- Model NO.:

- jinrong

- Certification:

- CE, ISO9001

Characteristics:

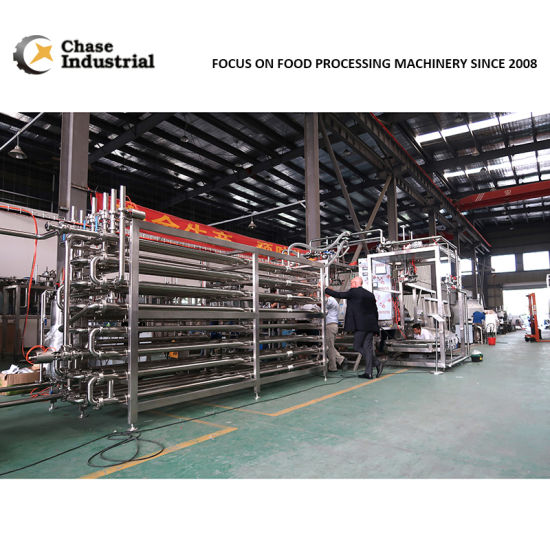

This machine adopts advanced technology from chemical industry- Static Mixing device (also named carbonization device). The contact surface of gas and liquid is full and the resistance is low, thus featuring high efficiency and low power consumption. Its structure is also concise and employing reliable multi-grade carbonation pump which is quiet and controlled by frequency convertor for start or run, thus ensuring the good performance of the complete equipment.

Precise mixing proportion and adjustable: To adjust the capacity or mixing proportion, no need to change any parts.

3) This machine adopts CO2 reflux for deoxidation, featuring economic use of CO2 and good effect of deoxidation.

4) This machine can conveniently adjust volume of carbonation in terms of the requirements of beverage's carbonation. It can be done through suitable operation and adjustment to complete the procedure.

5) This machine has full automatic controlling system; It has advantages of concise structure, harmonious working action, continuous production, and high automatic performance.

6) This machine has cleaning procedure in original position and favorable structure. Convenient chemical disinfection or heating disinfection or cleaning with clean water can be carried out according to hygiene requirements of foods.

Systematic instruction

For cooling water stage

Cooling water going through filters, multi-grade pump and check valve, gets to deaerator tank for Deoxidation and pre-carbonation. Like spray on filling material cooling water is mixed with CO2 and O2 in water is exchanged, thus improving the volume of CO2 in the beverage and prolong its quality duration.

For syrup stage

Cooling syrup going through filters, multi-grade pump and check valve, gets to syrup tank, whose liquid level will be automatically controlled by floating ball liquid level controlling device for start or stop of syrup pump.

(3)For carbonation pump import stage

Going through water proportion valve, check valve, pre-carbonated water gets to entrance of carbonation pump as well as going through syrup proportion vale, ball valve and check valve, syrup gets to. Before being pumped outwards pre-carbonated water and syrup are mixed with constant proportion.

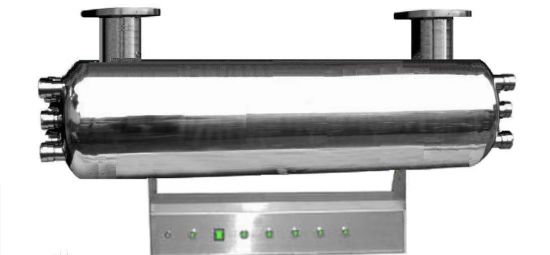

(4) For carbonation Pump exit stage

Carbonation pump pumps outwards the proper mixing of syrup and pre-beverage with high pressure through volume valve, flux gauge, check valve and static mixing device to finished tank. Pre-beverage and CO2 are jointed at the import point of static mixing device with corrugated sections which make the contact of pre-beverage and CO2 full and efficient. And then it goes to finished tank for retaining pressure, CO2 will be fully dissolved in beverage.

(5) Electrical controlling system

Relays and contactors are employed in electrical system to automatically control all the processes such as water-in, syrup-in, CO2-in, CO2 reflux and over-pressu

The1year

The1year