- Model NO.:

- E-0701

- Certification:

- CE, CSA, ISO9001, ASME, FDA

ntent="" style="background-color:#d6dce3;padding:0 10px;margin:0;line-height:36px;text-align:left;">Product Description

The pilot retort is a multifunctional test sterilization retort, which can realize sterilization methods such as spray (water spray, cascade, side spray), water immersion, steam, rotation, etc. It can also have any combination of multiple sterilization methods to be suitable for food manufacturers' new product development laboratories, formulating sterilization processes for new products, measuring FO value, and simulating the sterilization environment in actual production.

ntent="" style="background-color:#d6dce3;padding:0 10px;margin:0;line-height:36px;text-align:left;">Certifications

Retort is designed and produced according to the requirements of GB150-2011 <steel pressure vessel manufacturing standard>. DTS is identified and has passed through ISO9001, ISO14001 system authentication and also passed America ASME as well as SGS, TUV, BV, EAC rated.

ntent="" style="background-color:#d6dce3;padding:0 10px;margin:0;line-height:36px;text-align:left;">Our Advantages

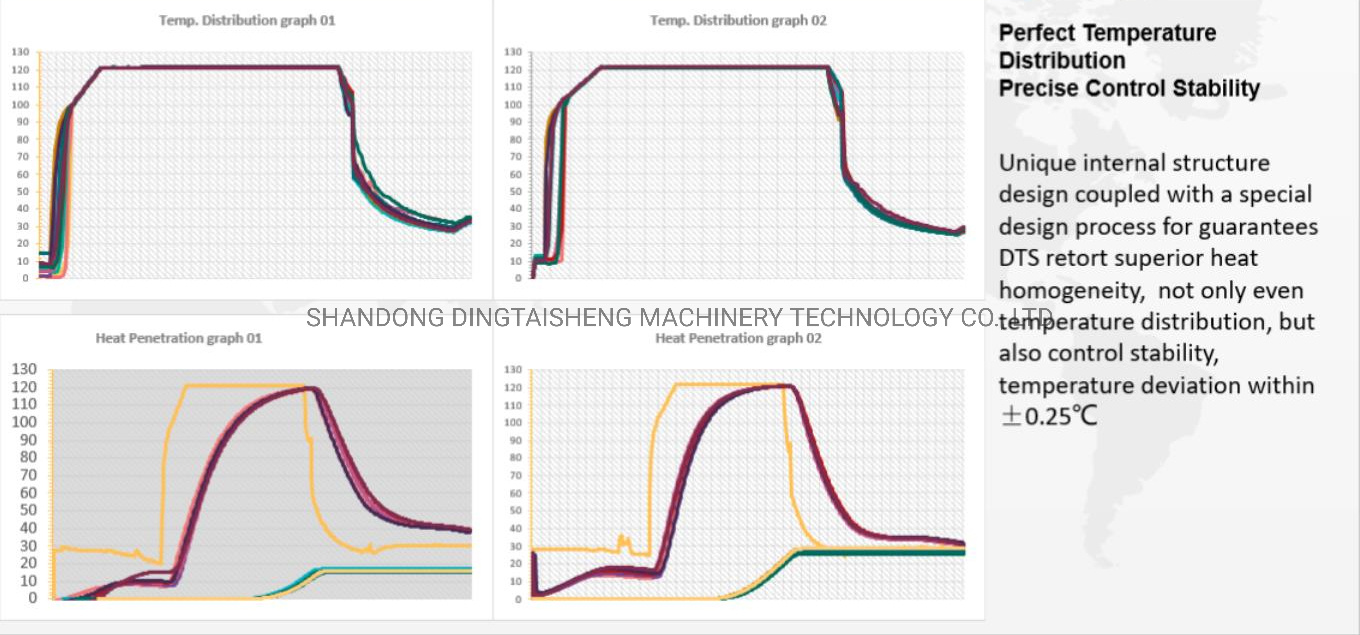

1. Accurate temperature control, excellent heat distribution

2.Highly clean product packaging

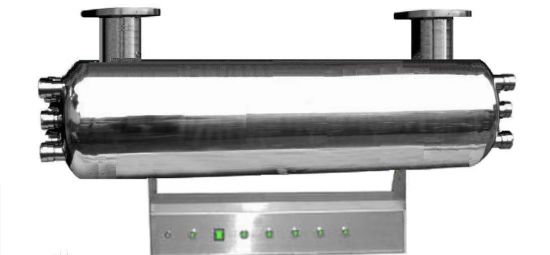

The heat exchanger is used for indirect heating and cooling for the water spray type, so that the steam and cooling water are not in contact with the process water. The impurities in the steam and cooling water will not be brought to the sterilization retort, which avoids the secondary pollution of the product and does not require water treatment chemicals (No need to add chlorine), and the service life of the heat exchanger is also greatly extended.

3. Energy saving and environmental protection

The self-made high-quality spiral wound heat exchanger has high heat exchange efficiency and saves energy. A small amount of process water is quickly circulated to quickly reach the predetermined sterilization temperature. Low noise, create a quiet and comfortable working environment.

