- Model NO.:

- GLX2-25

- Certification:

- CE, GMP, ISO

Introduction

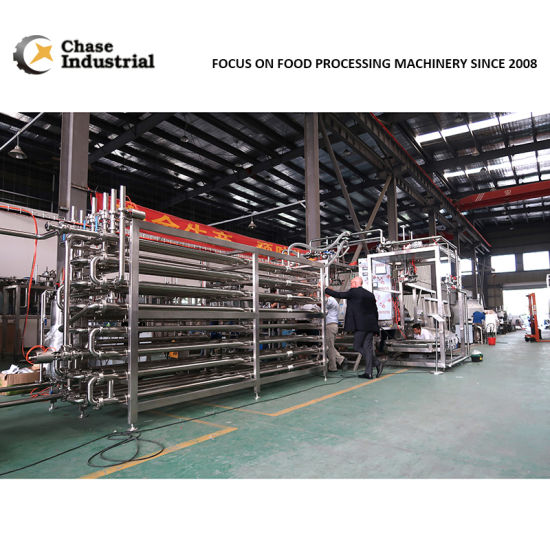

The compact line is consist of QCL series vials washing machine, ASMR 620 circulating heated air sterilizing oven and KGF series liquid filling and stoppering

Machine for vial. And each machine can be used stand alone. It is apply for filling 2-25ml vial, it can achieve the processing such as ultrasonic washing, three time water washing(two time circulating water washing, one time fresh water, three-tree air spraying, drying and sterilizing, cooling, Liquid filling, protection gaseous filling(compressed air filling or nitrogen filling), and stoppering.

Features

1. Mechanical gripper holds the ampoule around the washing machine, applied to different size of vials

2. Ampoule does not stop while washing process, the water and air nozzle following the moving ampoule and insert into ampoule, good quality washing effect, and WFI economy, set the anti-oscillating device for washing machine

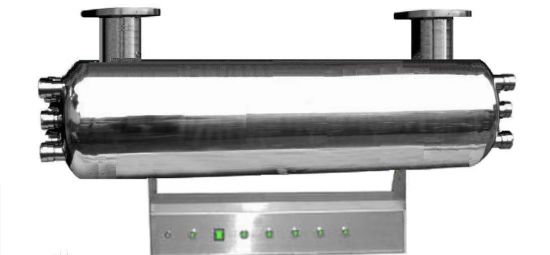

3. The circulating water pipe and fine washing water pipe is sparated fitted, there is no cross-contaminationfunctions of faults.

4. Add buffering block in front of the spiral screw to prevent ampoule broken and protect the spiral screw

5. Bottle out-feeding section is adopted cellular-belts to transfer bottle, it3d reliable

6. Circulating heating air exert on the ampoule while sterilizing, excellent temperate distribution, energy economy

7. Protecting for HEPA while power failure suddenly, safe running.

8. Water cooling system is optional; It can decrease fresh air supply from the washing room, and reduce the risk from wind differential pressure imbalance, good cooling effect.

9. Wind pressure auto balancing regulating system is optional, it can make the air flow from heating section not move and steady`, and it can avoid series trouble, such an the temperature getting increasing in filling room and washing room

10. Set DOP testing port for Sterilizing tunnel(including wind pressure testing, wind speed testing, and partical testing)

11. Adopt round even-pace wheel at ampoule in-feed station instead of sector block to reduce ampoule breaking

12. The sterilizing function for cooling section is optional for FAD requirement.

13. The inner surface of the sterilizing tunnel can be clean.

14. Filling machine is adopted horizontal type cellular-belts to transfer bottle, it is fast and accurate, and easy to change format for different size of vial.

15. There is certain distance between machine table and The plane which bottom of the vial situated, it is easy for wind of laminar flow crossing, and prevent the liquid contamination from turbulent flow

16. Adopt the horizontal stopper feeding at Stoppering station, and use horizontal disk to inhale and hold stopper, it is easy to observe and add the stopper, and feature of high speed feeding.

17. For filling and sealing machine, the ceramic pump. SS pump, creeping pump is optional

18. Stop filling if there is no vial, stop stopering if there is no vial

19. Servo system to be optional for filling(Delta, Mitsubishi, Rockwell)For filling and sealing machine, the servo system is optional for driving filling pump.

PLC control the whole machine, inverter and touch screen is used in control system, so the machine is stable and reliable during running. The touch screen can display running status of all unit machine, water pressures, gas pressures and temperatures of all controlled point, can display the status of all switches and its faults, faults self-diagnosis, faults analysis and its solutions. The Washing-sterilizing-filling and sealing inter-linkage balancing device, All of these make the compact line in automatic control, and makes producing process stable and reliable. Siemens, Rock Well, Mitsubishi or Delta is optional for the electrical control system.

Max output 39000b/hour for 2ml vial

The1year

The1year