times, so as to avoid leaving the material continuously at a high temperature for a long time. Advantageously, the process is suitable for sterilization of temperature-sensitive liquids, such as sterilization and preservation of beverages and rice wine. The sterilization temperature conditions can be controlled by setting different sterilization objects.

Detail of machine

Microwave heating is the overall heating, that is, heating, the internal and external heating of the material, not the heat of the traditional heating method is conducted from the surface layer of the material.Fast, efficient, safe and environmentally friendly.

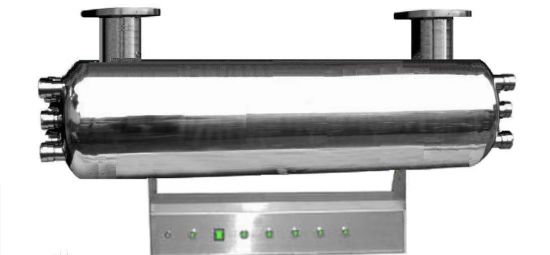

| ProductName | Spice microwave sterilizer |

| Devicetype | Transmissionbelt |

| Microwavefrequency | 2450±50MHz |

| Power | 20kw |

| Transmissionspeed | 0-5m/minute |

| Inputvoltage | Three-PhaseAC380V |

| Weight | 1t |

| Cabinetcolor | Silverhwhite |

| Thewholematerial | Industrialgradestainlesssteel |

| Microwaveleakagelimit | ≤1mW/cm² |

| Ambinettemeperature | -10-40°c |

| working time | 24hours |

Functions

1.chemical material,medicine tablet or pill,such as watered pills,water-honey bolus,honeyed bolus,condensed pill and Tibetan pill,etc.

2.all kinds of teas,herbs, flowers, green leaves,etc.

3.various dried meat, like beef, pork, chicken,duck, fish etc.

4.powder for various material,such as spices, other food additives.

5.agricultural products,such as china date,nuts,grains,peanut,etc.

6.snack food, fruit seeds, grains, peanuts, chips,etc.

Company Profile

Company ProfileWe use international advanced scientific and technological indicators, monitoring and control equipment, to constantly optimize the excellence of microwave equipment details, combined with the excellence of equipment in various industries at home and abroad to enhance the comprehensive competitiveness of products.

1). Free consultation service before, during, and after sales.

2). Free project planning and design services upon clients' special demands.

3). Debugging and inspecting of equipment until everything is functional before leaving the factory.

4). Overseas installation and training of equipment maintenance andoperating personally.

FAQ

FAQQ: How long is your delivery time?

A: Generally speaking, it is 7 days if the machines are in stock. Or it is 25 days if the goods are out of stock.

Q: Could you supply all the parameters about the machines?

A: Of couse. We are delighted to supply all the informtion that you want to know.

Q: How about the after sale service?

A: We will send our engineers to your factory for installation and training.

Q: How should I know the process of manufacturing if we pay the down payment?

A: We will supply you an exact delivery time as soon as we received your deposit. During the manufacturing, we will make reports for you to let you know the process.

Bottled drinks Bagged snacks rapid continuous sterilization machine packed food microwave sterilization equipment

Stainless steel microwave sterilization equipment Dehydrated vegetables preserved fruit condiments jam seafood snacks sterilization machine

Continuous tunnel type microwave food and beverage heating sterilization machine

Bottled drinks Bagged snacks rapid continuous sterilization machine packed food microwave sterilization equipment

The1year

The1year

Microwave Spice Chili Pepper Tea

Microwave Spice Chili Pepper Tea

PLC Control Black Sesame Seed Mic

PLC Control Black Sesame Seed Mic

Ground Coriander Powder Microwave

Ground Coriander Powder Microwave

Industrial Environmental Protecti

Industrial Environmental Protecti

Microwave Food Herbs Spice Tea Se

Microwave Food Herbs Spice Tea Se

Industrial Spices Drying Machine

Industrial Spices Drying Machine