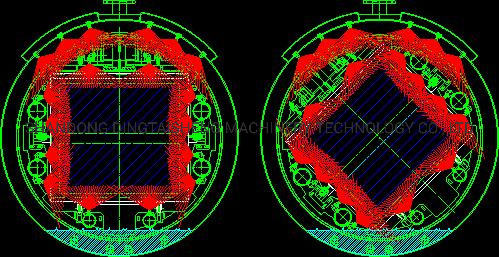

4. DTS patent system: Fixed jets of water rain distributed on the upper part of the retort. While rotary jets of water rain distributed on the crate's walls of the retort.

ntent="" style="background-color:#d6dce3;padding:0 10px;margin:0;line-height:36px;text-align:left;">DTS Technologies

1.Spiral-tube heat exchanger made of stainless steel

2.Full automatic linear control system

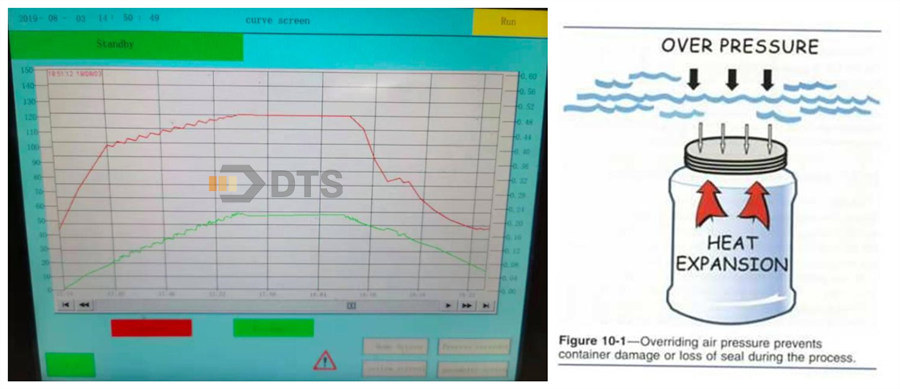

DTS self-studied patented technology D-TOP system can be sensitive to temperature.It can automatically calculate the pressure changes inside the container according to the temperature.And then automatically adjust the pressure inside the retort to get the pressure balance between container internal and external.So it can prevent the package's deformation, keep the package shape.Especially be suitable for aluminum tray products.Pressure was controlled in +/ -0.05 bar with compressed air intake valve and exhaust valve.

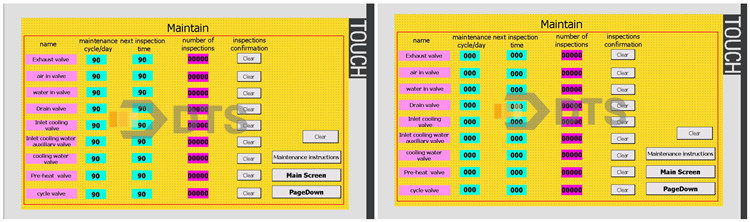

3. maintence cycle and alarm:For main valves, we set the maintenance cycle and time in the PLC, when it arrives, there will be alarm appear to notice.

ntent="" style="background-color:#d6dce3;padding:0 10px;margin:0;line-height:36px;text-align:left;">Product Parameters

| Model | Effective diameter | Effective length | Dimension | Qty of food baskets | Design Temperature | Design Pressure | ||

| L | W | H | ||||||

| DTSE/07-1 | 700 | 500 | 2204 | 1706 | 2045 | 1 | 147ºC | 3.5bar |

| DTSE/09-1 | 900 | 600 | 3323 | 1800 | 2584 | 1 | ||

ntent="" style="background-color:#d6dce3;padding:0 10px;margin:0;line-height:36px;text-align:left;">Packaging & Shipping

ntent="" style="background-color:#d6dce3;padding:0 10px;margin:0;line-height:36px;">Company Profile

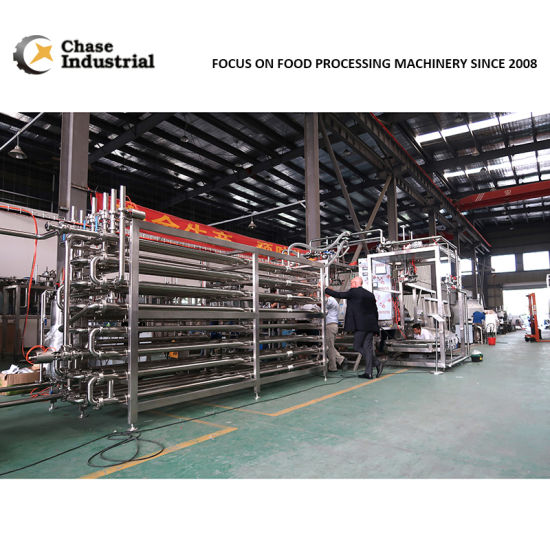

The predecessor of DTS was founded in China in 2001.In the year of 2015 and 2016, we cooperate with Italy Laveti and Gemany Innova.We introduced their technology and produce in China DTS.

DTS is the most influential supplier of retort equipment in the food and beverage industry in Asia.Our goal is to become the top international brand in food sterilization industry.We have highly experienced and talent mechanical engineers, design engineers and electrical software development engineers.It is our aim and responsibility to provide the best products and services as well as excellent working environment for our customers.We love what we do, and we fully understand that our value lies in helping customers create value.To this end, we are cautious to develop and design various flexible and customized solutions to meet different customer needs through well communication.

The1year

The1year

Automatic Batch Retort System/Ste

Automatic Batch Retort System/Ste

Water Spray Retort Equipment/Auto

Water Spray Retort Equipment/Auto

Rotary Water Immersion Retort/Aut

Rotary Water Immersion Retort/Aut

Direct Steam Retort/Autoclave/Ste

Direct Steam Retort/Autoclave/Ste