- Model NO.:

- CNME060341

- Certification:

- CE, ISO13485

Description:

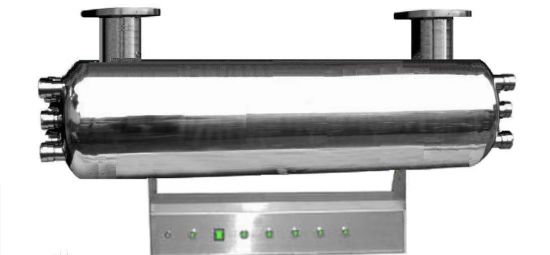

This series of pulsation vacuum sterilizer uses saturated steam as its sterilization medium. The saturated steam releases a large amount of latent heated physical properties in the stage of condensation, which presents items to be sterilized with a state of high temperature and humidity. After a period of insulation in such status, sterilization is achieved. The application of pulsating vacuum exhausting has successfully eliminated temperature influence from cold air, and helping the sterilization items to be dried by means of vacuum and dehumidification between the jacketed layers.

Main Parameters and Utilities:

| Design pressure | 0.245MPa |

| Design temperature | 139ºC |

| Vacuum | -0.09 MPa |

| Water source pressure | 0.15-0.3 MPa |

| Steam pressure | 0.3-0.7 MPa |

| Working pressure | 0.225 MPa |

| Working temperature | 105-134ºC |

| Temperature equilibrium | ≤±1ºC |

| Compressed Air pressure | 0.3-0.7 MPa |

| Power | AC380V,50HZ The three-phase and five-wire system AC380V,50HZ |

Size & Utilities:

| Capacity | Overall size L×W×H (mm) | Chamber size L×W×H(mm) | Steam consumption(kg) | Tap Water consumption (kg) | Power(kw) | Net weight (kg) |

| 250L | 1100*1350*1900 | 800*600*600 | 18KG | 35KG | 2+24KW | 900Kg |

| 360L | 1300*1350*1900 | 1000*600*600 | 25KG | 40KG | 2+24KW | 1000 Kg |

| 600L | 1500*1360*1950 | 1200*610*910 | 30KG | 45KG | 3+36KW | 1400 Kg |

| 800L | 1800*1360*1950 | 1500*610*910 | 40KG | 50KG | 3 KW | 1600 Kg |

| 1200L | 1750*1440*1950 | 1450*680*1180 | 48KG | 55KG | 4 KW | 1800 Kg |

| 1500L | 2150*1440*1950 | 1850*680*1180 | 55KG | 60KG | 4 KW | 2000 Kg |

| 2000L | 1950*1750*2200 | 1600*900*1400 | 65KG | 65KG | 4.5 KW | 2500 Kg |

| 2500L | 2300*1750*2200 | 1950*900*1400 | 75KG | 75KG | 6 KW | 3000 Kg |

| 3000L | 2700*1750*2200 | 2400*900*1400 | 90KG | 90KG | 8 KW | 3500 Kg |

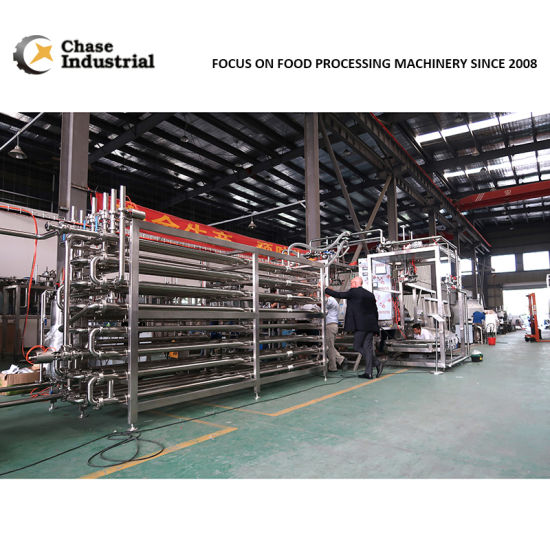

Structure and Characteristic of The Equipment:

Body of the sterilizer:

It is designed and manufactured in accordance with GB150 "the Pressure Vessel", GB 8599 "The Technical Requirements of Large Steam Sterilizer--Automatic Control Protocol", and TSG R0004 the "Safety and Technology Specification for Fixed Monitor Vessels" and related inspection procedures.

Tank of the horizontal rectangular double-deck structure is made from S30408.

Door sealing: Pneumatic sealing; both doors are interlocked and completely conform to the requirements of the specification.

The equipment has standard GMP authentication interface.

Sterilizer piping system: the pipeline is designed with the best configuration. By employing imported parts and quality domestic brands into main components.

Sterilizer control system: with the adoption of Siemens PLC plus Siemens touch screen, this system is easy to implement the program selection, parameter setting, equipment operation, report processing and other functions. It has perfect safety measures. The F0 value and the temperature time gives double guarantee for sterilization. A single parameter control is also available. It has a perfect sterilization records.Company Profile

1.How to place order ?

Email us your order detail or u can directly place your order from our website.

2.How to ship them?

A:Ship them by our forwarder or your appointed shipping agent.

3. What's your payment terms & payment method?

30% deposit by T/T, 70% should be balanced before delivery. (If total less than USD5000, our term is 100% deposit by T/T.)

Support multiple payment methods, such as T/T, Credit cards, West Union,Credit/Debit Card, Paypal, Apple Pay, Google Pay....

4.When goods will be ready after payment?

Usually 2-5 working days for small quantity, and about 2-4 weeks for large quantity order; our sales manager will inform you the lead time when make quotation.

5.How to ensure the goods quality?

All goods must be checked by QC, if you get a useless product, we will replace a new one in following orders.

6.Can I OEM?

Sure, we can OEM product, package, user manual as your designing draft, to help client to expand theirs brand is one of our main business.

The1year

The1year