- Model NO.:

- Certification:

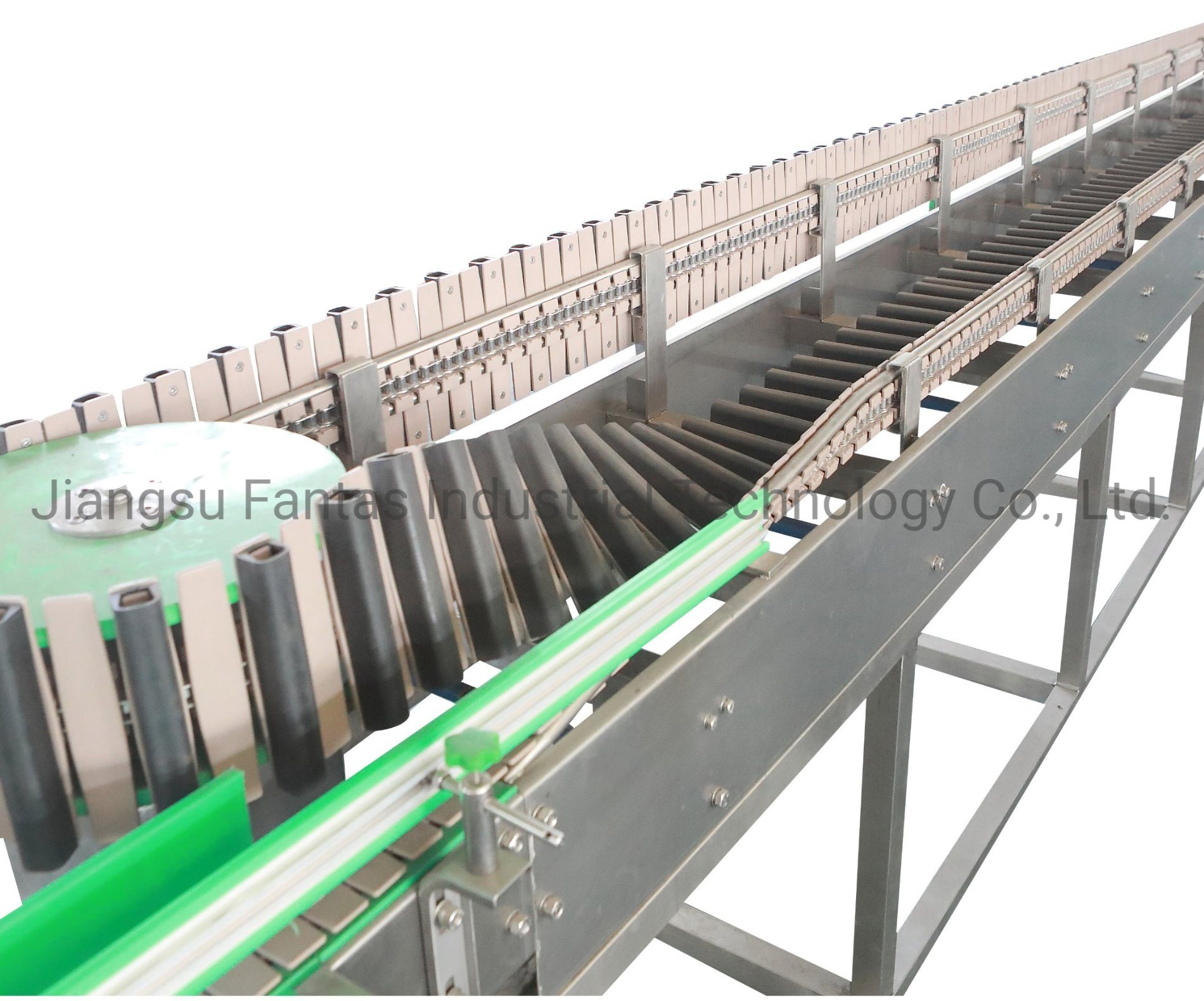

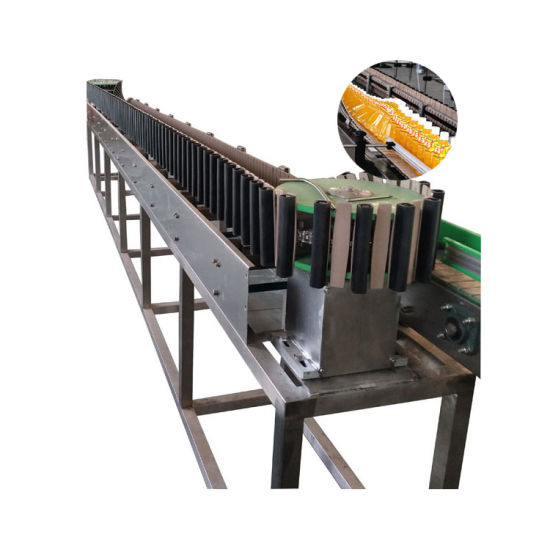

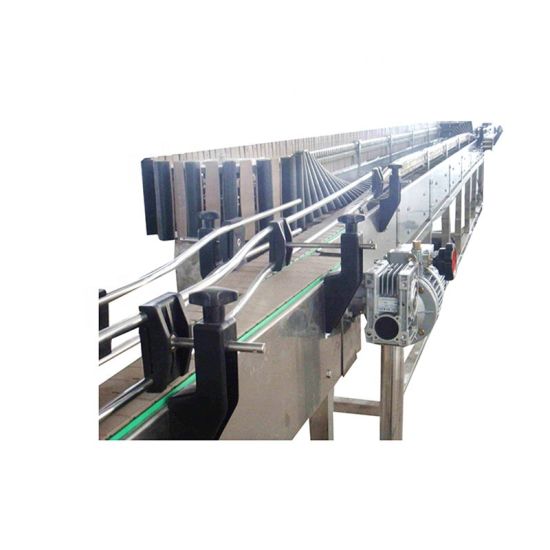

The inverted bottle sterilizer is to turn the bottle to 96° or 110° during transportation, and use the temperature of the beverage after high temperature filling (≥ 80C) to sterilize the bottle cap. Sterilization time can be 30-40 seconds according to the requirements. Adopt imported stainless steel chain and high temperature resistant plastic chain plate. This machine has the advantages of simple structure, convenient operation and energy saving. It is an ideal cap sterilization equipment for hot filling of tea drinks and fruit juice.

Introduce

The machine is mainly used for fruit juice beverages after thermal bottling and capping for sterilization on clearances on bottles mouths and bottle cap, which cannot be touched by high-temperature materials. To the products after bottling and capping, the machine shall turn the bottle by 90 degrees automatically to horizontal direction, by material temperature, to sterilize internal wall of water of bottle cover. imported transfer chain is adopted, stable and reliable, without damages on bottle body, and transfer speed is stepless adjustable.

Technical parameters

| Model | 06 | 09 | 12 | 15 | 18 | 20 | 24 |

| Production capacity | 6000 | 8000-9000 | 12000 | 15000 | 18000 | 20000 | 24000 |

| Total power | 1.5±0.55 2.2±0.75 | ||||||

| Total length | 10 | 11 | 14 | 16 | 19 | 19 | 22 |

