- Model NO.:

- HY-Filling Scott

- Certification:

Located in Zhangjiagang City of Suzhou, the Yangtze River Delta, our company has 50million RMB fixed assets, covers an area of 30,000 square meters, with a more than 30 professionals team to design and develop, is a key professional enterprise, which integrates development, research, design, manufacture, technology service and marketing, to manufacture complete sets of wine, beverage and sticky filling equipments.

We are adhering to the principle of "market-oriented, quality as the main line, service as the guarantee and repute as the basis". HY-Filling follows ISO9001:2000 international quality management system, it has established and improved the quality assurance system to ensure the quality and performance of the company's products. The Development department of HY-Filling, with advanced technologies, has more than 30 full-time design and development engineers. HY-Filling's technologies mainly sources from Italy, France, Germany, Switzerland and Japan; furthermore, a set of liquid filling production line with advanced technology and high starting-point has been developed combined with China's basic conditions, its high automation level achieved the one in late nineties. Department of After-sale Service of HY-Filling adheres to service goal of "Customers' needs are urgent, customers' requirements are important, customers' satisfaction is the aim", provides the services of equipment installation guidance, products testing, maintenance and spare-parts supplying, consultation, complaints, regular visit every 24 hours.

HY-Filling has a network of customers for the complete set of beverage bottling lines more than 500 which spreads 30 more domestic provinces, municipalities, autonomous regions and the United States, Britain, Japan, the Middle East, Southeast Asia, Africa, Russia, CIS, South Africa etc. Besides the production and sale of equipments, HY-Filling provides various technical services to help users design equipment layout, answer users' consultation, train users' staff and provide practical operation guidance.

Our Group Company is a Chinese Stock Public Company who can provide TURN-KEY Solution for Water Beverage and Dairy, can be packed by PET, Glass, aluminum CAN, Aseptic Carton, etc.

We also offer customer value added service, offering customer packaging raw material like preform label film and even beverage formula,etc.

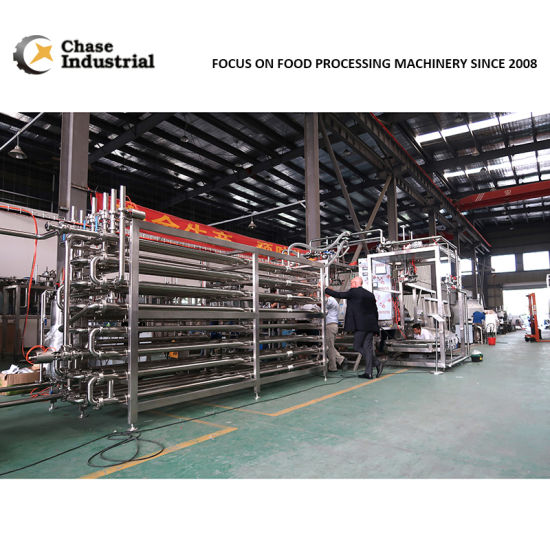

Sugar Melting and Mixing System

1) CE certificate

2) ISO9000: 2000 Certificate

3) Automatic system

4) High efficiency, easy maintenance

Our Company is a leading company manufacturing blowing filling and packaging machines, for PET bottle filling, 5 Gallon Filling, Glass bottle filling and aluminum CAN filling.

We also offer customer value added service, offering customer packaging raw material like preform label film and even beverage formula,etc.

VIDEO of PET Bottle filling line: http://youtu.be/fsGJHidZqVA

VIDEO of Glass Bottle Filling Plant: http://hy-filling.en.made-in-china.com

VIDEO of Aluminum CAN Filling Plant: https://hy-filling.en.made-in-china.com

Main configuration:

| Material of rotary tray and machine platform of rinser and filler | Stainless steel SUS304 |

| Main motor | ABB (Switzerland)/ SEW (Germany) |

| Sliding bearing | Igus (Germany) |

| Frequency inverter | Danfoss (Denmark) |

| Touch screen | SIEMENS (Germany) |

| PLC | SIEMENS (Germany) |

| Contactor | SIEMENS (Germany) |

| Breaker | SIEMENS (Germany) |

| Air switch | SCHNEIDER (France) |

| Pneumatic components | CAMOZZI (Italy) |

| Seals | SEALTECH (HK) |

| Photocell switch | Omron, Keyence, P+F, SICK(Japan /Germany) |

| Proximity switch | Omron, Keyence, P+F, SICK(Japan /Germany) |

Sugar is one of the main ingredient of fruit juice beverage. The process of sugar cane dissolved in water is called sugar dissolving operation.

Sugar dissolving system generally contains sugar powder conveying, sugar powder dissolving, syrup sterilizing, syrup filtration& cooling and syrup storage unit, etc. In some circumstances, deaeration treatment to syrup is required. The typical hot dissolving process is using 85 degree water and hold 10 minutes, then to cool hot syrup to required temperature (less than 40 degree) step by step.

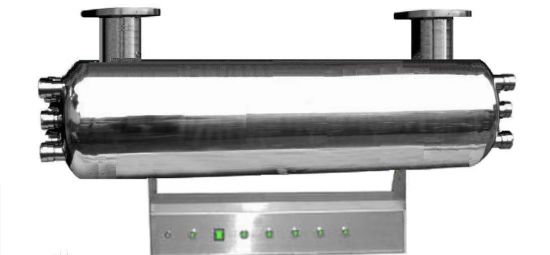

We offer turn-key project for beverage preparation system, including extracting, sugar melting, blending, UHT sterilizing/pasteurizing, homogenizing etc, with strong technical support from our factory and relative industry from home and abroad. The best quality equipments, best technic and best installation and commissioning team will make perfect project for customer.

Certification

Our Services And Strength

This company abides by the business concept of "Cutomers ever in the highest postion and cooperation ever with good faith".This company has made constant efforts to perfect its service system and has contributed positive efforts to establish harmonious cooperation partnership with our customers in the spirit of mutual benefits.With the severe market tests experienced over the last few years,the above bussiness concept has become a solid foundation stone for the existence and the long-term development of HY-FILLING company.

Installation and commissioning

After the equipments arrived buyer's workshop, the buyer should take it's place for each equipment according to the supplied layout; the seller will send the experienced technician to guide the installation and debugging and trail production, and fulfil the designed capability within the designed time.

Training

The seller will supply technical training to the buyer. The training is includes: equipment structure and maintenance, control and operation. After training, the technicians of the buyer will grasp relevant operation and maintenance skills, and could adjust the technologies more skilled, and can deal with all kinds of malfunction in time.

After-sales service

1) After qualified of the equipment, the seller will supply one year guarantee, control system one year guarantee, free charge for wearing parts, and other spare parts with cost price. Within guarantee period, the technicians who accepted training should strictly obey the requirements asked by the seller to operate the equipments and maintenance, to find the common malfunctions and fault clearing in time; if the technicians of the buyer couldn't solve the problems themselves, the after-sales department will supply long range guide service by phone; if relevant measurements couldn't solve the problems, the seller will send the technicians to the buyer factory, clear the fault or relevant technical problems on site, the charges will reference to the installation and debugging charges.

2) After guaranteed, the seller will supply widely favorable technical support, after-sales service for the lifetime: favorable price for the wearing parts and other spare parts.

The1year

The1year