| Weight | 9500 | 10000 | 11500 | 12500 | 14000 | 14000 | 15500 |

Character

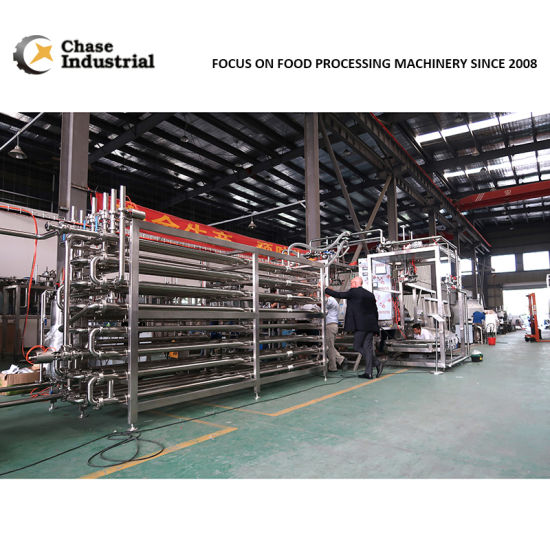

The inverted sterilizer for filled bottle neck and mouth is suitable for tea, fruit juice drinks, widely used in juice production

line.

The titling sterilization machine is especially used for second sterilizing in juice processing plant. It is not only sterilizing

the material but the caps. It is the essential sterilizing machine for the hot filling production line.

Advantage

1.The machine is mainly used to sterilize the interspaces where can't be reached by high temperature materials in the mouths or capsules of juice or tea bottles whichhave been filled and sealed.

2.After the product being filled and capped, the bottle shall be inverted 90°automatically and put flatware by the machine, and the inner of the bottle shall be sterilized by high temperature of the materials and then bottle shall be put vertically and enter into the shower and cooler.

3.The machine runs steadily and reliably and does no harm to the bottle body while the transmission speed is adjusted steplessly.

Specifications

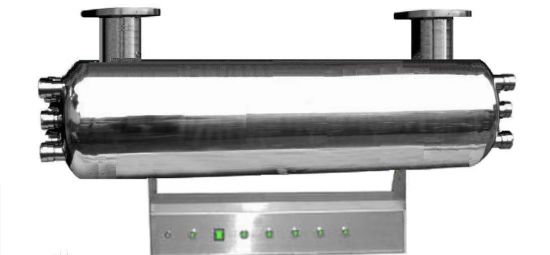

| Capacity | 1-5T/H | Cooling time | 10-25 minutes speed infinitive adjusting |

| Sterilization temperature | < 98ºC It can be adjusted according to order | Steam pressure | 0.4 Mpa |

| Sterilizing time | 10-35 minutes speed infinitive adjusting | Chain belt speed | 0.17 -10m/min speed infinitive adjusting |

| Cooling temperature | 20ºC | Dimensions | 1600x2600x 2000 mm |

The1year

The1year